PDF Publication Title:

Text from PDF Page: 003

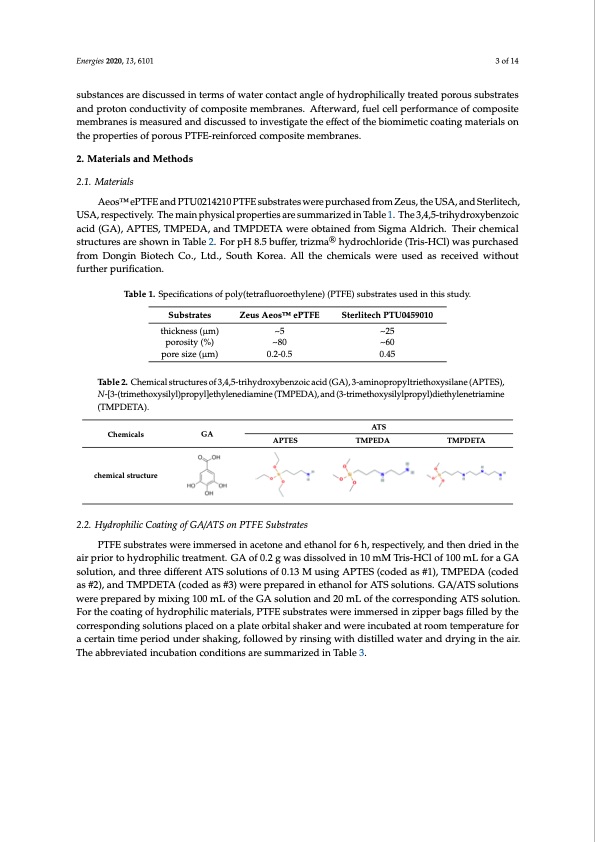

materials on the properties of porous PTFE-reinforced composite membranes. e m e y composite membranes is measured and discussed to investigate the effect of the biomimetic coating materials on the properties of porous PTFE-reinforced composite membranes. 2. Materials and Methods 2.1. Materials 2.1. Materials AeosTM ePTFE and PTU0214210 PTFE substrates were purchased from Zeus, th Energies 2020, 13, 6101 3 of 14 Sterlitech, USA, respectively. The main physical properties are summarized in Table 1 AeosTM ePTFE and PTUt0r2ih1y4d2r1o0xyPbTeFnEzoiscuabcsidtr(aGteAs),wAePrTeESp,uTrMchPaEsDeAd, farnodmTMZPeDusE,TtAheweUreSAob,tainded from Sig 2. Materials and Methods Sterlitech, USA, respectively.Thheeir mchaeimnicpahl ystsriuccatlurpersoaprersthieoswanriensTuamblem2a.rFizoredpHin8.T5abbulfefe1r,.tTrihzme a3,4h,5y-drochlorid Energies 2020, 13, x FOR PEER REVIEW 3 of 14 substances are discussedtrinihytedrmoxsyboefnwzoaictearcicdo(nGtAac),twAaaPnsTgpElueSr,cohTfaMshePdyEdfDrorAomp, DahnoidnligcTinaMlBlPiyoDtteErceThaACtoew.d,eLrptedo.o,rbSotoauitsnhesKduofbresoatm.rAaSltliegtshmeachAelmdirciaclhs.were used without further purification. and protosunbsctorantedsuancdtivpriotytoTnohcfeoicrnodchmuectmpivoictsyailtoesftrcmuomcetmuporebsistrearmneesmsh.borwAanfetsien.rAwTfataebrlweda2,r.fdFu,oefrulepclHecel8ll.p5pebruffofofremrrma,ntracienzmocfeaohfycdormocphlosritde (Tris-HCl) composite membranwesais pmueracshuaresdedanfdrodmiscDuossnegdintoBiniovteesctihgaCteo.t,hLetedff.,ecStooufttheKboiroemai.mAeltlicthceoacthinegmicals were used as received membranes is measured and discussed to investigate the effect of the biomimetic coating materials on Table 1. Specifications of poly(tetrafluoroethylene) (PTFE) substrates used in this stud Energies 2020, 13, x FOR PEER REVIEW 3 of 14 materials on the properties of porous PTFE-reinforced composite membranes. without further purification. Substrates substrates and proton con2d. MucattievriitaylsoafncdoMmeptohsoidtes membranes. Afterward, fuel cell performance of the properties of porous PTFE-reinforced composite membranes. Zeus AeosTM ePTFE Sterlitech PTU0459010 Table 1. Specifications of poly(tetrafluoroethylene) (PTFE) substrates used in this study. composite mem2b.raMneasteisrmiaelassaunred Manedtdhioscdussed to investigate the effect of the biomimetic coating thickness (m) ~5 ~25 2.1. Materials Zeus Sterlitech materials on the properties of porous PTFE-reinforced composite membranes. porosity (%) ~80 ~60 2.1. MaterialsAeos 2. Materials and Methods 2.1. Materials Aeos was purchased from Dongin Biotech Co., Ltd., South Korea. All the chemicals were used as received Substrates AeosTM ePpToFreEsizPeT(Um0)459010.2‒0.5 0.45 ePTFE and PTU0214210 PTFE substrates were purchased from Zeus, the USA, and TM Sterlitech, USA, respectively. The main physical properties are summarized in Table 1. The 3,4,5- thickness (m) ~5 ~25 AeosTM ePTFE and PTU0214210 PTFE substrates werTeapblue r2c. ChhaesmeidcalfsrtorumctuZreesuofs3,,t4h,5e-trUihySdAro,xaybnednzSoitcearcliidte(GcAh), 3-aminopropyltriethoxy trihydroxybenzoic acid (GA), APTES, TMPEDA, anpdoTrMosPiDtyE(T%A)were obtai~n8e0d from Sigma A~l6d0rich. (APTES), N-[3-(trimethoxysilyl)propyl]ethylenediamine (TMPEDA), and (3- Their chemical structures are shown in Table 2. For pH 8.5 buffer, trizma hydrochloride (Tris-HCl) USA, respectively. The main physical properties aproerseusmizem(amriz) ed in T0.a2b‒l0e.51. The 3,4,05.4-t5rihydroxybenzoic trimethoxysilylpropyl)diethylenetriamine (TMPDETA). acid (GA), APTES, TMPEDA, and TMPDETA were obtained from Sigma Aldrich. Their chemical ePTFE and PTU0214210 PTFE substrates were purchased from Zeus, the USA, and TM Sterlitech,USAs,trreuspcetuctriveeslya.reThsehomwainipnhyTsaibcallep2r.oFpeorrtipesHar8e.5submumffaeri,zterdizimnTaablhey1d.rTohceh3l,o4r,5id-e(Tris-HCl)waspurchased without further purification. Table 2. Chemical structures of 3,4,5-trihydroxybenzoic acid (GA), 3-aminopropyltriethoxysilane ® (APTES), N-[3-(trimethoxysilyl)propyl]ethylenediamine (TMPEDA), and (3- trihydroxybenzoic acid (GA), APTETSa,bTleM1P. SEpDecAifi,catniodnsToMf pPoDly(EteTtrAaflwuoerroetohbylteanien)e(PdTfFrEo)msubSsitgramteas uAsledriincth.is study. from Dongin Biotech Co., Ltd., South Korea. All the chemicals were used as received without trimethoxysilylpropyl)diethylenetriamine (TMPDETA). Their chemical structures are shown in Table 2. For pH 8.5 buffer, trizma hydrochloride (Tris-HCl) further purification. Substrates Zeus Sterlitech was purchased from Dongin Biotech Co., Ltd., South Korea. All the chemicals were used as received without further purification. AeosTM ePTFE PTU0459010 thickness (m) ~5 ~25 Table 1. Specifications of poly(tetrafluoroethylene) (PTFE) substrates used in this study. porosity (%) ~80 ~60 Table 1. Specifications of poly(tetrafluoroethylene) (PTFE) substrates used in this study. pore size (m) 0.2‒0.5 0.45 Substrates Zeus AeosTM ePTFE Sterlitech PTU0459010 Zeus Sterlitech SubTsatbrlaet2et.shCihcekmniceaslst(rμucmtu)res of 3,4,5-trihydro~x5ybenzoic acid (GA), 3-aminoprop~y2ltr5iethoxysilane AeosTM ePTFE PTU0459010 (APTES), N-[3-(trimethoxysilyl)propyl]ethylenediamine (TMPEDA), and (3- porosity (%) ~80 ~60 thickness (m) ~5 ~25 trimethoxysilylpropyl)diethylenetriamine (TMPDETA). pore size (m) 0.2‒0.5 0.45 Table 2. Chemical structures of 3,4,5-trihydroxybenzoic acid (GA), 3-aminopropyltriethoxysilane (APTES), Table 2. ChemicNal-s[t3r-u(ctrtuimreestohfo3x,4y,5si-ltyrilh)ypdroropxylb]enthzyoilcenaceidi(aGmAi)n,e3-(aTmMinPoEpDroApy),ltarniedth(o3x-tyrsiimlaentehoxysilylpropyl)diethylenetriamine (APTES), N-[3-(trimethoxysilyl)propyl]ethylenediamine (TMPEDA), and (3- pore size (μm) 0.2-0.5 porosity (%) ~80 ~60 0.45 (TMPDETA). trimethoxysilylpropyl)diethylenetriamine (TMPDETA). Chemicals GA chemical structure APTES ATS TMPEDA TMPDETA 2.2. Hydrophilic Coating of GA/ATS on PTFE Substrates PTFE substrates were immersed in acetone and ethanol for 6 h, respectively, and then dried in the air prior to hydrophilic treatment. GA of 0.2 g was dissolved in 10 mM Tris-HCl of 100 mL for a GA solution, and three different ATS solutions of 0.13 M using APTES (coded as #1), TMPEDA (coded as #2), and TMPDETA (coded as #3) were prepared in ethanol for ATS solutions. GA/ATS solutions were prepared by mixing 100 mL of the GA solution and 20 mL of the corresponding ATS solution. For the coating of hydrophilic materials, PTFE substrates were immersed in zipper bags filled by the corresponding solutions placed on a plate orbital shaker and were incubated at room temperature for a certain time period under shaking, followed by rinsing with distilled water and drying in the air. The abbreviated incubation conditions are summarized in Table 3.PDF Image | Composite Membranes Using Hydrophilized Porous Substrates

PDF Search Title:

Composite Membranes Using Hydrophilized Porous SubstratesOriginal File Name Searched:

energies-13-06101.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |