PDF Publication Title:

Text from PDF Page: 004

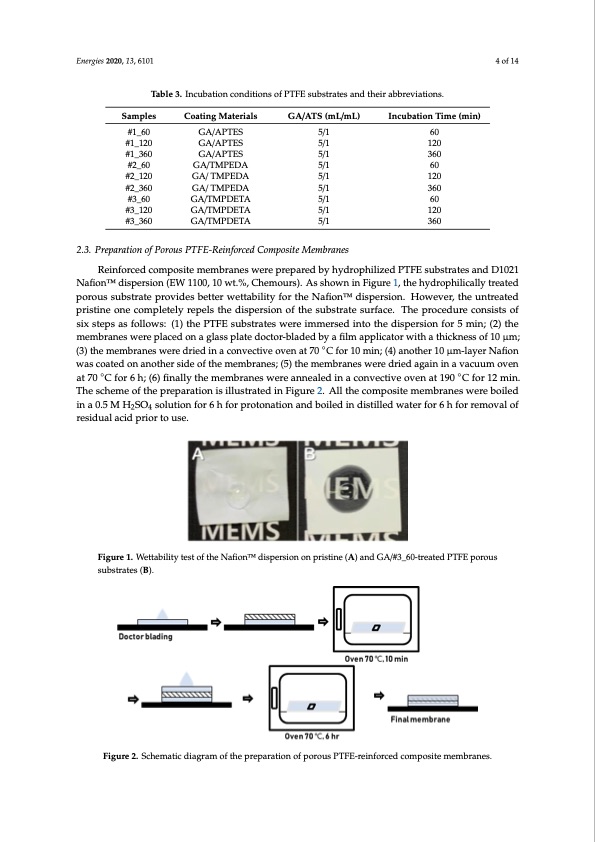

were prepared by mixing 100 mL of the GA solution and 20 mL of the corresponding ATS solution. For the coating of hydrophilic materials, PTFE substrates were immersed in zipper bags filled by the corresponding solutions placed on a plate orbital shaker and were incubated at room temperature for a certain time period under shaking, followed by rinsing with distilled water and drying in the air. The abbreviated incubation conditions are summarized in Table 3. Energies 2020, 13, 6101 Table 3. Incubation conditions of PTFE substrates and their abbreviations. Table 3. Incubation conditions of PTFE substrates and their abbreviations. Samples Coating Materials 4 of 14 GA/ ATS (mL/mL) Incubation Time (min) Samples #1_60 #1_120 #1_360 #2_60 #2_120 #2_360 #3_60 #3_120 #3_360 Coating Materials #1_60 GA/APTES GA/ATS (mL/mL) 5/1 Incubation Time (min) GA/APTES #1_120 GA/APTES 60 5/1 120 5/1 360 GA/APTES #1_360 GA/APTES 5/1 60 5/1 120 GA/APTES GA/TMPEDA 5/1 360 5/1 60 #2_60 #2_120 #2_360 #3_60 #3_120 GA/TMGPAD/ETTMAPDETA #3_360 GA/TMGPAD/ETTMAPDETA GA/TMPEDA GA/ TMPEDA 5/1 60 5/1 120 GA/ TMPEDA GA/ TMPEDA 5/1 120 5/1 360 GA/ TMPEDA GA/TMPDETA 5/1 360 5/1 60 GA/TMPDETA 5/1 60 5//1 120 120 5//1 360 360 2.3. Preparation of Porous PTFE-Reinforced Composite Membranes 2.3. Preparation of Porous PTFE-Reinforced Composite Membranes Reinforced composite membranes were prepared by hydrophilized PTFE substrates and D1021 Reinforced composite membranes were prepared by hydrophilized PTFE substrates and D1021 NafionTM dispersion (EW 1100, 10 wt.%, Chemours). As shown in Figure 1, the hydrophilically treated NafionTM dispersion (EW 1100, 10 wt.%, Chemours). As shown in Figure 1, the hydrophilically treated porous substrate provides better wettability for the NafionTM dispersion. However, the untreated porous substrate provides better wettability for the NafionTM dispersion. However, the untreated pristine one completely repels the dispersion of the substrate surface. The procedure consists of six pristine one completely repels the dispersion of the substrate surface. The procedure consists of steps as follows: (1) the PTFE substrates were immersed into the dispersion for 5 min; (2) the six steps as follows: (1) the PTFE substrates were immersed into the dispersion for 5 min; (2) the membranes were placed on a glass plate doctor-bladed by a film applicator with a thickness of 10 membranes were placed on a glass plate doctor-bladed by a film applicator with a thickness of 10 μm; m; (3) the membranes were dried in a convective oven ◦at 70 °C for 10 min; (4) another 10 m-layer (3) the membranes were dried in a convective oven at 70 C for 10 min; (4) another 10 μm-layer Nafion Nafion was coated on another side of the membranes; (5) the membranes were dried again in a was coated on another side of the membranes; (5) the membranes were dried again in a vacuum oven vacuum◦ oven at 70 °C for 6 h; (6) finally the membranes were annealed in a convective◦ oven at 190 at 70 C for 6 h; (6) finally the membranes were annealed in a convective oven at 190 C for 12 min. °C for 12 min. The scheme of the preparation is illustrated in Figure 2. All the composite membranes The scheme of the preparation is illustrated in Figure 2. All the composite membranes were boiled were boiled in a 0.5 M H2SO4 solution for 6 h for protonation and boiled in distilled water for 6 h for in a 0.5 M H2SO4 solution for 6 h for protonation and boiled in distilled water for 6 h for removal of removal of residual acid prior to use. residual acid prior to use. Energies 2020, 13, x FOR PEER REVIEW 5 of 14 Figure 1. Wettability test of the NafionTM dispersion on pristine (A) and GA/#3_60-treated PTFE Figure 1. Wettability test of the NafionTM dispersion on pristine (A) and GA/#3_60-treated PTFE porous porous substrates (B). substrates (B). Figure 2. Schematic diagram of the preparation of porous PTFE-reinforced composite membranes. Figure 2. Schematic diagram of the preparation of porous PTFE-reinforced composite membranes. 2.4. Characterization of Material Structure and GA/ATS Solutions Measurement of contact angle of PTFE substrates with and without hydrophilic material coating was carried out using a contact angle meter (Attension Theta Lite, Bioline Scientific, Sweden) as soon as a droplet of the Nafion dispersion falls on substrates. Microcosmic morphology of thePDF Image | Composite Membranes Using Hydrophilized Porous Substrates

PDF Search Title:

Composite Membranes Using Hydrophilized Porous SubstratesOriginal File Name Searched:

energies-13-06101.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |