PDF Publication Title:

Text from PDF Page: 008

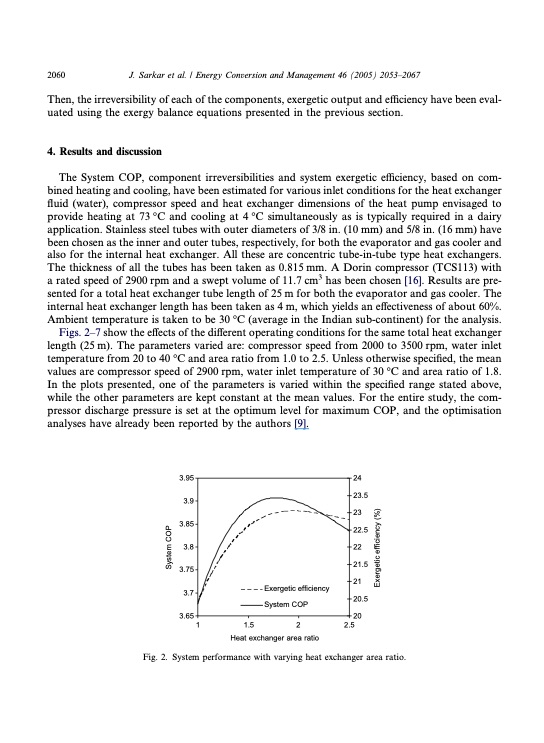

2060 J. Sarkar et al. / Energy Conversion and Management 46 (2005) 2053–2067 Then, the irreversibility of each of the components, exergetic output and efficiency have been eval- uated using the exergy balance equations presented in the previous section. 4. Results and discussion The System COP, component irreversibilities and system exergetic efficiency, based on com- bined heating and cooling, have been estimated for various inlet conditions for the heat exchanger fluid (water), compressor speed and heat exchanger dimensions of the heat pump envisaged to provide heating at 73 °C and cooling at 4 °C simultaneously as is typically required in a dairy application. Stainless steel tubes with outer diameters of 3/8 in. (10 mm) and 5/8 in. (16 mm) have been chosen as the inner and outer tubes, respectively, for both the evaporator and gas cooler and also for the internal heat exchanger. All these are concentric tube-in-tube type heat exchangers. The thickness of all the tubes has been taken as 0.815 mm. A Dorin compressor (TCS113) with a rated speed of 2900 rpm and a swept volume of 11.7 cm3 has been chosen [16]. Results are pre- sented for a total heat exchanger tube length of 25 m for both the evaporator and gas cooler. The internal heat exchanger length has been taken as 4 m, which yields an effectiveness of about 60%. Ambient temperature is taken to be 30 °C (average in the Indian sub-continent) for the analysis. Figs. 2–7 show the effects of the different operating conditions for the same total heat exchanger length (25 m). The parameters varied are: compressor speed from 2000 to 3500 rpm, water inlet temperature from 20 to 40 °C and area ratio from 1.0 to 2.5. Unless otherwise specified, the mean values are compressor speed of 2900 rpm, water inlet temperature of 30 °C and area ratio of 1.8. In the plots presented, one of the parameters is varied within the specified range stated above, while the other parameters are kept constant at the mean values. For the entire study, the com- pressor discharge pressure is set at the optimum level for maximum COP, and the optimisation analyses have already been reported by the authors [9]. 3.95 24 Exergetic efficiency System COP 3.9 3.85 23.5 23 22.5 3.8 22 3.75 3.7 21.5 21 20.5 3.65 20 1 1.5 2 2.5 Heat exchanger area ratio Fig. 2. System performance with varying heat exchanger area ratio. System COP Exergetic efficiency (%)PDF Image | Transcritical CO2 heat pump systems

PDF Search Title:

Transcritical CO2 heat pump systemsOriginal File Name Searched:

Transcritical-CO2-heat-pump-systems.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |