PDF Publication Title:

Text from PDF Page: 002

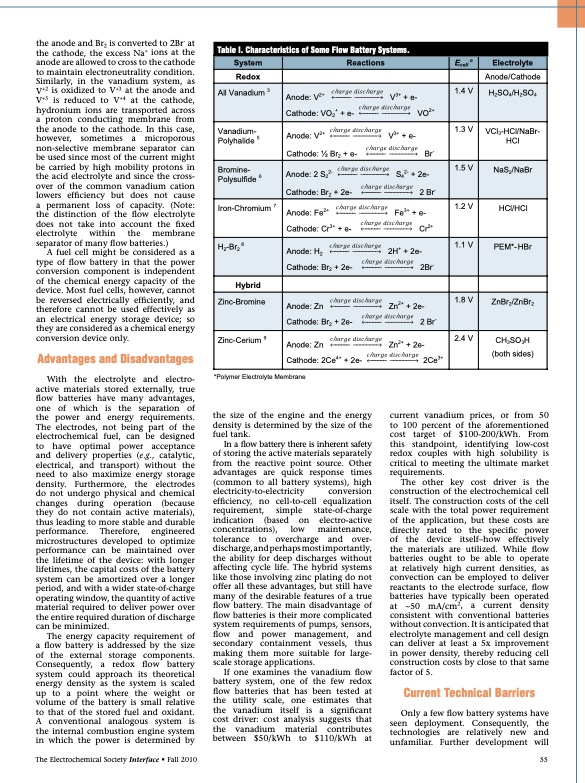

the anode and Br2 is converted to 2Br- at the cathode, the excess Na+ ions at the anode are allowed to cross to the cathode to maintain electroneutrality condition. Similarly, in the vanadium system, as V+2 is oxidized to V+3 at the anode and V+5 is reduced to V+4 at the cathode, hydronium ions are transported across a proton conducting membrane from the anode to the cathode. In this case, however, sometimes a microporous non-selective membrane separator can be used since most of the current might be carried by high mobility protons in the acid electrolyte and since the cross- over of the common vanadium cation lowers efficiency but does not cause a permanent loss of capacity. (Note: the distinction of the flow electrolyte does not take into account the fixed electrolyte within the membrane separator of many flow batteries.) A fuel cell might be considered as a type of flow battery in that the power conversion component is independent of the chemical energy capacity of the device. Most fuel cells, however, cannot be reversed electrically efficiently, and therefore cannot be used effectively as an electrical energy storage device; so they are considered as a chemical energy conversion device only. Advantages and Disadvantages With the electrolyte and electro- active materials stored externally, true flow batteries have many advantages, one of which is the separation of the power and energy requirements. The electrodes, not being part of the electrochemical fuel, can be designed to have optimal power acceptance and delivery properties (e.g., catalytic, electrical, and transport) without the need to also maximize energy storage density. Furthermore, the electrodes do not undergo physical and chemical changes during operation (because they do not contain active materials), thus leading to more stable and durable performance. Therefore, engineered microstructures developed to optimize performance can be maintained over the lifetime of the device: with longer lifetimes, the capital costs of the battery system can be amortized over a longer period, and with a wider state-of-charge operating window, the quantity of active material required to deliver power over the entire required duration of discharge can be minimized. The energy capacity requirement of a flow battery is addressed by the size of the external storage components. Consequently, a redox flow battery system could approach its theoretical energy density as the system is scaled up to a point where the weight or volume of the battery is small relative to that of the stored fuel and oxidant. A conventional analogous system is the internal combustion engine system in which the power is determined by Redox Vanadium- Polyhalide 5 Iron-Chromium 7 Hybrid Zinc-Cerium 9 2+ Anode:V Cathode: 1⁄2 Br2 + e- 2+ Anode: Fe Cathode: Cr3+ + e- Anode: Zn Cathode: 2Ce4+ + 2e- 3+ V +e- 1.3 V 1.2 V Anode/Cathode VCl3-HCl/NaBr- HCl HCl/HCl Table I. Characteristics of Some Flow Battery Systems. System Reactions Ecell o Electrolyte All Vanadium 3 Anode: V2+ V3+ + e- 1.4 V H2SO4/H2SO4 Cathode: VO2+ + e- VO2+ Bromine- 6 Anode: 2 S22- S42- + 2e- 1.5 V NaS2/NaBr Polysulfide Cathode: Br2 + 2e- 2 Br- 3+ Fe Br- + e- Cr2+ H2-Br2 8 Anode: H2 2H+ + 2e- 1.1 V PEM*- HBr Cathode: Br2 + 2e- 2Br- Zinc-Bromine Anode: Zn Zn2+ + 2e- 1.8 V ZnBr2/ZnBr2 Cathode: Br2 + 2e- 2 Br- Zn2+ + 2e- 2Ce3+ PEM* 2.4 V CH3SO3H (both sides) The Electrochemical Society Interface • Fall 2010 55 *Polymer Electrolyte Membrane the size of the engine and the energy density is determined by the size of the fuel tank. In a flow battery there is inherent safety of storing the active materials separately from the reactive point source. Other advantages are quick response times (common to all battery systems), high electricity-to-electricity conversion efficiency, no cell-to-cell equalization requirement, simple state-of-charge indication (based on electro-active concentrations), low maintenance, tolerance to overcharge and over- discharge, and perhaps most importantly, the ability for deep discharges without affecting cycle life. The hybrid systems like those involving zinc plating do not offer all these advantages, but still have many of the desirable features of a true flow battery. The main disadvantage of flow batteries is their more complicated system requirements of pumps, sensors, flow and power management, and secondary containment vessels, thus making them more suitable for large- scale storage applications. If one examines the vanadium flow battery system, one of the few redox flow batteries that has been tested at the utility scale, one estimates that the vanadium itself is a significant cost driver: cost analysis suggests that the vanadium material contributes between $50/kWh to $110/kWh at current vanadium prices, or from 50 to 100 percent of the aforementioned cost target of $100-200/kWh. From this standpoint, identifying low-cost redox couples with high solubility is critical to meeting the ultimate market requirements. The other key cost driver is the construction of the electrochemical cell itself. The construction costs of the cell scale with the total power requirement of the application, but these costs are directly rated to the specific power of the device itself–how effectively the materials are utilized. While flow batteries ought to be able to operate at relatively high current densities, as convection can be employed to deliver reactants to the electrode surface, flow batteries have typically been operated at ~50 mA/cm2, a current density consistent with conventional batteries without convection. It is anticipated that electrolyte management and cell design can deliver at least a 5x improvement in power density, thereby reducing cell construction costs by close to that same factor of 5. Current Technical Barriers Only a few flow battery systems have seen deployment. Consequently, the technologies are relatively new and unfamiliar. Further development willPDF Image | Flow Batteries 2010

PDF Search Title:

Flow Batteries 2010Original File Name Searched:

fal10_p054-056.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Salt water flow battery technology with low cost and great energy density that can be used for power storage and thermal storage. Let us de-risk your production using our license. Our aqueous flow battery is less cost than Tesla Megapack and available faster. Redox flow battery. No membrane needed like with Vanadium, or Bromine. Salgenx flow battery

| CONTACT TEL: 608-238-6001 Email: greg@salgenx.com | RSS | AMP |