PDF Publication Title:

Text from PDF Page: 005

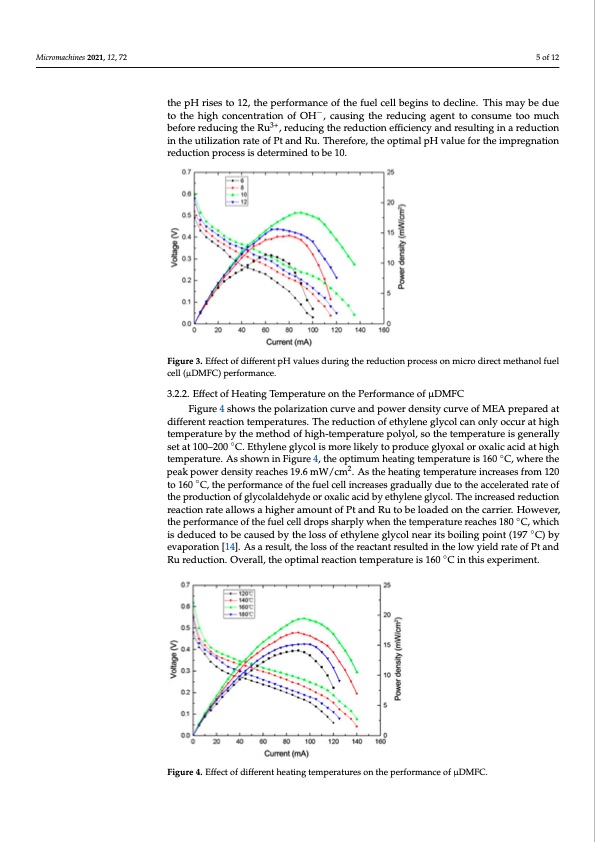

Micromachines 2021, 12, 72 fuel cell are considerably low (0.5 V), reaching the peak power density of 12 mW/cm2 at 60 mA. At pH 8, when the environment changed from weak acid to weak alkaline, the performance of the whole fuel cell improved significantly, reaching the peak power den- sity of 14 mW/cm2. When pH = 10, the OCV and maximum power density of the fuel cell were the highest, reaching 0.6 V and 18 mW/cm2, respectively. From the data, we can de- 5 of 12 duce that a higher concentration of OH− in the solution is suitable for the reduction reac- tion process, which allows for the full reduction of Pt and Ru; the best electrocatalytic performance for the electrooxidation of methanol can be obtained at pH value of 10. When Micromachines 2021, 12, x t1o2016t0o 1C60, t°hCe, ptheerfpoermrfoarnmceanocfethoef tfhuelfucellcienlclrienacsresasgersadgruadlluyadllyuedtuoetthoetahcecaelcecrealeterdateradte of 6 of 13 the pH rises to 12, the performance of the fuel cell begins to decline. This may be due to the pH rises to 12, the performance of the fuel cell begins to decline. This may be due the high concentration of OH−, caus−ing the reducing agent to consume too much before to the high concentration of OH , causing the reducing agent to consume too much reducing the Ru3+, reduc3i+ng the reduction efficiency and resulting in a reduction in the before reducing the Ru , reducing the reduction efficiency and resulting in a reduction utilization rate of Pt and Ru. Therefore, the optimal pH value for the impregnation reduc- in the utilization rate of Pt and Ru. Therefore, the optimal pH value for the impregnation tion process is determined to be 10. reduction process is determined to be 10. Figure 3. Effect of different pH values during the reduction process on micro direct methanol fuel Figure 3. Effect of different pH values during the reduction process on micro direct methanol fuel cell(μμDMFC)perrfforrmaannccee.. 3.2.2. Effect of Heating Temperature on the Performance of μDMFC 3.2.2. Effect of Heating Temperature on the Performance of μDMFC Figure 4 shows the polarization curve and power density curve of MEA prepared at Figure 4 shows the polarization curve and power density curve of MEA prepared at different reaction temperatures. The reduction of ethylene glycol can only occur at high different reaction temperatures. The reduction of ethylene glycol can only occur at high temperature by the method of high-temperature polyol, so the temperature is generally temperature by the method of high-temperature polyol, so the temperature is generally ◦ set at 100–200°C..EEththyylelenneeglgylcyocloilsims moroerleikleiklyeltyotporopdroudceucgelygolxyaolxoarloxraolixcalcicidaactidhiagthhigh ◦ temperature. As shown in Figure 4, the optimum heating temperaturre is 160 °C,, where the 2 ptheeakpepaokwpeorwderndseitnysirteyacrehaecsh1e9s.619m.6Wm/Wcm/cm. A. Assththeehheeaatitninggtteemperrattureincreases from 120 ◦ 2 trhaeteporfodthuecptiroondoufctgiloyncolfagldlyechoyldaledoehryodxealoicraocxiadlibcyaceitdhyblyeneethgyllyecnoel.gTlyhceoiln. Tcrheeasinedcrereadseudction readcutciotinonrarteeacatlilonwrsataehailglohwesramhioguhnertoamfPotuanntdofRPutatondbeRluoatodebdelonadthedeocanrtrhier.caHrroiwer.ever, However, the performance of the fuel cell drops sharply when the temperature reaches the performance of the fuel cell drops sharply when the temperature reaches 180 C, which 180 °C, which is deduced to be caused by the loss of ethylene glycol near its boiling point is deduced to be caused by the loss of ethylene glycol near its boiling point (197 C) by (197 °C) by evaporation [14]. As a result, the loss of the reactant resulted in the low yield evaporation [14]. As a result, the loss of the reactant resulted in the low yield rate of Pt and rate of Pt and Ru reduction. Overall, the optimal reaction temperature is 160 °C in this Ru reduction. Overall, the optimal reaction temperature is 160 ◦C in this experiment. experiment. ◦ ◦ Figure 4. EffecttoffdififfeerreenntthheeaatitninggtetmempepreartautruerseosnotnhethpeeprfeorfmoramncaenocfeμoDf μMDFMC.FC. 3.2.3. The Effect of Heating Time on the Performance of μDMFC Figure 5 depicts the I-V and I-P curves of μDMFC with different heating times in the catalyst preparation process. The cell with the heating time of 6 h exhibits the best perfor- mance when the pH and the heating temperature are set at 10 and 160 °C, respectively. ItPDF Image | Micro Direct Methanol Fuel Cell Reduced Graphene Oxide

PDF Search Title:

Micro Direct Methanol Fuel Cell Reduced Graphene OxideOriginal File Name Searched:

micromachines-12-00072-v2.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |