PDF Publication Title:

Text from PDF Page: 005

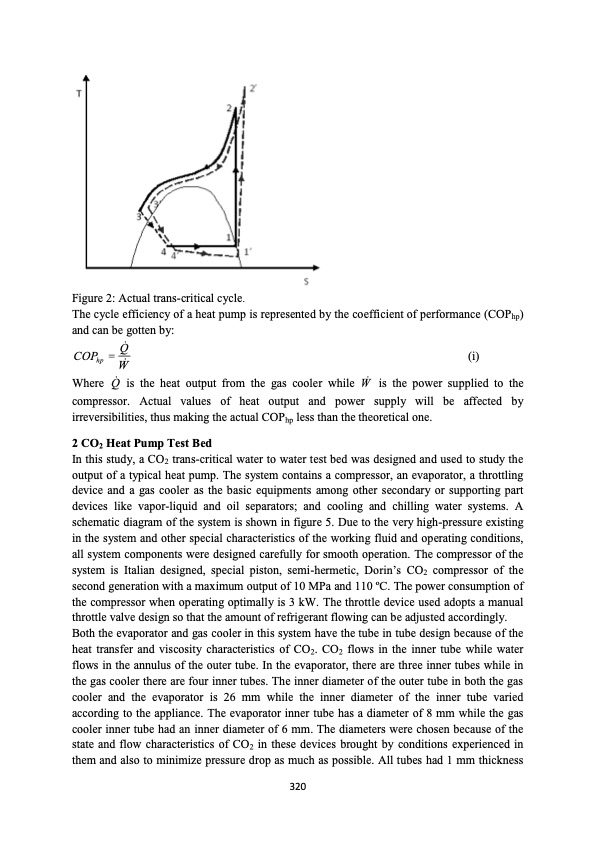

Figure 2: Actual trans-critical cycle. The cycle efficiency of a heat pump is represented by the coefficient of performance (COPhp) and can be gotten by: W Where Q is the heat output from the gas cooler while W is the power supplied to the compressor. Actual values of heat output and power supply will be affected by irreversibilities, thus making the actual COPhp less than the theoretical one. 2 CO2 Heat Pump Test Bed In this study, a CO2 trans-critical water to water test bed was designed and used to study the output of a typical heat pump. The system contains a compressor, an evaporator, a throttling device and a gas cooler as the basic equipments among other secondary or supporting part devices like vapor-liquid and oil separators; and cooling and chilling water systems. A schematic diagram of the system is shown in figure 5. Due to the very high-pressure existing in the system and other special characteristics of the working fluid and operating conditions, all system components were designed carefully for smooth operation. The compressor of the system is Italian designed, special piston, semi-hermetic, Dorin’s CO2 compressor of the second generation with a maximum output of 10 MPa and 110 oC. The power consumption of the compressor when operating optimally is 3 kW. The throttle device used adopts a manual throttle valve design so that the amount of refrigerant flowing can be adjusted accordingly. Both the evaporator and gas cooler in this system have the tube in tube design because of the heat transfer and viscosity characteristics of CO2. CO2 flows in the inner tube while water flows in the annulus of the outer tube. In the evaporator, there are three inner tubes while in the gas cooler there are four inner tubes. The inner diameter of the outer tube in both the gas cooler and the evaporator is 26 mm while the inner diameter of the inner tube varied according to the appliance. The evaporator inner tube has a diameter of 8 mm while the gas cooler inner tube had an inner diameter of 6 mm. The diameters were chosen because of the state and flow characteristics of CO2 in these devices brought by conditions experienced in them and also to minimize pressure drop as much as possible. All tubes had 1 mm thickness COP Q (i) hp 320PDF Image | TYPICAL INITIAL OUTPUT OF A CO2 HEAT PUMP

PDF Search Title:

TYPICAL INITIAL OUTPUT OF A CO2 HEAT PUMPOriginal File Name Searched:

paper_extended_length_energy_paper.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |