PDF Publication Title:

Text from PDF Page: 003

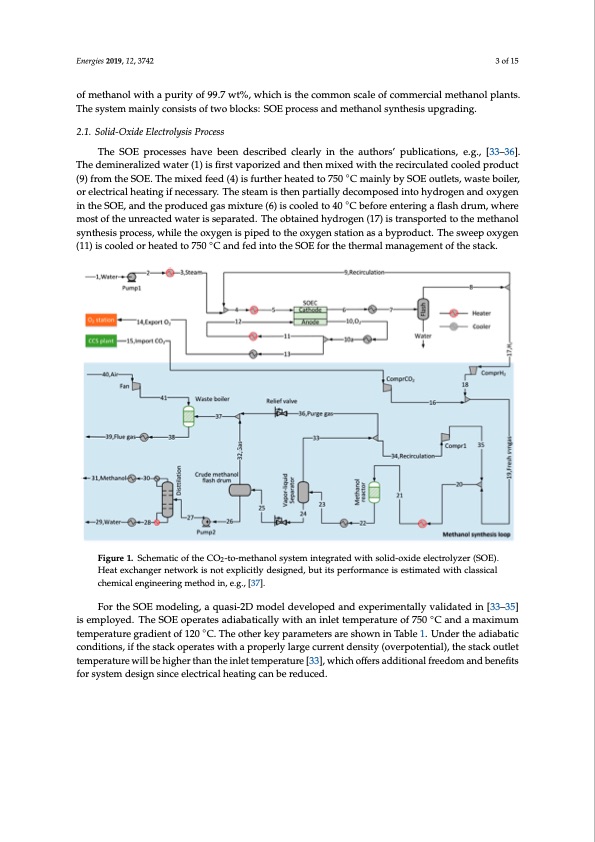

Energies 2018, 11, x FOR PEER REVIEW 3 of 15 of methanol with a purity of 99.7 wt%, which is the common scale of commercial methanol plants. The system mainly consists of two blocks: SOE process and methanol synthesis upgrading. Energies 2019, 12, 3742 3 of 15 2.1. Solid-Oxide Electrolysis Process The SOE processes have been described clearly in the authors’ publications, e.g., [33–36]. The of methanol with a purity of 99.7 wt%, which is the common scale of commercial methanol plants. demineralized water (1) is first vaporized and then mixed with the recirculated cooled product (9) The system mainly consists of two blocks: SOE process and methanol synthesis upgrading. from the SOE. The mixed feed (4) is further heated to 750 °C mainly by SOE outlets, waste boiler, or electrical heating if necessary. The steam is then partially decomposed into hydrogen and oxygen in 2.1. Solid-Oxide Electrolysis Process the SOE, and the produced gas mixture (6) is cooled to 40 °C before entering a flash drum, where most of the unreacted water is separated. The obtained hydrogen (17) is transported to the methanol The SOE processes have been described clearly in the authors’ publications, e.g., [33–36]. synthesis process, while the oxygen is piped to the oxygen station as a byproduct. The sweep oxygen The demineralized water (1) is first vaporized and then mixed with the recirculated cooled product (11) is cooled or heated to 750 °C and fed into the SOE for the thermal management of the stack. (9) from the SOE. The mixed feed (4) is further heated to 750 ◦C mainly by SOE outlets, waste boiler, For the SOE modeling, a quasi-2D model developed and experimentally validated in [33–35] is or electrical heating if necessary. The steam is then partially decomposed into hydrogen and oxygen employed. The SOE operates adiabatically with an inlet te◦mperature of 750 °C and a maximum in the SOE, and the produced gas mixture (6) is cooled to 40 C before entering a flash drum, where temperature gradient of 120 °C. The other key parameters are shown in Table 1. Under the adiabatic most of the unreacted water is separated. The obtained hydrogen (17) is transported to the methanol conditions, if the stack operates with a properly large current density (overpotential), the stack outlet synthesis process, while the oxygen is piped to the oxygen station as a byproduct. The sweep oxygen temperature will be higher t◦han the inlet temperature [33], which offers additional freedom and (11) is cooled or heated to 750 C and fed into the SOE for the thermal management of the stack. benefits for system design since electrical heating can be reduced. Figure 1. Schematic of the CO2-to-methanol system integrated with solid-oxide electrolyzer (SOE). Figure 1. Schematic of the CO2-to-methanol system integrated with solid-oxide electrolyzer (SOE). Heat exchanger network is not explicitly designed, but its performance is estimated with classical Heat exchanger network is not explicitly designed, but its performance is estimated with classical chemical engineering method in, e.g., [37]. chemical engineering method in, e.g., [37]. For the SOE modeling, a quasi-2D model developed and experimentally validated in [33–35] Table 1. The decision variables and their bounds. ◦ is employed. The SOE operates adiabatically with an inlet temperature of 750 ◦ C and a maximum Variable Lower Bound Upper Bound Unit temperature gradient of 120 C. The other key parameters are shown in Table 1. Under the adiabatic SOE operating pressure 1.1 78 bar conditions, if the stack operates with a properly large current density (overpotential), the stack outlet SOE steam utilization 0.3 0.8 - temperature will be higher than the inlet temperature [33], which offers additional freedom and benefits Steam feed flowrate 0.5 15 sccm/cm2 for system design since electrical heating can be reduced. Sweep-gas feed flowrate 0.1 36 sccm/cm2 Note: The SOE inlet temperature is set at 750 °C. The current density is calculated based on the given feed flowrates to reach given steam utilization.PDF Image | Optimization of CO2-to-Methanol with Solid-Oxide Electrolyzer

PDF Search Title:

Optimization of CO2-to-Methanol with Solid-Oxide ElectrolyzerOriginal File Name Searched:

energies-12-03742.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |