PDF Publication Title:

Text from PDF Page: 002

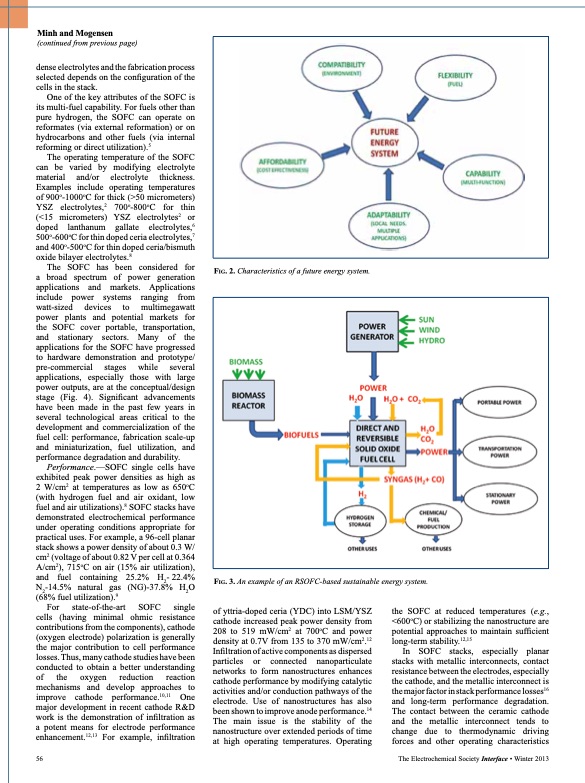

Minh and Mogensen (continued from previous page) dense electrolytes and the fabrication process selected depends on the configuration of the cells in the stack. One of the key attributes of the SOFC is its multi-fuel capability. For fuels other than pure hydrogen, the SOFC can operate on reformates (via external reformation) or on hydrocarbons and other fuels (via internal reforming or direct utilization).5 The operating temperature of the SOFC can be varied by modifying electrolyte material and/or electrolyte thickness. Examples include operating temperatures of 900o-1000oC for thick (>50 micrometers) YSZ electrolytes,2 700o-800oC for thin (<15 micrometers) YSZ electrolytes2 or doped lanthanum gallate electrolytes,6 500o-600oC for thin doped ceria electrolytes,7 and 400o-500oC for thin doped ceria/bismuth oxide bilayer electrolytes.8 The SOFC has been considered for a broad spectrum of power generation applications and markets. Applications include power systems ranging from watt-sized devices to multimegawatt power plants and potential markets for the SOFC cover portable, transportation, and stationary sectors. Many of the applications for the SOFC have progressed to hardware demonstration and prototype/ pre-commercial stages while several applications, especially those with large power outputs, are at the conceptual/design stage (Fig. 4). Significant advancements have been made in the past few years in several technological areas critical to the development and commercialization of the fuel cell: performance, fabrication scale-up and miniaturization, fuel utilization, and performance degradation and durability. Performance.—SOFC single cells have exhibited peak power densities as high as 2 W/cm2 at temperatures as low as 650oC (with hydrogen fuel and air oxidant, low fuel and air utilizations).8 SOFC stacks have demonstrated electrochemical performance under operating conditions appropriate for practical uses. For example, a 96-cell planar stack shows a power density of about 0.3 W/ cm2 (voltage of about 0.82 V per cell at 0.364 A/cm2), 715oC on air (15% air utilization), and fuel containing 25.2% H2- 22.4% N2-14.5% natural gas (NG)-37.8% H2O (68% fuel utilization).9 For state-of-the-art SOFC single cells (having minimal ohmic resistance contributions from the components), cathode (oxygen electrode) polarization is generally the major contribution to cell performance losses. Thus, many cathode studies have been conducted to obtain a better understanding of the oxygen reduction reaction mechanisms and develop approaches to improve cathode performance.10,11 One major development in recent cathode R&D work is the demonstration of infiltration as a potent means for electrode performance enhancement.12,13 For example, infiltration Fig. 2. Characteristics of a future energy system. 56 The Electrochemical Society Interface • Winter 2013 Fig. 3. An example of an RSOFC-based sustainable energy system. of yttria-doped ceria (YDC) into LSM/YSZ cathode increased peak power density from 208 to 519 mW/cm2 at 700oC and power density at 0.7V from 135 to 370 mW/cm2.12 Infiltration of active components as dispersed particles or connected nanoparticulate networks to form nanostructures enhances cathode performance by modifying catalytic activities and/or conduction pathways of the electrode. Use of nanostructures has also been shown to improve anode performance.14 The main issue is the stability of the nanostructure over extended periods of time at high operating temperatures. Operating the SOFC at reduced temperatures (e.g., <600oC) or stabilizing the nanostructure are potential approaches to maintain sufficient long-term stability.12,15 In SOFC stacks, especially planar stacks with metallic interconnects, contact resistance between the electrodes, especially the cathode, and the metallic interconnect is the major factor in stack performance losses16 and long-term performance degradation. The contact between the ceramic cathode and the metallic interconnect tends to change due to thermodynamic driving forces and other operating characteristicsPDF Image | Reversible Solid Oxide Fuel Cell Technology for Green Fuel

PDF Search Title:

Reversible Solid Oxide Fuel Cell Technology for Green FuelOriginal File Name Searched:

wtr13_p055_062.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |