PDF Publication Title:

Text from PDF Page: 003

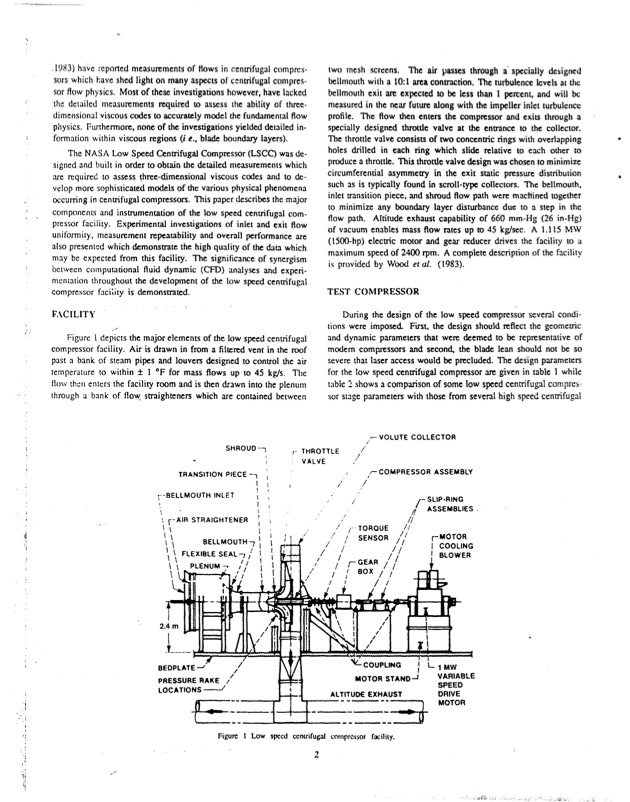

.1983) have reported measurements of flows in centrifugal compres- sors which have shed light on many aspects of centrifugal compres- sor flow physics. Most of these investigations however, have lacked the detailed measurements required to assess the ability of three- dimensional viscous codes to accurately model the fundamental flow physics. Furthermore, none of the investigations yielded detailed in- formation within viscous regions (i e.,blade boundary layers). The NASA Low Speed Centrifugal Compressor (LSCC) was de- signed and built in order to obtain the detailed measurements which are required to assess hree-dimensional viscous codes and to de- velop more sophisticated models of the various physical phenomena occurring in centrifugal compressors. This paper describes the major components and instrumentation of the low speed centrifugal corn- pressor facility. Experimental investigations of inlet and exit flow uniformity, measurement repeatability and overall performance are also presented which demonstrate the high quality of the data which may be expected from this facility. The significance of synergism between computational fluid dynamic (CFD) analyses and experi- mentation throughout the development of the low speed centrifugal compressor facility is demonstrated. FACILITY Figure Idepicts the major elements of the low speed centrifugal compressor facility. Air is drawn in from a filtered vent in the roof past a bank of steam pipes and louvers designed to control the air temperature to within ± 1 *F for mass flows up to 45 kg/s. The flow then enters the facility room and is then drawn into the plenum through a bank of flow straighteners which are contained between two mesh screens. The air passes through a'specially designed bellmouth with a 10:1 area contraction. The turbulence levels at the bellmouth exit are expected to be less than I percent, and will be measured in the near future along with the impeller inlet turbulence profile. The flow then enters the compressor and exits through a specially designed throttle valve at the entrance to the collector. The throttle valve consists of two concentric rings with overlapping holes drilled in each ring which slide relative to each other to produce a throttle. This throttle valve design was chosen to minimize circumferential asymmetry in the exit static pressure distribution such as is typically found in scroll-type collectors. The bellmouth, inlet transition piece, and shroud flow path were machined together to minimize any boundary layer disturbance due to a step in the flow path. Altitude exhaust capability of 660 mm-Hg (26 in-Hg) of vacuum enables mass flow rates up to 45 kg/sec. A 1.115 MW (1500-hp) electric motor and gear reducer drives the facility to a maximum speed of 2400 rpm. A complete description of the facility is provided by Wood et al. (1983). TEST COMPRESSOR During the design of the low speed compressor several condi- tions were imposed. First, the design should reflect the geometric and dynamic parameters that were deemed to be representative of modern compressors and second, the blade lean should not be so severe that laser access would be precluded. The design parameters for the low speed centrifugal compressor are given in table I while table 2 shows a comparison of some low speed centrifugal compres- sor stage parameters with those from several high speed centrifugal VOLUTE COLLECTOR - COMPRESSOR ASSEMBLY I/ -AIR STRAIGHTENER BELLMOUTH- 7 / / TRANSITION PIECE --BELLMOUTH INLET I • , 2'Tin ,.- SLIP-RING ASSEMBLIES r-MOTOR 2.4 m BEOPLATE- BEDPLTE/-/- /1 L MOO STND SPEED EXHAUST DRIVE FLEXIBLE SEAL \PLENUM-,/ / BLOWER I MW PESR AE/ - VRAL PRESSURE RAKE LOCAION ---- /ALTITUDE MOTOR STAND I VARIABLE SHROUD-- , THROTTLE / VALVE I,/ / / // SENSOR t / -TORQUE GEARI BOX// COUPLING Figure I Low speed centrifugal compressor facility. 2 /PDF Image | NASA Low-Speed Centrifugal Compressor for 3-D Viscous Code

PDF Search Title:

NASA Low-Speed Centrifugal Compressor for 3-D Viscous CodeOriginal File Name Searched:

a242473.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |