PDF Publication Title:

Text from PDF Page: 003

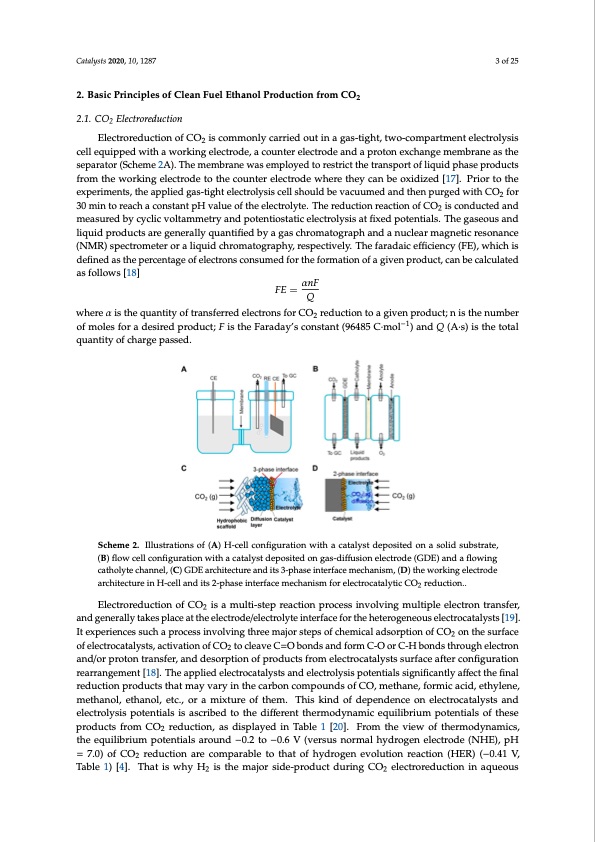

Catalysts 2020, 10, 1287 3 of 25 2. Basic Principles of Clean Fuel Ethanol Production from CO2 Catalysts 2020, 10, x FOR PEER REVIEW 3 of 25 2.1. CO2 Electroreduction ElectroreductionofCO2 iscommonlycarriedoutinagas-tight,two-compartmentelectrolysis 2 cell equipped with a working electrode, a counter electrode and a proton exchange membrane as the separator(S(Scchheemee2A2A).)T.hTehmeemebmrabnreawneaswemaspelomypedlotyoerdestoricrtetshterictrtanthsepotrtaonfslpiqourtidopfhlaiqsueipdropdhuacstes fprroomdutchteswfromrkitnhgeweleocrtkriondgeetloecthroedceotuonthereecloeucntrtoedrelwechtreordeethwehyecraenthbeeyocxaindibzedox[i1d7i]z.edPr[i1o7r].toPrtihoer etoxpthereimexepnetrsi,mtheenatsp,pthliedapgpasli-etidghgtase-lteicgthrotleylseicstcroellyshisocuelldl sbheovualcdubuemveadcuanudmtehdenanpdurtghedn wpuitrhgeCdOwfitohr 2 3C0Om2 ifnorto3r0eamchinatcoonresatacnhtapHcovnasltuaentofptHhevealelucterolfyteh.eTehlecrterdoulyctieo.nTrheeacrteiodnucotfioCnOreiascctoionnduocfteCdOa2nids 2 mcoenadsucrteedbayncdycmliecavsoulrteadmbmyetcryclaicndvoplotatemnmtioestrtaytiacnedlepctortoelnytsiiossatat tfiicxedlepctortoelnytsiaslsa.t Tfihxedgapseooteunstiaanlsd. lTiqhueigdapsreoduuscatns darleiqgueinderparlolyduquctasnatirfieegdebnyeralglyasqcuharnotmifaietdogbryapahgaansdcahrnoumclaetaorgmraapghneatnicdraesnouncalnecaer (mNaMgnRe)tiscpercetsronmanetcer (oNr Ma lRiq)usipdechtromeateorgroarpahyl,iqreusipdecthirvoemly.atTohgerafparhayd,ariecsepffiectiievnecly.(FTEh)e, wfahraicdhaics defeffiicniendcays(tFhEe)p,werhceicnhtaigsedoefienledctraosntshceopnesrucmenetdagfoerotfhelefocrtrmoantsiocnonosfuamgeivdefnoprrtohdeufoctr,mcantiobnecoaflacugliavtedn apsrofodlulocwt,sca[n18b]ecalculatedasfollows[18] αnF FE = = Q where α is the quantity of transferred electrons for CO2 reduction to a given product; n is the number where α is the quantity of transferred electrons for CO2 reduction to a give−n1product; n is the number of moles for a desired product; F is the Faraday’s constant (96485 C·mol ) and Q (A·s) is the total of moles for a desired product; F is the Faraday’s constant (96485 C·mol−1) and Q (A·s) is the total quantity of charge passed. quantity of charge passed. Scheme 2. Illustrations of (A) H-cell configuration with a catalyst deposited on a solid substrate, Scheme 2. Illustrations of (A) H-cell configuration with a catalyst deposited on a solid substrate, (B) (B) flow cell configuration with a catalyst deposited on gas-diffusion electrode (GDE) and a flowing flow cell configuration with a catalyst deposited on gas-diffusion electrode (GDE) and a flowing catholyte channel, (C) GDE architecture and its 3-phase interface mechanism, (D) the working electrode catholyte channel, (C) GDE architecture and its 3-phase interface mechanism, (D) the working architecture in H-cell and its 2-phase interface mechanism for electrocatalytic CO2 reduction.. electrode architecture in H-cell and its 2-phase interface mechanism for electrocatalytic CO2 reduction.. Electroreduction of CO2 is a multi-step reaction process involving multiple electron transfer, and generally takes place at the electrode/electrolyte interface for the heterogeneous electrocatalysts [19]. Electroreduction of CO2 is a multi-step reaction process involving multiple electron transfer, It experiences such a process involving three major steps of chemical adsorption of CO2 on the surface and generally takes place at the electrode/electrolyte interface for the heterogeneous electrocatalysts of electrocatalysts, activation of CO2 to cleave C=O bonds and form C-O or C-H bonds through electron [19]. It experiences such a process involving three major steps of chemical adsorption of CO2 on the and/or proton transfer, and desorption of products from electrocatalysts surface after configuration surface of electrocatalysts, activation of CO2 to cleave C=O bonds and form C-O or C-H bonds rearrangement [18]. The applied electrocatalysts and electrolysis potentials significantly affect the final through electron and/or proton transfer, and desorption of products from electrocatalysts surface reduction products that may vary in the carbon compounds of CO, methane, formic acid, ethylene, after configuration rearrangement [18]. The applied electrocatalysts and electrolysis potentials methanol, ethanol, etc., or a mixture of them. This kind of dependence on electrocatalysts and significantly affect the final reduction products that may vary in the carbon compounds of CO, electrolysis potentials is ascribed to the different thermodynamic equilibrium potentials of these methane, formic acid, ethylene, methanol, ethanol, etc., or a mixture of them. This kind of products from CO2 reduction, as displayed in Table 1 [20]. From the view of thermodynamics, dependence on electrocatalysts and electrolysis potentials is ascribed to the different the equilibrium potentials around −0.2 to −0.6 V (versus normal hydrogen electrode (NHE), pH thermodynamic equilibrium potentials of these products from CO2 reduction, as displayed in Table = 7.0) of CO2 reduction are comparable to that of hydrogen evolution reaction (HER) (−0.41 V, 1 [20]. From the view of thermodynamics, the equilibrium potentials around −0.2 to −0.6 V (versus Table 1) [4]. That is why H2 is the major side-product during CO2 electroreduction in aqueous normal hydrogen electrode (NHE), pH = 7.0) of CO2 reduction are comparable to that of hydrogen evolution reaction (HER) (−0.41 V, Table 1) [4]. That is why H2 is the major side-product during CO2 electroreduction in aqueous electrolytes. Additionally, the very small differences between the thermodynamic potentials for CO2 reduction products bring about a challenge to selectively produce the desirable carbon compounds. Actually, the required potentials to drive CO2 reductions are morePDF Image | Advances in Clean Fuel Ethanol Production from CO2 Reduction

PDF Search Title:

Advances in Clean Fuel Ethanol Production from CO2 ReductionOriginal File Name Searched:

catalysts-10-01287.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |