PDF Publication Title:

Text from PDF Page: 130

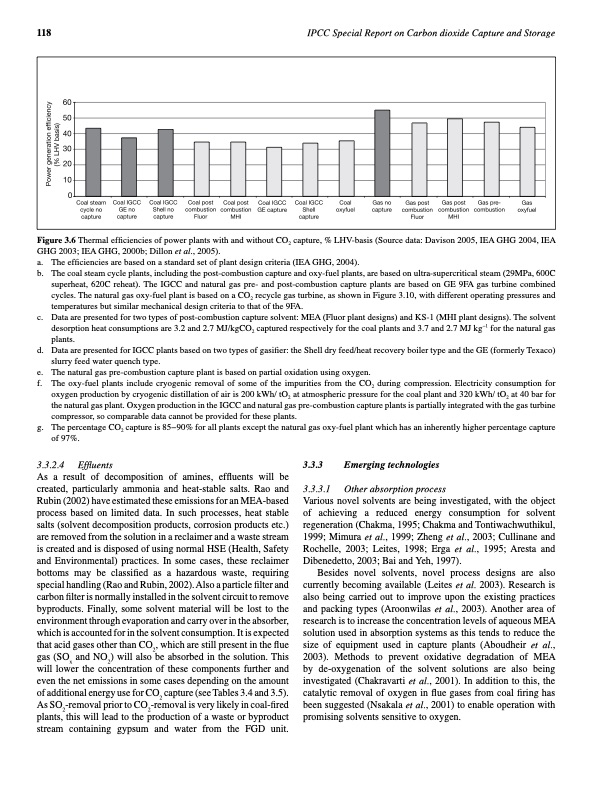

118 IPCC Special Report on Carbon dioxide Capture and Storage Figure 3.6 Thermal efficiencies of power plants with and without CO2 capture, % LHV-basis (Source data: Davison 2005, IEA GHG 2004, IEA GHG 2003; IEA GHG, 2000b; Dillon et al., 2005). a. The efficiencies are based on a standard set of plant design criteria (IEA GHG, 2004). b. The coal steam cycle plants, including the post-combustion capture and oxy-fuel plants, are based on ultra-supercritical steam (29MPa, 600C superheat, 620C reheat). The IGCC and natural gas pre- and post-combustion capture plants are based on GE 9FA gas turbine combined cycles. The natural gas oxy-fuel plant is based on a CO2 recycle gas turbine, as shown in Figure 3.10, with different operating pressures and temperatures but similar mechanical design criteria to that of the 9FA. c. Data are presented for two types of post-combustion capture solvent: MEA (Fluor plant designs) and KS-1 (MHI plant designs). The solvent desorption heat consumptions are 3.2 and 2.7 MJ/kgCO2 captured respectively for the coal plants and 3.7 and 2.7 MJ kg−1 for the natural gas plants. d. Data are presented for IGCC plants based on two types of gasifier: the Shell dry feed/heat recovery boiler type and the GE (formerly Texaco) slurry feed water quench type. e. The natural gas pre-combustion capture plant is based on partial oxidation using oxygen. f. The oxy-fuel plants include cryogenic removal of some of the impurities from the CO2 during compression. Electricity consumption for oxygen production by cryogenic distillation of air is 200 kWh/ tO2 at atmospheric pressure for the coal plant and 320 kWh/ tO2 at 40 bar for the natural gas plant. Oxygen production in the IGCC and natural gas pre-combustion capture plants is partially integrated with the gas turbine compressor, so comparable data cannot be provided for these plants. g. The percentage CO2 capture is 85−90% for all plants except the natural gas oxy-fuel plant which has an inherently higher percentage capture of 97%. 3.3.2.4 Effluents As a result of decomposition of amines, effluents will be created, particularly ammonia and heat-stable salts. Rao and Rubin (2002) have estimated these emissions for an MEA-based process based on limited data. In such processes, heat stable salts (solvent decomposition products, corrosion products etc.) are removed from the solution in a reclaimer and a waste stream is created and is disposed of using normal HSE (Health, Safety and Environmental) practices. In some cases, these reclaimer bottoms may be classified as a hazardous waste, requiring special handling (Rao and Rubin, 2002). Also a particle filter and carbon filter is normally installed in the solvent circuit to remove byproducts. Finally, some solvent material will be lost to the environment through evaporation and carry over in the absorber, which is accounted for in the solvent consumption. It is expected that acid gases other than CO2, which are still present in the flue gas (SOx and NO2) will also be absorbed in the solution. This will lower the concentration of these components further and even the net emissions in some cases depending on the amount of additional energy use for CO2 capture (see Tables 3.4 and 3.5). As SO2-removal prior to CO2-removal is very likely in coal-fired plants, this will lead to the production of a waste or byproduct stream containing gypsum and water from the FGD unit. 3.3.3 Emerging technologies Various novel solvents are being investigated, with the object of achieving a reduced energy consumption for solvent regeneration (Chakma, 1995; Chakma and Tontiwachwuthikul, 1999; Mimura et al., 1999; Zheng et al., 2003; Cullinane and Rochelle, 2003; Leites, 1998; Erga et al., 1995; Aresta and Dibenedetto, 2003; Bai and Yeh, 1997). 3.3.3.1 Other absorption process Besides novel solvents, novel process designs are also currently becoming available (Leites et al. 2003). Research is also being carried out to improve upon the existing practices and packing types (Aroonwilas et al., 2003). Another area of research is to increase the concentration levels of aqueous MEA solution used in absorption systems as this tends to reduce the size of equipment used in capture plants (Aboudheir et al., 2003). Methods to prevent oxidative degradation of MEA by de-oxygenation of the solvent solutions are also being investigated (Chakravarti et al., 2001). In addition to this, the catalytic removal of oxygen in flue gases from coal firing has been suggested (Nsakala et al., 2001) to enable operation with promising solvents sensitive to oxygen.PDF Image | CARBON DIOXIDE CAPTURE AND STORAGE

PDF Search Title:

CARBON DIOXIDE CAPTURE AND STORAGEOriginal File Name Searched:

srccs_wholereport.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |