PDF Publication Title:

Text from PDF Page: 001

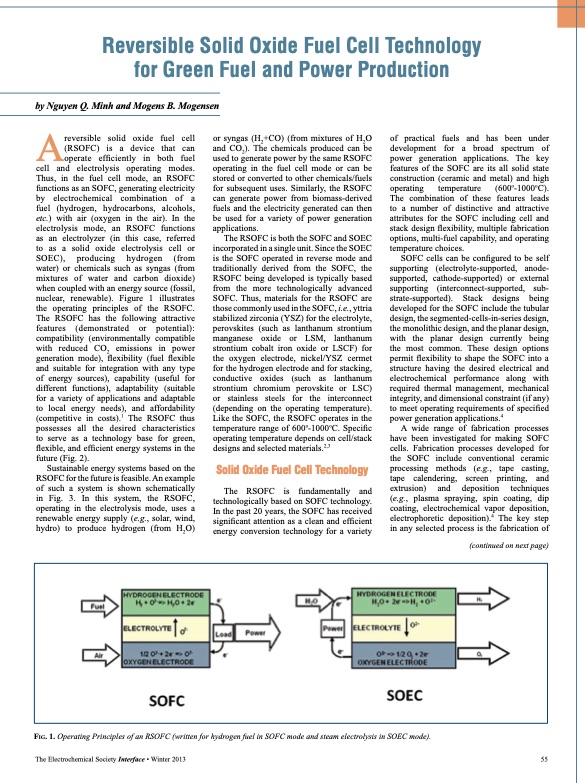

Reversible Solid Oxide Fuel Cell Technology for Green Fuel and Power Production by Nguyen Q. Minh and Mogens B. Mogensen Areversible solid oxide fuel cell (RSOFC) is a device that can operate efficiently in both fuel cell and electrolysis operating modes. Thus, in the fuel cell mode, an RSOFC functions as an SOFC, generating electricity by electrochemical combination of a fuel (hydrogen, hydrocarbons, alcohols, etc.) with air (oxygen in the air). In the electrolysis mode, an RSOFC functions as an electrolyzer (in this case, referred to as a solid oxide electrolysis cell or SOEC), producing hydrogen (from water) or chemicals such as syngas (from mixtures of water and carbon dioxide) when coupled with an energy source (fossil, nuclear, renewable). Figure 1 illustrates the operating principles of the RSOFC. The RSOFC has the following attractive features (demonstrated or potential): compatibility (environmentally compatible with reduced CO2 emissions in power generation mode), flexibility (fuel flexible and suitable for integration with any type of energy sources), capability (useful for different functions), adaptability (suitable for a variety of applications and adaptable to local energy needs), and affordability (competitive in costs).1 The RSOFC thus possesses all the desired characteristics to serve as a technology base for green, flexible, and efficient energy systems in the future (Fig. 2). Sustainable energy systems based on the RSOFC for the future is feasible. An example of such a system is shown schematically in Fig. 3. In this system, the RSOFC, operating in the electrolysis mode, uses a renewable energy supply (e.g., solar, wind, hydro) to produce hydrogen (from H2O) or syngas (H2+CO) (from mixtures of H2O and CO2). The chemicals produced can be used to generate power by the same RSOFC operating in the fuel cell mode or can be stored or converted to other chemicals/fuels for subsequent uses. Similarly, the RSOFC can generate power from biomass-derived fuels and the electricity generated can then be used for a variety of power generation applications. The RSOFC is both the SOFC and SOEC incorporated in a single unit. Since the SOEC is the SOFC operated in reverse mode and traditionally derived from the SOFC, the RSOFC being developed is typically based from the more technologically advanced SOFC. Thus, materials for the RSOFC are those commonly used in the SOFC, i.e., yttria stabilized zirconia (YSZ) for the electrolyte, perovskites (such as lanthanum strontium manganese oxide or LSM, lanthanum strontium cobalt iron oxide or LSCF) for the oxygen electrode, nickel/YSZ cermet for the hydrogen electrode and for stacking, conductive oxides (such as lanthanum strontium chromium perovskite or LSC) or stainless steels for the interconnect (depending on the operating temperature). Like the SOFC, the RSOFC operates in the temperature range of 600o-1000oC. Specific operating temperature depends on cell/stack designs and selected materials.2,3 Solid Oxide Fuel Cell Technology The RSOFC is fundamentally and technologically based on SOFC technology. In the past 20 years, the SOFC has received significant attention as a clean and efficient energy conversion technology for a variety of practical fuels and has been under development for a broad spectrum of power generation applications. The key features of the SOFC are its all solid state construction (ceramic and metal) and high operating temperature (600o-1000oC). The combination of these features leads to a number of distinctive and attractive attributes for the SOFC including cell and stack design flexibility, multiple fabrication options, multi-fuel capability, and operating temperature choices. SOFC cells can be configured to be self supporting (electrolyte-supported, anode- supported, cathode-supported) or external supporting (interconnect-supported, sub- strate-supported). Stack designs being developed for the SOFC include the tubular design, the segmented-cells-in-series design, the monolithic design, and the planar design, with the planar design currently being the most common. These design options permit flexibility to shape the SOFC into a structure having the desired electrical and electrochemical performance along with required thermal management, mechanical integrity, and dimensional constraint (if any) to meet operating requirements of specified power generation applications.4 A wide range of fabrication processes have been investigated for making SOFC cells. Fabrication processes developed for the SOFC include conventional ceramic processing methods (e.g., tape casting, tape calendering, screen printing, and extrusion) and deposition techniques (e.g., plasma spraying, spin coating, dip coating, electrochemical vapor deposition, electrophoretic deposition).4 The key step in any selected process is the fabrication of (continued on next page) Fig. 1. Operating Principles of an RSOFC (written for hydrogen fuel in SOFC mode and steam electrolysis in SOEC mode). The Electrochemical Society Interface • Winter 2013 55PDF Image | Reversible Solid Oxide Fuel Cell Technology for Green Fuel

PDF Search Title:

Reversible Solid Oxide Fuel Cell Technology for Green FuelOriginal File Name Searched:

wtr13_p055_062.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |