PDF Publication Title:

Text from PDF Page: 004

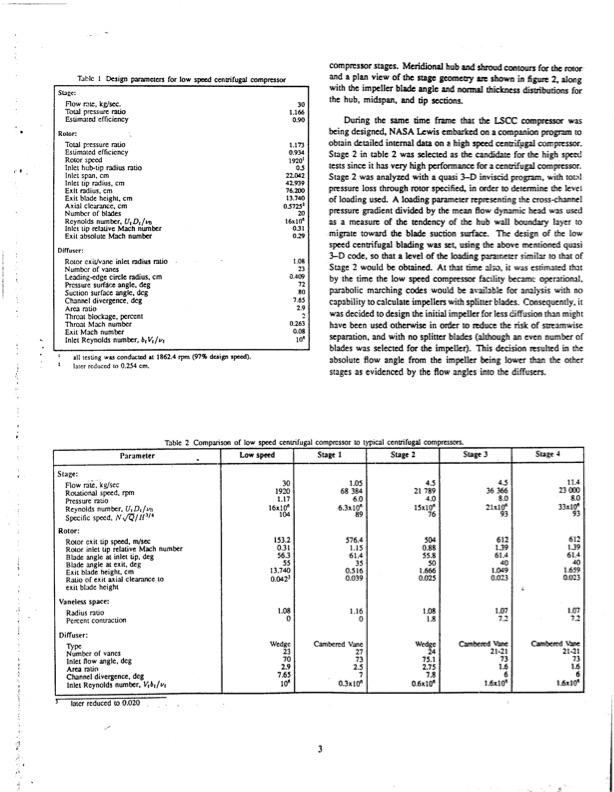

S Table I Design parameters for low speed centrifugal compressor rae,: and a plan view of the stage geometry are shown in figure 2, along with the impeller blade angle and normal thickness distributions for the hub, midspan, and tip sections. During the same time frame that the LSCC compressor was designed, NASA Lewis embarked on a companion program to obtain detailed internal data on a high speed centrifugal compressor. Stage 2 in table 2 was selected as the candidate for the high speed tests since it has very high performance for a centrifugal compressor. Stage 2 was analyzed with a quasi 3-D inviscid program, with total pressure loss through rotor specified, in order to determine the level of loading used. A loading parameter representing the cross-channel pressure gradient divided by the mean flow dynamic head was used as a measure of the tendency of the hub wall boundary layer to migrate toward the blade suction surface. The design of the low speed centrifugal blading was set, using the above mentioned quasi 3-D code, so that a level of the loading parameter similar to that of Stage 2 would be obtained. At that time also, it was estimated that by the time the low speed compressor facility became operational. parabolic marching codes would be available for analysis with no capability to calculate impellers with splitter blades. Consequently, it was decided to design the initial impeller for less diffusion than might have been used otherwise in order to reduce the risk of streamwise separation, and with no splitter blades (although an even number of blades was selected for the impeller). This decision resulted in the absolute flow angle from the impeller being lower than the other stages as evidenced by the flow angles into the diffusers. Mlow rat, kg/sec. Total pressure ratio Estimated efficiency 30 1.166 0.90 1.173 0.934 1920 0.5 22042 42939 76.200 13.740 0.5725' 20 16xl0' 0.31 0.29 1.08 23 0.409 72 80 7.65 2.9 2 0.263 0.08 In Rotor: :being Total pressure ratio Estimated efficiency Rotor spd Inlet hub-tip radius ratio Inlet span, cm Inlet tip radius, cm Exit radius, cm Exit blade height, cm Axial clearance, cm Number of blades Reynolds number, UDi/vn Inlet tip relative Mach number Exit absolute Mach number Dlffuscr: Rotor exit/vane inlet radius ratio Number of vanes Leading-edge circle radius, cm Pressure surface angle, deg Suction surface angle, deg Channel divergence, deg Area ratio Throat blockage, percent Throat Mach number Exit Mach number Inlet Reynolds number, b1V/t't all testing was conducted at 1862.4 rpm (97% design speed). later reduced to 0.254 cm. Stage: Parameter Low speed 30 1920 1.17 16xl0' 104 153.2 0.31 56.3 55 13.740 0.042' 1.08 0 Stage 1 Stage 2 1.05 4.5 68 384 21 789 6.0 4.0 6.3x10' 15xl0' 89 76 576.4 504 1.15 0.88 61.4 55.8 35 50 0.516 1.666 0.039 0.025 1.16 1.08 0 1.8 Cambered Vane Wedge 27 24 73 75.1 2.5 2.75 7 7.8 0.3x10'f 0.6xlO6 Stage 3 4.5 36 366 8.0 21x10' 93 612 1.39 61.4 40 1.049 0.023 1.07 7.2 Cambered Vane 21.21 73 1.6 6 5 Stage 4 11.4 23 000 8.0 33x10' 93 612 1.39 61.4 40 1.659 0.023 1.07 7.2 Cambered V'ane 21-21 73 1.6 6 1.6x106 Table 2 Comparison of low speed centrifugal compressor to typical centrifugal compressors. Flow rate, kg/sec Rotational speed, rpm Pressure ratio Reynolds number, UtD,/vn Specific speed, NvI'Q/H.14 Rotor: Rotor exit tip speed. m/sec Rotor inlet tip relative Mach number Blade angle at inlet tip. deg Blade angle at exit, deg Exit blade height, cm Ratio of exit axial clearance to exit blade height Vaneless space: Radius ratio Percent contraction Diffuser: Type Inlet Reynolds number, Vbl/vt Iol later reduced to 0.020 Wedge Number of vanes 23 Inlet flow angle, deg 70 Area ratio 2.9 Channel divergence, deg 7.65 3 compressor stages. Meridional hub and shroud contours for the rotor 1.6xl0PDF Image | NASA Low-Speed Centrifugal Compressor for 3-D Viscous Code

PDF Search Title:

NASA Low-Speed Centrifugal Compressor for 3-D Viscous CodeOriginal File Name Searched:

a242473.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |