PDF Publication Title:

Text from PDF Page: 004

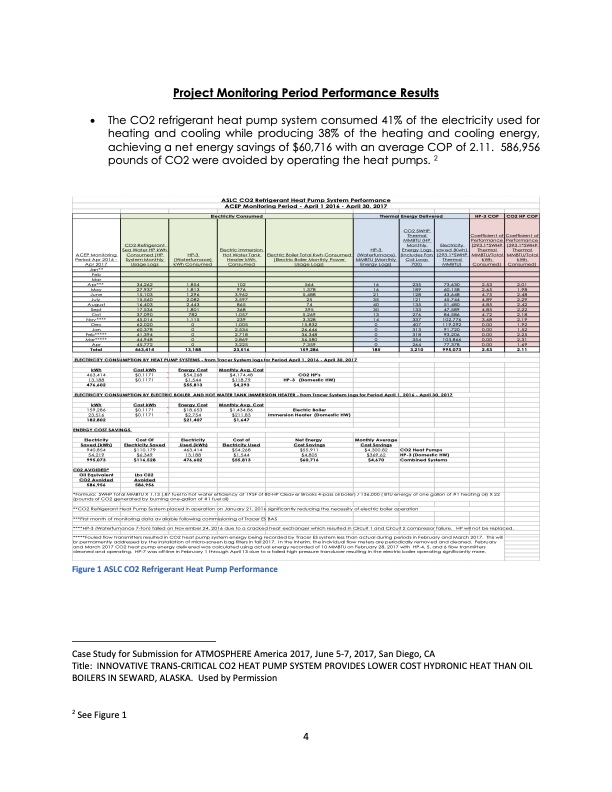

Project Monitoring Period Performance Results • The CO2 refrigerant heat pump system consumed 41% of the electricity used for heating and cooling while producing 38% of the heating and cooling energy, achieving a net energy savings of $60,716 with an average COP of 2.11. 586,956 pounds of CO2 were avoided by operating the heat pumps. 2 ASLC CO2 Refrigerant Heat Pump System Performance ACEP Monitoring Period - April 1 2016 - April 30, 2017 Electricity Consumed Thermal Energy Delivered HP-3 COP CO2 HP COP ACEP Monitoring CO2 Refrigerant Sea Water HP kWh HP-3 (Waterfurnace) kWh Consumed Electric Immersion Electric Boiler Total Kwh Consumed HP-3 (Waterfurnace) CO2 SWHP Thermal MMBTU (HP Monthly Energy Logs Electricity saved (Kwh) Coefficient of Coefficient of Performance Performance (293.1*SWHP (293.1*SWHP Thermal MMBTU/Total Thermal MMBTU/Total Consumed (HP System Monthly Usage Logs Hot Water Tank Heater kWh Consumed (Includes Fan (293.1*SWHP Period Apr 2016 - (Electric Boiler Monthly Power Usage Logs) MMBTU (Monthly Coil Loop 700) Thermal MMBTU) kWh Consumed) kWh Consumed) Apr 2017 Energy Logs) Jan** Feb Mar Apr*** 34,262 1,854 102 564 16 235 73,630 2.53 2.01 May 27,937 1,813 976 1,378 16 189 60,158 2.65 1.98 June 15,103 1,296 3,962 5,488 21 128 43,648 4.75 2.48 July 15,560 2,082 3,597 25 35 121 45,744 4.89 2.29 August 16,403 2,443 865 74 40 135 51,480 4.85 2.42 Sept 17,534 1,801 368 395 30 133 47,589 4.85 2.22 Oct 37,090 782 1,057 5,269 13 276 84,586 4.72 2.18 Nov **** 45,014 1,115 239 3,328 14 337 102,776 3.68 2.19 Dec 62,020 0 1,005 15,832 0 407 119,292 0.00 1.92 Jan 60,378 0 2,534 26,646 0 313 91,720 0.00 1.52 Feb***** 41,394 0 2,718 36,348 0 318 93,206 0.00 2.25 Mar***** 44,948 0 2,869 56,580 0 354 103,866 0.00 2.31 Apr 45,772 0 3,225 7,359 0 264 77,378 0.00 1.69 Total 463,414 13,188 23,516 159,286 185 3,210 995,073 2.53 2.11 ELECTRICITY CONSUMPTION BY HEAT PUMP SYSTEMS - from Tracer System logs for Period April 1, 2016 - April 30, 2017 kWh Cost kWh Energy Cost Monthly Avg. Cost 463,414 $0.1171 $54,268 $4,174.48 CO2 HP's 13,188 $0.1171 $1,544 $118.79 HP-3 (Domestic HW) 476,602 $55,813 $4,293 ELECTRICITY CONSUMPTION BY ELECTRIC BOILER AND HOT WATER TANK IMMERSION HEATER - from Tracer System logs for Period April 1, 2016 - April 30, 2017 kWh Cost kWh Energy Cost Monthly Avg. Cost 159,286 $0.1171 $18,653 $1,434.86 Electric Boiler 23,516 $0.1171 $2,754 $211.83 Immersion Heater (Domestic HW) 182,802 $21,407 $1,647 ENERGY COST SAVINGS Electricity Cost Of Electricity Cost of Net Energy Monthly Average Saved (kWh) Electricity Saved Used (kWh) Electricity Used Cost Savings Cost Savings 940,854 $110,179 463,414 $54,268 $55,911 $4,300.82 CO2 Heat Pumps 54,219 $6,349 13,188 $1,544 $4,805 $369.62 HP-3 (Domestic HW) 995,073 $116,528 476,602 $55,813 $60,716 $4,670 Combined Systems C02 AVOIDED* Oil Equivalent Lbs C02 CO2 Avoided Avoided 586,956 586,956 *Formula: SWHP Total MMBTU X 1.13 (.87 fuel to hot water efficiency at 195F of 80-HP Cleav er Brooks 4-pass oil boiler) / 136,000 ( BTU energy of one gallon of #1 heating oil) X 22 (pounds of CO2 generated by burning one-gallon of #1 fuel oil) **CO2 Refrigerant Heat Pump System placed in operation on January 21, 2016 significantly reducing the necessity of electric boiler operation ***First month of monitoring data available following commissioning of Tracer ES BAS ****HP-3 (Waterfurnance 7-Ton) failed on Nov ember 24, 2016 due to a cracked heat exchanger which resulted in Circuit 1 and Circuit 2 compressor failure. HP will not be replaced. *****Fouled flow transmitters resulted in CO2 heat pump system energy being recorded by Tracer ES system less than actual during periods in February and March 2017. This will br permamently addressed by the installation of micro-screen bag filters in fall 2017. In the interim, the indv idual flow meters are periodically remov ed and cleaned. February and March 2017 CO2 heat pump energy deliv ered was calculated using actual energy recorded of 10 MMBTU on February 28, 2017 with HP-4, 5, and 6 flow tranmitters cleaned and operating. HP-7 was off-line in February 1 through April 13 due to a failed high pressure tranducer resulting in the electric boiler operating significantly more. Figure 1 ASLC CO2 Refrigerant Heat Pump Performance Case Study for Submission for ATMOSPHERE America 2017, June 5-7, 2017, San Diego, CA Title: INNOVATIVE TRANS-CRITICAL CO2 HEAT PUMP SYSTEM PROVIDES LOWER COST HYDRONIC HEAT THAN OIL BOILERS IN SEWARD, ALASKA. Used by Permission 2 See Figure 1 4PDF Image | Trans-Critical CO2 Heat Pump System AEA Grant

PDF Search Title:

Trans-Critical CO2 Heat Pump System AEA GrantOriginal File Name Searched:

CO2_Heat_Pump_Systems_Final.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |