PDF Publication Title:

Text from PDF Page: 007

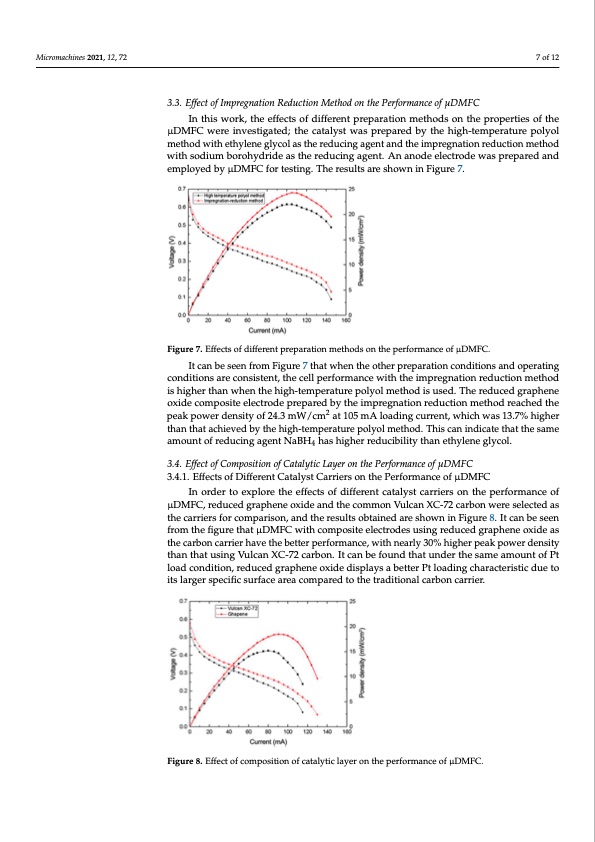

Micromachines 2021, 12, 72 7 of 12 Micromachines 2021, 12, x 2 thanthatachiieveedbythehiigh--tteemppeerartauturereppoloyloylomlmetehtohdo.dT.hTishicsacnaninidnicdaitceatehathtathtethesame Figure 6. Performance curve of μDMFC prepared under optimal process parameters. 3.3. Effect of Impregnation Reduction Method on the Performance of μDMFC 3.3. Effect of Impregnation Reduction Method on the Performance of μDMFC IIntthhisiswworokr,kt,hteheffefcftescotsfdoifffdeirfefnetrepnretpareaptiaornamtioenthomdestohnodthseopnrothpertpiersopoefrtthiesofthe μμDMFCweerereinivnevsetisgtaigteadte;dth;ethcaetaclaytsatlywsatswparespparedpabryedthbeyhitghhe-themigphe-rtaetmurpeepraotlyuorlepolyol method with ethylene glycol as the reducing agent and the impregnation reduction method with ethylene glycol as the reducing agent and the impregnation reduction method method with sodium borohydride as the reducing agent. An anode electrode was pre- with sodium borohydride as the reducing agent. An anode electrode was prepared and pared and employed by μDMFC for testing. The results are shown in Figure 7. employed by μDMFC for testing. The results are shown in Figure 7. Figure 7. Effects of different preparation methods on the performance of μDMFC. Figure 7. Effects of different preparation methods on the performance of μDMFC. It can be seen from Figure 7 that when the other preparation conditions and operating It can be seen from Figure 7 that when the other preparation conditions and operating conditions are consistent, the cell performance with the impregnation reduction method conditions are consistent, the cell performance with the impregnation reduction method is higher than when the high-temperature polyol method is used. The reduced graphene is higher than when the high-temperature polyol method is used. The reduced graphene oxide composite electrode prepared by the impregnation reduction method reached the oxide composite electrode prepared by the impregnation reduction method reached the 2 peakpoweerrddenensistyityofo2f42.34.m3Wm/Wcm/camt10a5tm10A5lmoaAdinlogacduirnrgenctu,rwrehnicth,whasic1h3.w7%ash1ig3h.7e%r higher saamoeuanmtoufnrteodfurceidnugcainggeangteNntaNBHaBHh4ahsahsihgihgehrereredduucciibiilliitythanetthyylelenneeglgylcyoclo.l. 4 3.4. Effect of Composition of Catalytic Layer on the Performance of μDMFC 3.4. Effect of Composition of Catalytic Layer on the Performance of μDMFC 3.4.1. Effects of Different Catalyst Carriers on the Performance of μDMFC 3.4.1. Effects of Different Catalyst Carriers on the Performance of μDMFC In order to explore the effects of different catalyst carriers on the performance of In order to explore the effects of different catalyst carriers on the performance of μDMFC, reduced graphene oxide and the common Vulcan XC-72 carbon were selected as μDMFC, reduced graphene oxide and the common Vulcan XC-72 carbon were selected as the carriers for comparison, and the results obtained are shown in Figure 8. It can be seen the carriers for comparison, and the results obtained are shown in Figure 8. It can be seen from the figure that μDMFC with composite electrodes using reduced graphene oxide as from the figure that μDMFC with composite electrodes using reduced graphene oxide as the carbon carrier have the better performance, with nearly 30% higher peak power density the carbon carrier have the better performance, with nearly 30% higher peak power den- than that using Vulcan XC-72 carbon. It can be found that under the same amount of Pt sity than that using Vulcan XC-72 carbon. It can be found that under the same amount of load condition, reduced graphene oxide displays a better Pt loading characteristic due to Pt load condition, reduced graphene oxide displays a better Pt loading characteristic due ittosiltasrlgaergresrpsepceicfiicficsusurfrafacceeareacomparredtotoththeetrtardaidtiiotnioanlacalrcbaornbocanrrciaerr.ier. 8 of 13 Figure 8. Effect of composition of catalytic layer on the performance of μDMFC. Figure 8. Effect of composition of catalytic layer on the performance of μDMFC. 3.4.2. Effect of Pt-Ru Molar Ratio on the Performance of μDMFC In the Pt-Ru catalyst system, Ru can more easily reduce OH- in water than Pt, and it promotes the oxidation reaction of Pt intermediate products, which can effectively reduce CO adhesion on the surface of Pt due to incomplete oxidation, thereby enhancing the elec- trocatalytic performance of Pt [16]. However, excessive Ru will surround the surface of Pt particles, which will reduce the catalytic oxidation surface area of Pt particles. The influ-PDF Image | Micro Direct Methanol Fuel Cell Reduced Graphene Oxide

PDF Search Title:

Micro Direct Methanol Fuel Cell Reduced Graphene OxideOriginal File Name Searched:

micromachines-12-00072-v2.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |