PDF Publication Title:

Text from PDF Page: 003

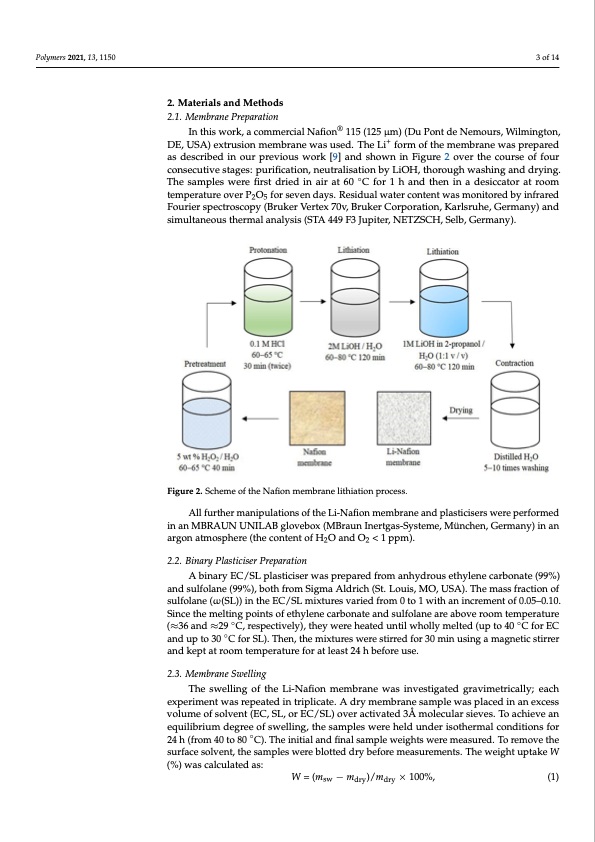

Polymers 2021, 13, 1150 amorphous structure was observed. These results provide an insight into the physico- chemical nature of Li-Nafion membranes swollen with aprotic solvents. 2. Materials and Methods 3 of 14 2.1. Membrane Preparation In this work, a commercial Nafion® 115 (125 μm) (Du Pont de Nemours, Wilmington, 2. Materials and Methods DE, USA) extrusion membrane was used. The Li+ form of the membrane was prepared as 2.1. Membrane Preparation described in our previous work [9] and shown in Figure 2 over the course of four consec- In this work, a commercial Nafion® 115 (125 μm) (Du Pont de Nemours, Wilmington, utive stages: purification, neutralisation by LiOH, thorough washing and drying. The DE, USA) extrusion membrane was used. The Li+ form of the membrane was prepared samples were first dried in air at 60 °C for 1 h and then in a desiccator at room temperature as described in our previous work [9] and shown in Figure 2 over the course of four over P2O5 for seven days. Residual water content was monitored by infrared Fourier spec- consecutive stages: purification, neutralisation by LiOH, thorough washing and drying. troscopy (Bruker Vertex 70v, Bruker Corporation, Karlsruhe, Germany) and simultaneous The samples were first dried in air at 60 ◦C for 1 h and then in a desiccator at room thermal analysis (STA 449 F3 Jupiter, NETZSCH, Selb, Germany). temperatureoverPO forsevendays.Residualwatercontentwasmonitoredbyinfrared 25 All further manipulations of the Li-Nafion membrane and plasticisers were per- Fourier spectroscopy (Bruker Vertex 70v, Bruker Corporation, Karlsruhe, Germany) and formed in an MBRAUN UNILAB glovebox (MBraun Inertgas-Systeme, München, Ger- simultaneous thermal analysis (STA 449 F3 Jupiter, NETZSCH, Selb, Germany). many) in an argon atmosphere (the content of H2O and O2 < 1 ppm). FFigiguurere22..ScShchememeeooffththeeNNafaifioonnmmemembbraranneeliltihthiaiatitoionnpprorocecesss.. All further manipulations of the Li-Nafion membrane and plasticisers were performed 2.2. Binary Plasticiser Preparation in an MBRAUN UNILAB glovebox (MBraun Inertgas-Systeme, München, Germany) in an A binary EC/SL plasticiser was prepared from anhydrous ethylene carbonate (99%) argon atmosphere (the content of H2O and O2 < 1 ppm). and sulfolane (99%), both from Sigma Aldrich (St. Louis, MO, USA)). The mass fraction of sulfolane (ω(SL)) in the EC/SL mixtures varied from 0 to 1 with an increment of 0.05–0.10. 2.2. Binary Plasticiser Preparation Since the melting points of ethylene carbonate and sulfolane are above room temperature A binary EC/SL plasticiser was prepared from anhydrous ethylene carbonate (99%) (≈36 and ≈29 °C, respectively), they were heated until wholly melted (up to 40 °C for EC and sulfolane (99%), both from Sigma Aldrich (St. Louis, MO, USA). The mass fraction of and up to 30 °C for SL). Then, the mixtures were stirred for 30 min using a magnetic stirrer sulfolane (ω(SL)) in the EC/SL mixtures varied from 0 to 1 with an increment of 0.05–0.10. and kept at room temperature for at least 24 h before use. Since the melting points of ethylene carbonate and sulfolane are above room temperature (≈36 and ≈29 ◦C, respectively), they were heated until wholly melted (up to 40 ◦C for EC 2.3. Membrane Swelling and up to 30 ◦C for SL). Then, the mixtures were stirred for 30 min using a magnetic stirrer The swelling of the Li-Nafion membrane was investigated gravimetrically; each ex- and kept at room temperature for at least 24 h before use. periment was repeated in triplicate. A dry membrane sample was placed in an excess vol- u2m.3e.oMfesmolbvreante(SEwCe,llSinLg,orEC/SL)overactivated3Åmolecularsieves.Toachieveanequi- librium degree of swelling, the samples were held under isothermal conditions for 24 h The swelling of the Li-Nafion membrane was investigated gravimetrically; each (from 40 to 80 °C). The initial and final sample weights were measured. To remove the experiment was repeated in triplicate. A dry membrane sample was placed in an excess volume of solvent (EC, SL, or EC/SL) over activated 3Å molecular sieves. To achieve an equilibrium degree of swelling, the samples were held under isothermal conditions for 24 h (from 40 to 80 ◦C). The initial and final sample weights were measured. To remove the surface solvent, the samples were blotted dry before measurements. The weight uptake W (%) was calculated as: W = (msw − mdry)/mdry × 100%, (1)PDF Image | Li-Nafion Membrane Plasticised with Ethylene Carbonate Sulfolane

PDF Search Title:

Li-Nafion Membrane Plasticised with Ethylene Carbonate SulfolaneOriginal File Name Searched:

polymers-13-01150.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |