PDF Publication Title:

Text from PDF Page: 002

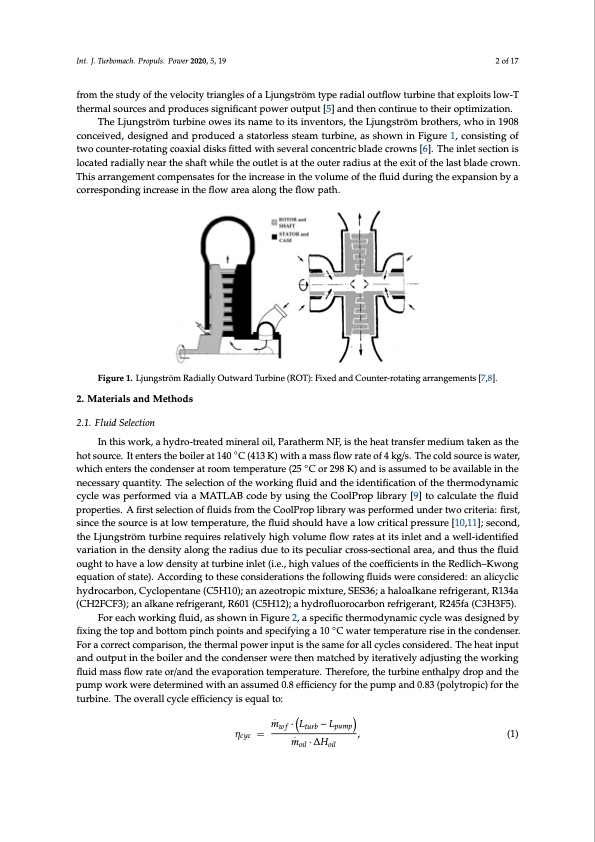

Int. J. Turbomach. Propuls. Power 2019, 4, x FOR PEER REVIEW 2 of 16 In light of the above, the purpose of this paper is to investigate the suitability of a special class of Ljungström turbines, specifically designed for the very large expansion rates of organic fluids in Int. J. Turbomach. Propuls. Power 2020, 5, 19 2 of 17 the range of power for which a preferred choice is not yet defined and consolidated. To do so, we will start from the study of the velocity triangles of a Ljungström type radial outflow turbine that efrxopmlotithselostwud-TytohfetrhmeavlesloucirtcyetsriandglpersoodfuacLesjusnignstirföicmanttypoewraedrioaluotpuutflto[5w] atunrdbitnhenthcaotnetxinpuloeittsolothwe-iTr othpetirmiazlastoiounr.ces and produces significant power output [5] and then continue to their optimization. The Ljungström turbiine owes its name to its inventors, the Ljungström brothers,, who in 1908 conceived,,deessigignneeddaannddpprordoduucecdeda astastaotrolerslessstesatemamturtbuirnbei,naes, sahsoswhnowinnFinguFriegu1,reco1n,scisotninsigstoifntgwof ctwouonctoeru-nrotetar-trinotgatcionagxcioalaxdiiaslkdsisfkitstefidttweditwhisthevservaelrcaol ncocenncternictribclabdlaedcercorwownsns[6[]6.].TThheeininlelettsseeccttiionis located radially near the shaft while the outlet iis att ttheoutterrradiiusattttheeexiittoffttheelalassttbblaladeeccrroown.. This arrangement compensates for the increase in the volume of the fflluid during the expansion by a corresponding increase in the ffllow area along the flflow path. Figure 1. Ljungström Radially Outward Turbine (ROT): Fixed and Counter-rotating arrangements [7,8]. Figure 1. Ljungström Radially Outward Turbine (ROT): Fixed and Counter-rotating arrangements [7,8]. 2. Materials and Methods 2.1M. FaltueirdiaSlseleacntdionMethods In this work, a hydro-treated mineral oil, Paratherm NF, is the heat transfer medium taken as the 2.1. Fluid Selection ◦ hotsource.Itenterstheboilerat140 C(413K)withamassflowrateof4kg/s.Thecoldsourceiswater, In this work, a hydro-treated mineral oil, Paratherm NF, is the heat transfer medium taken as which enters the condenser at room temperature (25 ◦C or 298 K) and is assumed to be available in the the hot source. It enters the boiler at 140 °C (413 K) with a mass flow rate of 4 kg/s. The cold source is necessary quantity. The selection of the working fluid and the identification of the thermodynamic water, which enters the condenser at room temperature (25 °C or 298 K) and is assumed to be cycle was performed via a MATLAB code by using the CoolProp library [9] to calculate the fluid available in the necessary quantity. The selection of the working fluid and the identification of the properties. A first selection of fluids from the CoolProp library was performed under two criteria: first, thermodynamic cycle was performed via a MATLAB code by using the CoolProp library [9] to since the source is at low temperature, the fluid should have a low critical pressure [10,11]; second, calculate the fluid properties. A first selection of fluids from the CoolProp library was performed the Ljungström turbine requires relatively high volume flow rates at its inlet and a well-identified under two criteria: first, since the source is at low temperature, the fluid should have a low critical variation in the density along the radius due to its peculiar cross-sectional area, and thus the fluid pressure [10,11]; second, the Ljungström turbine requires relatively high volume flow rates at its inlet ought to have a low density at turbine inlet (i.e., high values of the coefficients in the Redlich–Kwong and a well-identified variation in the density along the radius due to its peculiar cross-sectional area, equation of state). According to these considerations the following fluids were considered: an alicyclic and thus the fluid ought to have a low density at turbine inlet (i.e., high values of the coefficients in hydrocarbon, Cyclopentane (C5H10); an azeotropic mixture, SES36; a haloalkane refrigerant, R134a the Redlich–Kwong equation of state). According to these considerations the following fluids were (CH2FCF3); an alkane refrigerant, R601 (C5H12); a hydrofluorocarbon refrigerant, R245fa (C3H3F5). considered: an alicyclic hydrocarbon, Cyclopentane (C5H10); an azeotropic mixture, SES36; a For each working fluid, as shown in Figure 2, a specific thermodynamic cycle was designed by haloalkane refrigerant, R134a (CH2FCF3); an alkane refrigerant, R601 (C5H12); a hydrofluorocarbon fixing the top and bottom pinch points and specifying a 10 ◦C water temperature rise in the condenser. refrigerant, R245fa (C3H3F5). For a correct comparison, the thermal power input is the same for all cycles considered. The heat input For each working fluid, as shown in Figure 2, a specific thermodynamic cycle was designed by and output in the boiler and the condenser were then matched by iteratively adjusting the working fixing the top and bottom pinch points and specifying a 10 °C water temperature rise in the fluid mass flow rate or/and the evaporation temperature. Therefore, the turbine enthalpy drop and the condenser. For a correct comparison, the thermal power input is the same for all cycles considered. pump work were determined with an assumed 0.8 efficiency for the pump and 0.83 (polytropic) for the The heat input and output in the boiler and the condenser were then matched by iteratively adjusting turbine. The overall cycle efficiency is equal to: the working fluid mass flow rate or/and the evaporation temperature. Therefore, the turbine enthalpy . drop and the pump work were determinedmwith· aLn as−suLmed 0.8 efficiency for the pump and 0.83 w f turb pump η= , (1) (polytropic) for the turbine. The overall cycle efficiency is equal to: oil cyc m. · ∆H oilPDF Image | Optimal Design of a Ljungstrom Turbine for ORC Power

PDF Search Title:

Optimal Design of a Ljungstrom Turbine for ORC PowerOriginal File Name Searched:

ijtpp-05-00019.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |