PDF Publication Title:

Text from PDF Page: 002

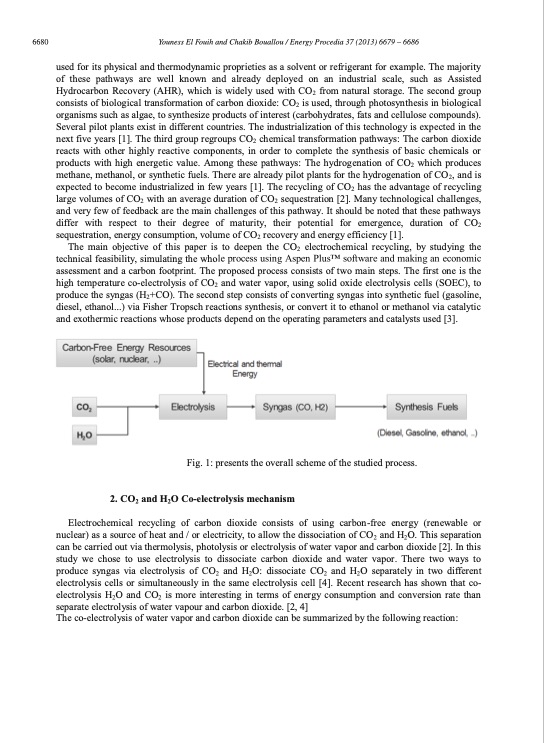

6680 Youness El Fouih and Chakib Bouallou / Energy Procedia 37 (2013) 6679 – 6686 used for its physical and thermodynamic proprieties as a solvent or refrigerant for example. The majority of these pathways are well known and already deployed on an industrial scale, such as Assisted Hydrocarbon Recovery (AHR), which is widely used with CO2 from natural storage. The second group consists of biological transformation of carbon dioxide: CO2 is used, through photosynthesis in biological organisms such as algae, to synthesize products of interest (carbohydrates, fats and cellulose compounds). Several pilot plants exist in different countries. The industrialization of this technology is expected in the next five years [1]. The third group regroups CO2 chemical transformation pathways: The carbon dioxide reacts with other highly reactive components, in order to complete the synthesis of basic chemicals or products with high energetic value. Among these pathways: The hydrogenation of CO2 which produces methane, methanol, or synthetic fuels. There are already pilot plants for the hydrogenation of CO2, and is expected to become industrialized in few years [1]. The recycling of CO2 has the advantage of recycling large volumes of CO2 with an average duration of CO2 sequestration [2]. Many technological challenges, and very few of feedback are the main challenges of this pathway. It should be noted that these pathways differ with respect to their degree of maturity, their potential for emergence, duration of CO2 sequestration, energy consumption, volume of CO2 recovery and energy efficiency [1]. The main objective of this paper is to deepen the CO2 electrochemical recycling, by studying the technical feasibility, simulating the who assessment and a carbon footprint. The proposed process consists of two main steps. The first one is the high temperature co-electrolysis of CO2 and water vapor, using solid oxide electrolysis cells (SOEC), to produce the syngas (H2+CO). The second step consists of converting syngas into synthetic fuel (gasoline, diesel, ethanol...) via Fisher Tropsch reactions synthesis, or convert it to ethanol or methanol via catalytic and exothermic reactions whose products depend on the operating parameters and catalysts used [3]. Fig. 1: presents the overall scheme of the studied process. 2. CO2 and H2O Co-electrolysis mechanism Electrochemical recycling of carbon dioxide consists of using carbon-free energy (renewable or nuclear) as a source of heat and / or electricity, to allow the dissociation of CO2 and H2O. This separation can be carried out via thermolysis, photolysis or electrolysis of water vapor and carbon dioxide [2]. In this study we chose to use electrolysis to dissociate carbon dioxide and water vapor. There two ways to produce syngas via electrolysis of CO2 and H2O: dissociate CO2 and H2O separately in two different electrolysis cells or simultaneously in the same electrolysis cell [4]. Recent research has shown that co- electrolysis H2O and CO2 is more interesting in terms of energy consumption and conversion rate than separate electrolysis of water vapour and carbon dioxide. [2, 4] The co-electrolysis of water vapor and carbon dioxide can be summarized by the following reaction:PDF Image | Recycling of carbon dioxide to produce ethanol

PDF Search Title:

Recycling of carbon dioxide to produce ethanolOriginal File Name Searched:

recycling-of-carbon-dioxide-to-produce-ethanol.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |