PDF Publication Title:

Text from PDF Page: 002

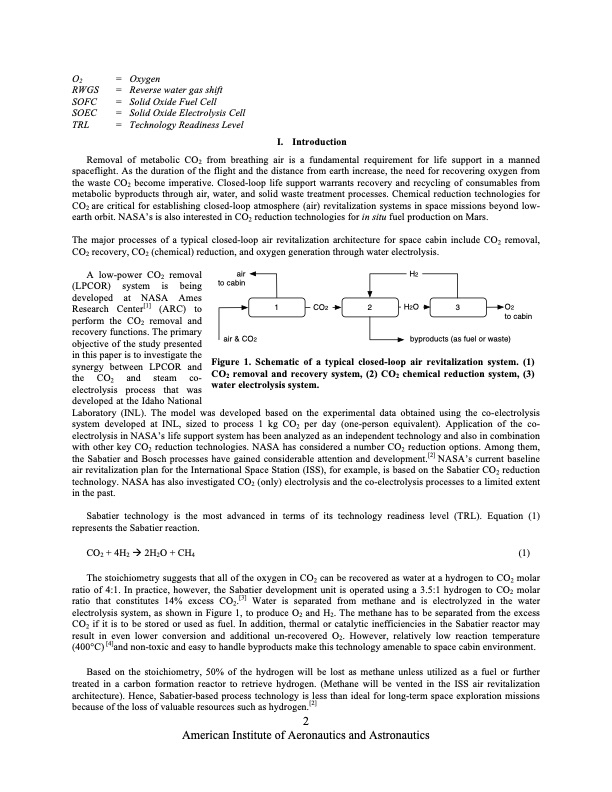

O2 = RWGS = SOFC = SOEC = TRL = Oxygen Reverse water gas shift Solid Oxide Fuel Cell Solid Oxide Electrolysis Cell Technology Readiness Level I. Introduction Removal of metabolic CO2 from breathing air is a fundamental requirement for life support in a manned spaceflight. As the duration of the flight and the distance from earth increase, the need for recovering oxygen from the waste CO2 become imperative. Closed-loop life support warrants recovery and recycling of consumables from metabolic byproducts through air, water, and solid waste treatment processes. Chemical reduction technologies for CO2 are critical for establishing closed-loop atmosphere (air) revitalization systems in space missions beyond low- earth orbit. NASA’s is also interested in CO2 reduction technologies for in situ fuel production on Mars. The major processes of a typical closed-loop air revitalization architecture for space cabin include CO2 removal, CO2 recovery, CO2 (chemical) reduction, and oxygen generation through water electrolysis. A low-power CO2 removal (LPCOR) system is being developed at NASA Ames Research Center[1] (ARC) to perform the CO2 removal and recovery functions. The primary objective of the study presented in this paper is to investigate the synergy between LPCOR and the CO2 and steam co- electrolysis process that was developed at the Idaho National Laboratory (INL). The model was developed based on the experimental data obtained using the co-electrolysis system developed at INL, sized to process 1 kg CO2 per day (one-person equivalent). Application of the co- electrolysis in NASA’s life support system has been analyzed as an independent technology and also in combination with other key CO2 reduction technologies. NASA has considered a number CO2 reduction options. Among them, the Sabatier and Bosch processes have gained considerable attention and development.[2] NASA’s current baseline air revitalization plan for the International Space Station (ISS), for example, is based on the Sabatier CO2 reduction technology. NASA has also investigated CO2 (only) electrolysis and the co-electrolysis processes to a limited extent in the past. Sabatier technology is the most advanced in terms of its technology readiness level (TRL). Equation (1) represents the Sabatier reaction. CO2 + 4H22H2O + CH4 (1) The stoichiometry suggests that all of the oxygen in CO2 can be recovered as water at a hydrogen to CO2 molar ratio of 4:1. In practice, however, the Sabatier development unit is operated using a 3.5:1 hydrogen to CO2 molar ratio that constitutes 14% excess CO2.[3] Water is separated from methane and is electrolyzed in the water electrolysis system, as shown in Figure 1, to produce O2 and H2. The methane has to be separated from the excess CO2 if it is to be stored or used as fuel. In addition, thermal or catalytic inefficiencies in the Sabatier reactor may result in even lower conversion and additional un-recovered O2. However, relatively low reaction temperature (400°C) [4]and non-toxic and easy to handle byproducts make this technology amenable to space cabin environment. Based on the stoichiometry, 50% of the hydrogen will be lost as methane unless utilized as a fuel or further treated in a carbon formation reactor to retrieve hydrogen. (Methane will be vented in the ISS air revitalization architecture). Hence, Sabatier-based process technology is less than ideal for long-term space exploration missions because of the loss of valuable resources such as hydrogen.[2] 2 American Institute of Aeronautics and Astronautics air to cabin H2 byproducts (as fuel or waste) air & CO2 1 CO2 2 H2O 3 O2 to cabin Figure 1. Schematic of a typical closed-loop air revitalization system. (1) CO2 removal and recovery system, (2) CO2 chemical reduction system, (3) water electrolysis system.PDF Image | CO2 and Steam Co-Electrolysis for Resource Utilization in Space

PDF Search Title:

CO2 and Steam Co-Electrolysis for Resource Utilization in SpaceOriginal File Name Searched:

20100039170.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |