PDF Publication Title:

Text from PDF Page: 176

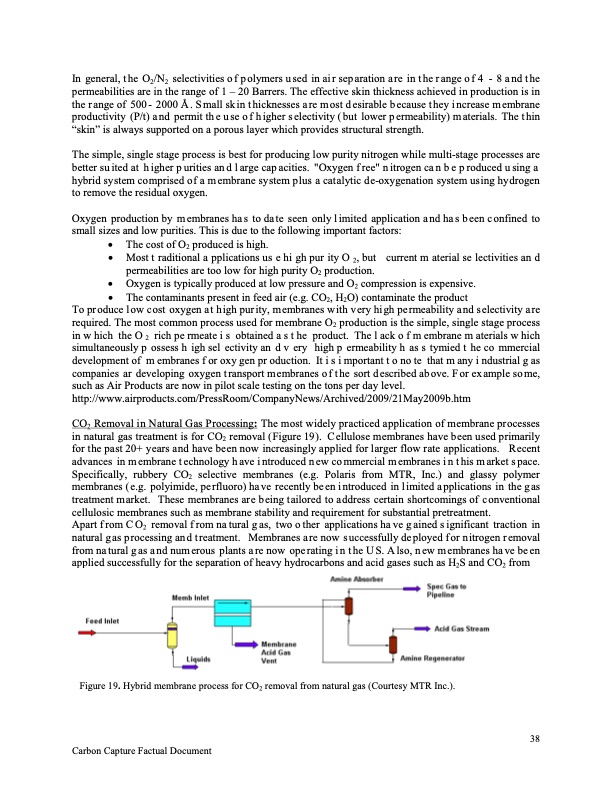

In general, the O2/N2 selectivities of polymers used in air separation are in the range of 4 - 8 and the permeabilities are in the range of 1 – 20 Barrers. The effective skin thickness achieved in production is in the range of 500- 2000 Å. Small skin thicknesses are most desirable because they increase membrane productivity (P/t) a nd permit th e u se o f h igher s electivity ( but lower p ermeability) m aterials. The t hin “skin” is always supported on a porous layer which provides structural strength. The simple, single stage process is best for producing low purity nitrogen while multi-stage processes are better su ited at h igher p urities an d l arge cap acities. "Oxygen f ree" n itrogen ca n b e p roduced u sing a hybrid system comprised of a membrane system plus a catalytic de-oxygenation system using hydrogen to remove the residual oxygen. Oxygen production by m embranes ha s to da te seen only l imited application a nd ha s b een c onfined to small sizes and low purities. This is due to the following important factors: • The cost of O2 produced is high. • Most t raditional a pplications us e hi gh pur ity O 2, but current m aterial se lectivities an d permeabilities are too low for high purity O2 production. • Oxygen is typically produced at low pressure and O2 compression is expensive. • The contaminants present in feed air (e.g. CO2, H2O) contaminate the product To produce low cost oxygen at high purity, membranes with very high permeability and selectivity are required. The most common process used for membrane O2 production is the simple, single stage process in w hich the O 2 rich pe rmeate i s obtained a s t he product. The l ack o f m embrane m aterials w hich simultaneously p ossess h igh sel ectivity an d v ery high p ermeability h as s tymied t he co mmercial development of m embranes f or oxy gen pr oduction. It i s i mportant t o no te that m any i ndustrial g as companies ar developing oxygen t ransport m embranes o f t he sort d escribed ab ove. F or ex ample so me, such as Air Products are now in pilot scale testing on the tons per day level. http://www.airproducts.com/PressRoom/CompanyNews/Archived/2009/21May2009b.htm CO2 Removal in Natural Gas Processing: The most widely practiced application of membrane processes in natural gas treatment is for CO2 removal (Figure 19). Cellulose membranes have been used primarily for the past 20+ years and have been now increasingly applied for larger flow rate applications. Recent advances in m embrane t echnology h ave i ntroduced n ew co mmercial m embranes i n t his m arket s pace. Specifically, rubbery CO2 selective membranes (e.g. Polaris from MTR, Inc.) and glassy polymer membranes ( e.g. polyimide, pe rfluoro) ha ve recently be en i ntroduced in l imited a pplications in the g as treatment market. These membranes are being tailored to address certain shortcomings of conventional cellulosic membranes such as membrane stability and requirement for substantial pretreatment. Apart f rom C O2 removal f rom na tural g as, two o ther applications ha ve g ained s ignificant traction in natural gas processing and treatment. Membranes are now successfully deployed for nitrogen removal from natural gas and numerous plants are now operating in the US. Also, new membranes have been applied successfully for the separation of heavy hydrocarbons and acid gases such as H2S and CO2 from Figure 19. Hybrid membrane process for CO2 removal from natural gas (Courtesy MTR Inc.). Carbon Capture Factual Document 38PDF Image | 2020 Carbon Capture

PDF Search Title:

2020 Carbon CaptureOriginal File Name Searched:

1291240.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |