PDF Publication Title:

Text from PDF Page: 015

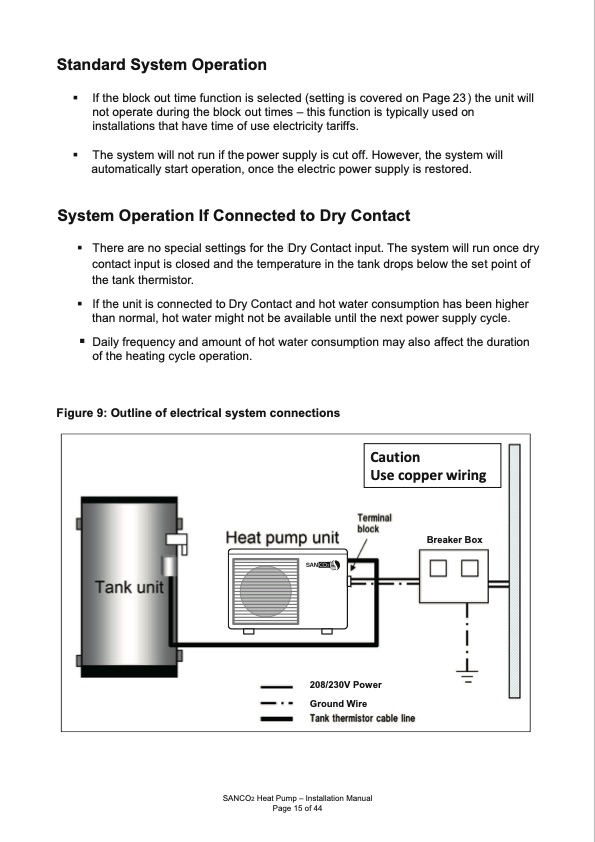

Ensure that the work site is tidy; Sanden International recommends the use of Slim Duct or Conduit System operation using continuous Power Supply System operation using continuous Power Supply If the block out time function is selected (setting is covered on Page 18) the unit will StyasntedmardopSeyrsateiomnOupsienrgatciontinuousPowerSupply not operate during the block out times – this function is typically used on If the block out time function is selected (setting is covered on Page 18) the unit will installations that have time of use electricity tariffs. not operate during the block out times – this function is typically used on If the block out time function is selected (setting is covered on Page 21328) the unit will installations that have time of use electricity tariffs. not operate during the block out times – this function is typically used on The water heating cycle operation starts automatically when the residual hot water installations that have time of use electricity tariffs. in the tank unit is less than 40 gallons (150 litres). The water heating cycle operation starts automatically when the residual hot water in the tank unit is less than 40 gallons (150 litres). The water heating cycle oper The system will not run if the will automatically start operation, once the electric power supply is restored. tem The system will not run if the electrical power supply is cut off. However, the system System operation if connected to Demand Response Power will automatically start operation, once the electric power supply is restored. System oOperrattiioniIffcCoonnneeccteteddtotoDDermyaCnodnRtaecstponse Power There are no special settings for the Demand Response. The system will run once System operation if connected to Demand Response Power power becomes available and the tem There are no special settings for the of the tank thermistor. of the tank thermistor. the tank thermistor. pbreoevnidheisghaemr tihnaimnunmoromfa5l,h If cthoennuencittinsgcothneneucntiet dtotoD ation starts automatically when the residual hot water peolewcetrricsaulppolyweisrcsutpopflfy.Hisocwuetvoeffr.,Hthoewseyvseter,mthweisllystem in the tank unit is less than 40 gallons (150 litres). awuiltloamuatotimcaltlyicastllayrtsotapret roaptieorna,tionc, eonthce ethlecetrlieccptroicwpeor wsuepr psluypipslryeistoreresdto.red. The system will not run if the electrical power supply is cut off. However, the sys tsoupfipllltyhceytcalnek. unit with hot water. If the ambient temperature is lower than 50 F (10 C) this can be longer. tsoupfipllltyhceytcalnek. unit with hot water. perature in the tank drops below the set point DerymCaonndtaRcetsipnopnust.eT.hTehesysytestmemwiwllirllurnunonocnecedry power becomes available and the temperature in the tank drops below the set point contact input is closed and the temperature in the tank drops below the set point of There are no special settings for the Demand Response. The system will run once of the tank thermistor. power becomes available and the temperature in the tank drops below the set point I I f f c t h o e n n u e n c i t t i i n s g c o t h n e n e u c n t i e t d t o t o D e D me ma n a d n d R e R s e p s o p n o s n e s e p o p w o e w r e e r n a s n u d r e h o t h t a w t a t h t e e r p c o o wn s e u r ms u p p t i p o l n y h a s houtrwsactoenrtminiugohutsnpotowbera,vaasilaitbcleanutnatkilethaet nleeaxsttpfouwrehrours eDmreymaCnadonndRtaeRcsetpsaopnodsnehseoptopwoaewtreernacsonundrsehuotmhtapwtaitohtnerhpcaoswnbseeuremsnupphtipoiglnyhehras tpbhreaoenvnidnheoisgrmhaeamrl,tihnoaimtnwunmaotreomrfam5l,ihghohoutrnwsoacttobenertmianvuigaohiultasnbpoletowbuenetrai,lvtahaseilaitnbcelaexntuptnaotkiwleteharetsnlueepaxpstltypfocyuwcrelhero. urs oo If connecting the unit to Demand Response power ensure that the power supply provides a minimum of 5 hours continuous power, as it can take at least four hours Daily frequency and amount of hot water consumpo tion may also affect the duration If the ambient temperature is lower than 50 F (10 C) this can be longer. to fill the tank unit with hot water. of the heating cycle operation. Daily frequency and amount of hot water consumption may also affect the duration Figure 9: Outline of electrical system connections Figure 9: Outline of electrical system connections Sanden Heat Pump – Installation Manual oo If the ambient temperature is lowePragthea1n3 o5f040F (10 C) this can be longer. of the heating cycle operation. Sanden Heat Pump – Installation Manual Page 13 of 40 Sanden Heat Pump – Installation Manual Page 13 of 40 Caution C U pper wiring a s e c u t io n o Use copper wiring Breaker Box Breaker Box 208/230V Power 20 8 / 2 3 0V P o G r wer o u n d W ir e Ground Wire The basic system installation is now complete; the unit is nTohwe braesaidcysfyosrtienmitiianlswtaltleartifoilnlinisgn, aoiwr pcuormgeplaented;thenusntiatritsup CnohwecrkeathdeyIfnosrtainlliatitaiol nwatgearinfislltintgh,eaIinrsptaulrlgaetioandChtheecnkslitsatrt up SANCO2 Heat Pump – Installation Manual Page 15 of 44 pCrhoevcikdethdeatIntshtealelantdioonf athgiasinmsat nthuealInstallation Check list provided at the end of this manualPDF Image | SANCO2 Heat Pump Water Heater R744

PDF Search Title:

SANCO2 Heat Pump Water Heater R744Original File Name Searched:

Installation_Manual_SANCO2.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |