PDF Publication Title:

Text from PDF Page: 039

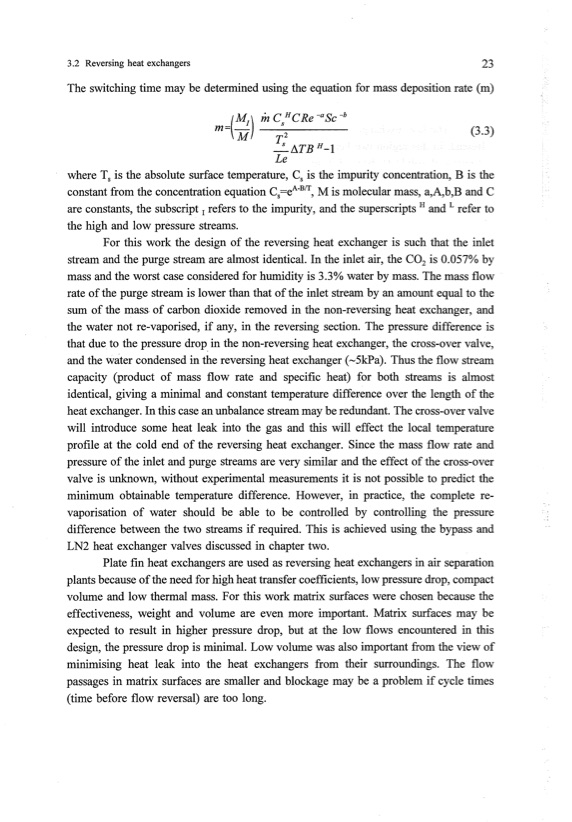

3.2 Reversing heat exchangers 23 The switching time may be determined using the equation for mass deposition rate (m) Qb m=(~) _in_~_s:_C_R_e_-_s,_c_-_ _ s IlTB H-l Le (3.3) where Ts is the absolute surface temperature, Cs is the impurity concentration, B is the constant from the concentration equation Cs=eA-Brr, M is molecular mass, a,A,b,B and C are constants, the subscript I refers to the impurity, and the superscripts Hand L refer to the high and low pressure streams. For this work the design of the reversing heat exchanger is such that the inlet stream and the purge stream are almost identical. In the inlet air, the CO2 is 0.057% by mass and the worst case considered for humidity is 3.3% water by mass. The mass flow rate of the purge stream is lower than that of the inlet stream by an amount equal to the sum of the mass of carbon dioxide removed in the non-reversing heat exchanger, and the water not re-vaporised, if any, in the reversing section. The pressure difference is that due to the pressure drop in the non-reversing heat exchanger, the cross-over valve, and the water condensed in the reversing heat exchanger (~5kPa). Thus the flow stream capacity (product of mass flow rate and specific heat) for both streams is almost identical, giving a minimal and constant temperature difference over the length of the heat exchanger. In this case an unbalance stream may be redundant. The cross-over valve will introduce some heat leak into the gas and this will effect the local temperature profile at the cold end of the reversing heat exchanger. Since the mass flow rate and pressure of the inlet and purge streams are very similar and the effect of the cross-over valve is unknown, without experimental measurements it is not possible to predict the minimum obtainable temperature difference. However, in practice, the complete re- vaporisation of water should be able to be controlled by controlling the pressure difference between the two streams if required. This is achieved using the bypass and LN2 heat exchanger valves discussed in chapter two. Plate fin heat exchangers are used as reversing heat exchangers in air separation plants because o f the need for high heat transfer coefficients, low pressure drop, compact volume and low thermal mass. For this work matrix surfaces were chosen because the effectiveness, weight and volume are even more important. Matrix surfaces may be expected to result in higher pressure drop, but at the low flows encountered in this design, the pressure drop is minimal. Low volume was also important from the view of minimising heat leak into the heat exchangers from their surroundings. The flow passages in matrix surfaces are smaller and blockage may be a problem if cycle times (time before flow reversal) are too long.PDF Image | CO2 removal from air for alkaline fuel cells operating with liquid H2

PDF Search Title:

CO2 removal from air for alkaline fuel cells operating with liquid H2Original File Name Searched:

35465756.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |