PDF Publication Title:

Text from PDF Page: 009

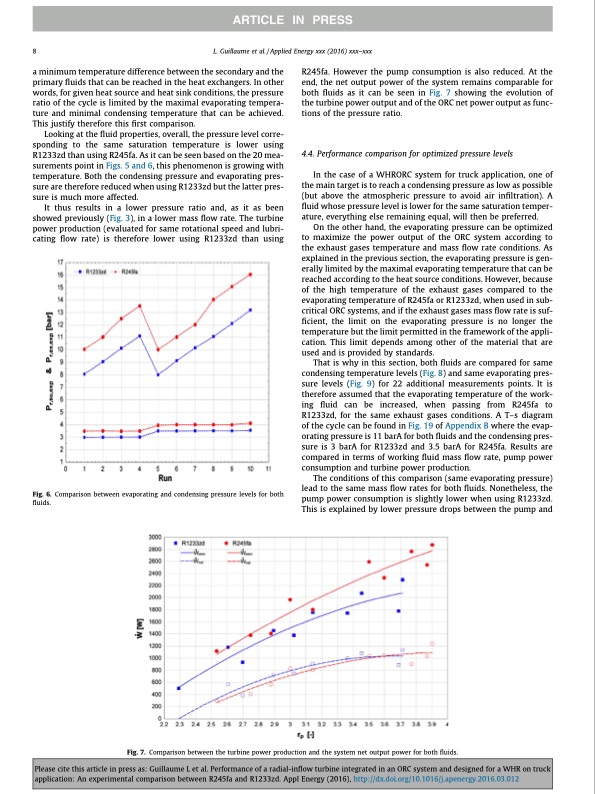

8 L. Guillaume et al. / Applied Energy xxx (2016) xxx–xxx a minimum temperature difference between the secondary and the primary fluids that can be reached in the heat exchangers. In other words, for given heat source and heat sink conditions, the pressure ratio of the cycle is limited by the maximal evaporating tempera- ture and minimal condensing temperature that can be achieved. This justify therefore this first comparison. Looking at the fluid properties, overall, the pressure level corre- sponding to the same saturation temperature is lower using R1233zd than using R245fa. As it can be seen based on the 20 mea- surements point in Figs. 5 and 6, this phenomenon is growing with temperature. Both the condensing pressure and evaporating pres- sure are therefore reduced when using R1233zd but the latter pres- sure is much more affected. It thus results in a lower pressure ratio and, as it as been showed previously (Fig. 3), in a lower mass flow rate. The turbine power production (evaluated for same rotational speed and lubri- cating flow rate) is therefore lower using R1233zd than using R245fa. However the pump consumption is also reduced. At the end, the net output power of the system remains comparable for both fluids as it can be seen in Fig. 7 showing the evolution of the turbine power output and of the ORC net power output as func- tions of the pressure ratio. 4.4. Performance comparison for optimized pressure levels In the case of a WHRORC system for truck application, one of the main target is to reach a condensing pressure as low as possible (but above the atmospheric pressure to avoid air infiltration). A fluid whose pressure level is lower for the same saturation temper- ature, everything else remaining equal, will then be preferred. On the other hand, the evaporating pressure can be optimized to maximize the power output of the ORC system according to the exhaust gases temperature and mass flow rate conditions. As explained in the previous section, the evaporating pressure is gen- erally limited by the maximal evaporating temperature that can be reached according to the heat source conditions. However, because of the high temperature of the exhaust gases compared to the evaporating temperature of R245fa or R1233zd, when used in sub- critical ORC systems, and if the exhaust gases mass flow rate is suf- ficient, the limit on the evaporating pressure is no longer the temperature but the limit permitted in the framework of the appli- cation. This limit depends among other of the material that are used and is provided by standards. That is why in this section, both fluids are compared for same condensing temperature levels (Fig. 8) and same evaporating pres- sure levels (Fig. 9) for 22 additional measurements points. It is therefore assumed that the evaporating temperature of the work- ing fluid can be increased, when passing from R245fa to R1233zd, for the same exhaust gases conditions. A T–s diagram of the cycle can be found in Fig. 19 of Appendix B where the evap- orating pressure is 11 barA for both fluids and the condensing pres- sure is 3 barA for R1233zd and 3.5 barA for R245fa. Results are compared in terms of working fluid mass flow rate, pump power consumption and turbine power production. The conditions of this comparison (same evaporating pressure) lead to the same mass flow rates for both fluids. Nonetheless, the pump power consumption is slightly lower when using R1233zd. This is explained by lower pressure drops between the pump and Fig. 6. Comparison between evaporating and condensing pressure levels for both fluids. Fig. 7. Comparison between the turbine power production and the system net output power for both fluids. Please cite this article in press as: Guillaume L et al. Performance of a radial-inflow turbine integrated in an ORC system and designed for a WHR on truck application: An experimental comparison between R245fa and R1233zd. Appl Energy (2016), http://dx.doi.org/10.1016/j.apenergy.2016.03.012PDF Image | WHR on truck ORC radial inflow turbine integrated

PDF Search Title:

WHR on truck ORC radial inflow turbine integratedOriginal File Name Searched:

orc-radial-turbine-truck-application.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |