PDF Publication Title:

Text from PDF Page: 127

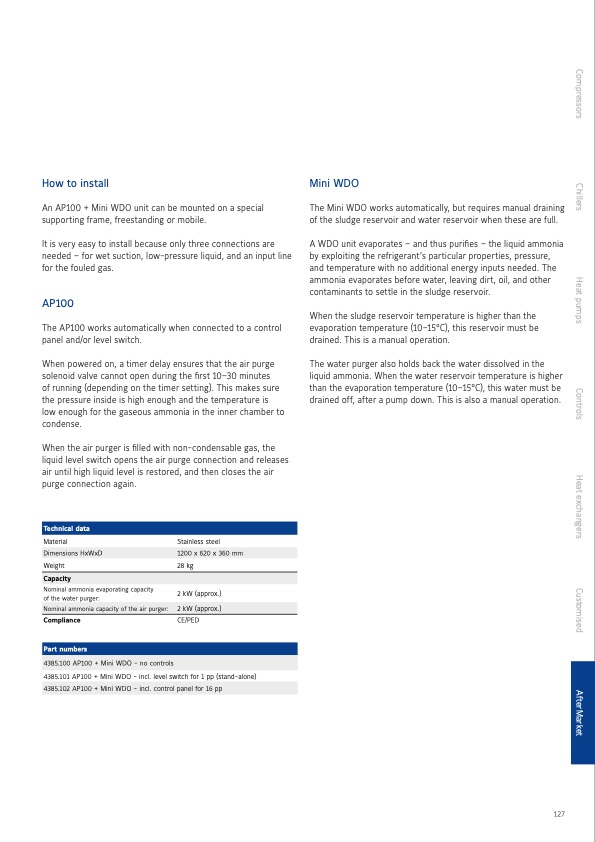

How to install An AP100 + Mini WDO unit can be mounted on a special supporting frame, freestanding or mobile It is very easy to install because only three connections are needed – for wet suction, low-pressure liquid, and an input line for the fouled gas AP100 The AP100 works automatically when connected to a control panel and/or level switch When powered on, a timer delay ensures that the air purge solenoid valve cannot open during the first 10–30 minutes of running (depending on the timer setting) This makes sure the pressure inside is high enough and the temperature is low enough for the gaseous ammonia in the inner chamber to condense When the air purger is filled with non-condensable gas, the liquid level switch opens the air purge connection and releases air until high liquid level is restored, and then closes the air purge connection again Mini WDO The Mini WDO works automatically, but requires manual draining of the sludge reservoir and water reservoir when these are full A WDO unit evaporates – and thus purifies – the liquid ammonia by exploiting the refrigerant’s particular properties, pressure, and temperature with no additional energy inputs needed The ammonia evaporates before water, leaving dirt, oil, and other contaminants to settle in the sludge reservoir When the sludge reservoir temperature is higher than the evaporation temperature (10–15°C), this reservoir must be drained This is a manual operation The water purger also holds back the water dissolved in the liquid ammonia When the water reservoir temperature is higher than the evaporation temperature (10–15°C), this water must be drained off, after a pump down This is also a manual operation Technical data Material Weight Nominal ammonia evaporating capacity of the water purger: Compliance Stainless steel 28 kg 2 kW (approx ) CE/PED Dimensions HxWxD 1200 x 620 x 360 mm Capacity Nominal ammonia capacity of the air purger: 2 kW (approx ) Part numbers 4385 100 AP100 + Mini WDO - no controls 4385 101 AP100 + Mini WDO - incl level switch for 1 pp (stand-alone) 4385 102 AP100 + Mini WDO - incl control panel for 16 pp 127 Compressors Chillers Heat pumps Controls Heat exchangers Customised AfterMarketPDF Image | Sabroe Products 2022

PDF Search Title:

Sabroe Products 2022Original File Name Searched:

Sabroe_product_catalogue_2022_EN_interactive.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |