PDF Publication Title:

Text from PDF Page: 002

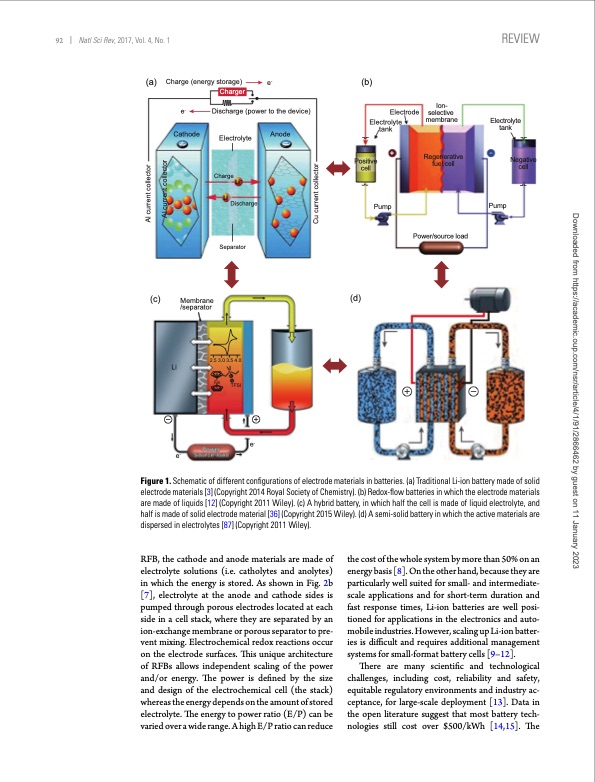

92 Natl Sci Rev, 2017, Vol. 4, No. 1 REVIEW (a) Charge (energy storage) e- Charger (b) Electrolyte tank + Pump (c) Membrane /separator (d) e- Cathode Discharge (power to the device) Electrode Ion- selective membrane Regenerative fuel cell Li e- 2.5 3.0 3.5 4.0 N Fe Electrolyte Charge Discharge Separator Anode Electrolyte tank Negative cell Pump TFSI e- Figure 1. Schematic of different configurations of electrode materials in batteries. (a) Traditional Li-ion battery made of solid electrode materials [3] (Copyright 2014 Royal Society of Chemistry). (b) Redox-flow batteries in which the electrode materials are made of liquids [12] (Copyright 2011 Wiley). (c) A hybrid battery, in which half the cell is made of liquid electrolyte, and half is made of solid electrode material [36] (Copyright 2015 Wiley). (d) A semi-solid battery in which the active materials are dispersed in electrolytes [87] (Copyright 2011 Wiley). RFB, the cathode and anode materials are made of electrolyte solutions (i.e. catholytes and anolytes) in which the energy is stored. As shown in Fig. 2b [7], electrolyte at the anode and cathode sides is pumped through porous electrodes located at each side in a cell stack, where they are separated by an ion-exchange membrane or porous separator to pre- vent mixing. Electrochemical redox reactions occur on the electrode surfaces. This unique architecture of RFBs allows independent scaling of the power and/or energy. The power is defined by the size and design of the electrochemical cell (the stack) whereas the energy depends on the amount of stored electrolyte. The energy to power ratio (E/P) can be varied over a wide range. A high E/P ratio can reduce the cost of the whole system by more than 50% on an energy basis [8]. On the other hand, because they are particularly well suited for small- and intermediate- scale applications and for short-term duration and fast response times, Li-ion batteries are well posi- tioned for applications in the electronics and auto- mobile industries. However, scaling up Li-ion batter- ies is difficult and requires additional management systems for small-format battery cells [9–12]. There are many scientific and technological challenges, including cost, reliability and safety, equitable regulatory environments and industry ac- ceptance, for large-scale deployment [13]. Data in the open literature suggest that most battery tech- nologies still cost over $500/kWh [14,15]. The Positive cell Power/source load Al current collector Al current collector Cu current collector Downloaded from https://academic.oup.com/nsr/article/4/1/91/2866462 by guest on 11 January 2023PDF Image | Progress in low cost redox flow batteries energy storage

PDF Search Title:

Progress in low cost redox flow batteries energy storageOriginal File Name Searched:

nww098.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Salt water flow battery technology with low cost and great energy density that can be used for power storage and thermal storage. Let us de-risk your production using our license. Our aqueous flow battery is less cost than Tesla Megapack and available faster. Redox flow battery. No membrane needed like with Vanadium, or Bromine. Salgenx flow battery

| CONTACT TEL: 608-238-6001 Email: greg@salgenx.com | RSS | AMP |