PDF Publication Title:

Text from PDF Page: 004

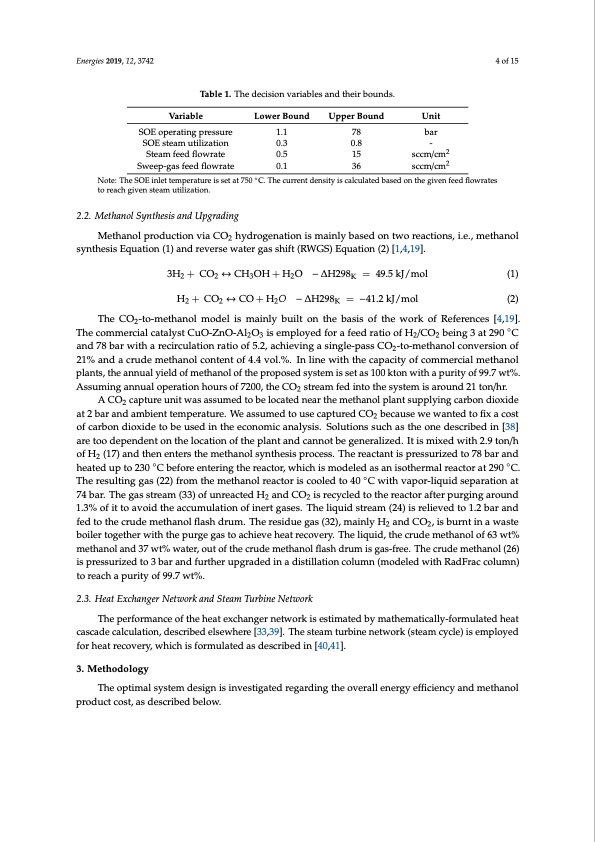

Energies 2019, 12, 3742 4 of 15 Variable SOE operating pressure SOE steam utilization Steam feed flowrate Sweep-gas feed flowrate Lower Bound 1.1 0.3 0.5 0.1 Upper Bound 78 0.8 15 36 Unit bar - sccm/cm2 sccm/cm2 Table 1. The decision variables and their bounds. Note: The SOE inlet temperature is set at 750 ◦C. The current density is calculated based on the given feed flowrates to reach given steam utilization. 2.2. Methanol Synthesis and Upgrading Methanol production via CO2 hydrogenation is mainly based on two reactions, i.e., methanol synthesis Equation (1) and reverse water gas shift (RWGS) Equation (2) [1,4,19]. 3H2 + CO2 ↔ CH3OH + H2O − ∆H298K = 49.5 kJ/mol (1) H2+ CO2 ↔CO+H2O −∆H298K = −41.2kJ/mol (2) The CO2-to-methanol model is mainly built on the basis of the work of References [4,19]. The commercial catalyst CuO-ZnO-Al2O3 is employed for a feed ratio of H2/CO2 being 3 at 290 ◦C and 78 bar with a recirculation ratio of 5.2, achieving a single-pass CO2-to-methanol conversion of 21% and a crude methanol content of 4.4 vol.%. In line with the capacity of commercial methanol plants, the annual yield of methanol of the proposed system is set as 100 kton with a purity of 99.7 wt%. Assuming annual operation hours of 7200, the CO2 stream fed into the system is around 21 ton/hr. A CO2 capture unit was assumed to be located near the methanol plant supplying carbon dioxide at 2 bar and ambient temperature. We assumed to use captured CO2 because we wanted to fix a cost of carbon dioxide to be used in the economic analysis. Solutions such as the one described in [38] are too dependent on the location of the plant and cannot be generalized. It is mixed with 2.9 ton/h of H2 (17) and then enters the methanol synthesis process. The reactant is pressurized to 78 bar and heated up to 230 ◦C before entering the reactor, which is modeled as an isothermal reactor at 290 ◦C. The resulting gas (22) from the methanol reactor is cooled to 40 ◦C with vapor-liquid separation at 74 bar. The gas stream (33) of unreacted H2 and CO2 is recycled to the reactor after purging around 1.3% of it to avoid the accumulation of inert gases. The liquid stream (24) is relieved to 1.2 bar and fed to the crude methanol flash drum. The residue gas (32), mainly H2 and CO2, is burnt in a waste boiler together with the purge gas to achieve heat recovery. The liquid, the crude methanol of 63 wt% methanol and 37 wt% water, out of the crude methanol flash drum is gas-free. The crude methanol (26) is pressurized to 3 bar and further upgraded in a distillation column (modeled with RadFrac column) to reach a purity of 99.7 wt%. 2.3. Heat Exchanger Network and Steam Turbine Network The performance of the heat exchanger network is estimated by mathematically-formulated heat cascade calculation, described elsewhere [33,39]. The steam turbine network (steam cycle) is employed for heat recovery, which is formulated as described in [40,41]. 3. Methodology The optimal system design is investigated regarding the overall energy efficiency and methanol product cost, as described below.PDF Image | Optimization of CO2-to-Methanol with Solid-Oxide Electrolyzer

PDF Search Title:

Optimization of CO2-to-Methanol with Solid-Oxide ElectrolyzerOriginal File Name Searched:

energies-12-03742.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |