PDF Publication Title:

Text from PDF Page: 006

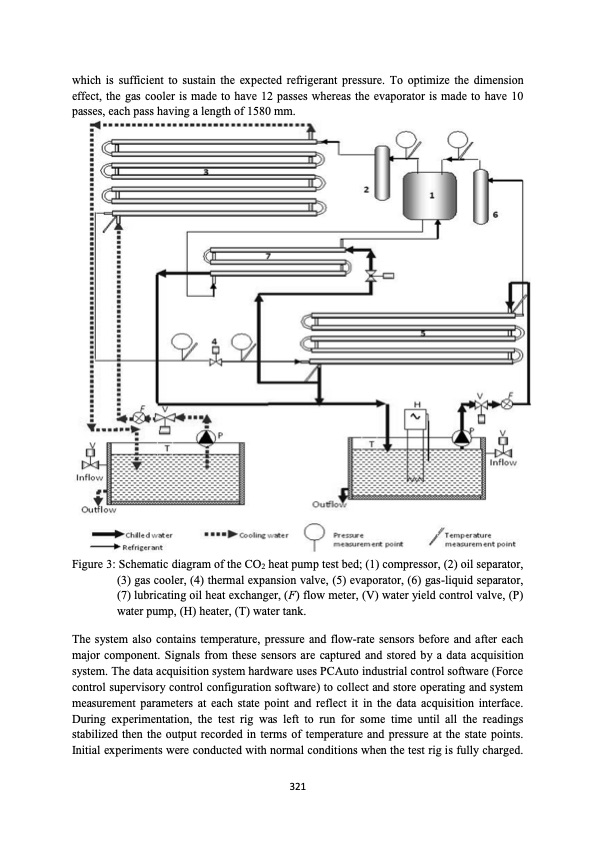

which is sufficient to sustain the expected refrigerant pressure. To optimize the dimension effect, the gas cooler is made to have 12 passes whereas the evaporator is made to have 10 passes, each pass having a length of 1580 mm. Figure 3: Schematic diagram of the CO2 heat pump test bed; (1) compressor, (2) oil separator, (3) gas cooler, (4) thermal expansion valve, (5) evaporator, (6) gas-liquid separator, (7) lubricating oil heat exchanger, (F) flow meter, (V) water yield control valve, (P) water pump, (H) heater, (T) water tank. The system also contains temperature, pressure and flow-rate sensors before and after each major component. Signals from these sensors are captured and stored by a data acquisition system. The data acquisition system hardware uses PCAuto industrial control software (Force control supervisory control configuration software) to collect and store operating and system measurement parameters at each state point and reflect it in the data acquisition interface. During experimentation, the test rig was left to run for some time until all the readings stabilized then the output recorded in terms of temperature and pressure at the state points. Initial experiments were conducted with normal conditions when the test rig is fully charged. 321PDF Image | TYPICAL INITIAL OUTPUT OF A CO2 HEAT PUMP

PDF Search Title:

TYPICAL INITIAL OUTPUT OF A CO2 HEAT PUMPOriginal File Name Searched:

paper_extended_length_energy_paper.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |