PDF Publication Title:

Text from PDF Page: 131

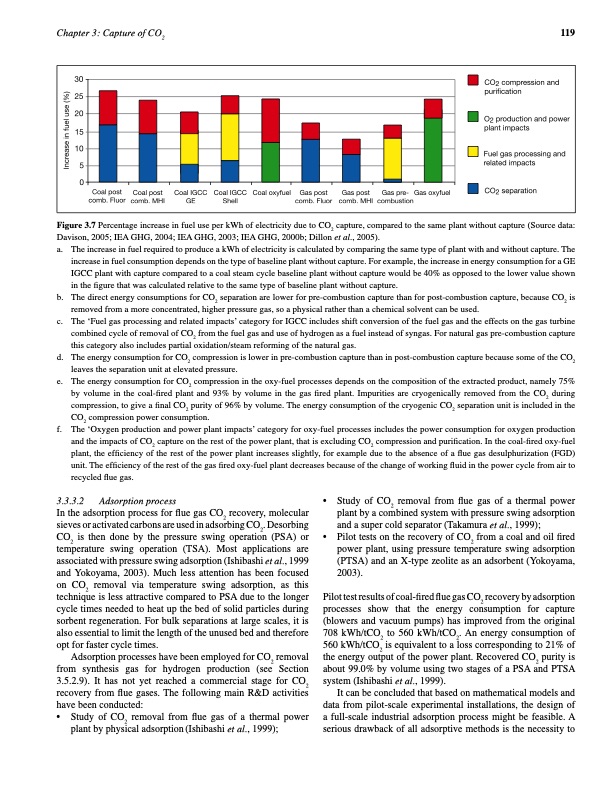

Chapter 3: Capture of CO2 119 Figure 3.7 Percentage increase in fuel use per kWh of electricity due to CO2 capture, compared to the same plant without capture (Source data: Davison, 2005; IEA GHG, 2004; IEA GHG, 2003; IEA GHG, 2000b; Dillon et al., 2005). a. The increase in fuel required to produce a kWh of electricity is calculated by comparing the same type of plant with and without capture. The increase in fuel consumption depends on the type of baseline plant without capture. For example, the increase in energy consumption for a GE IGCC plant with capture compared to a coal steam cycle baseline plant without capture would be 40% as opposed to the lower value shown in the figure that was calculated relative to the same type of baseline plant without capture. b. The direct energy consumptions for CO2 separation are lower for pre-combustion capture than for post-combustion capture, because CO2 is removed from a more concentrated, higher pressure gas, so a physical rather than a chemical solvent can be used. c. The ‘Fuel gas processing and related impacts’ category for IGCC includes shift conversion of the fuel gas and the effects on the gas turbine combined cycle of removal of CO2 from the fuel gas and use of hydrogen as a fuel instead of syngas. For natural gas pre-combustion capture this category also includes partial oxidation/steam reforming of the natural gas. d. The energy consumption for CO2 compression is lower in pre-combustion capture than in post-combustion capture because some of the CO2 leaves the separation unit at elevated pressure. e. The energy consumption for CO2 compression in the oxy-fuel processes depends on the composition of the extracted product, namely 75% by volume in the coal-fired plant and 93% by volume in the gas fired plant. Impurities are cryogenically removed from the CO2 during compression, to give a final CO2 purity of 96% by volume. The energy consumption of the cryogenic CO2 separation unit is included in the CO2 compression power consumption. f. The ‘Oxygen production and power plant impacts’ category for oxy-fuel processes includes the power consumption for oxygen production and the impacts of CO2 capture on the rest of the power plant, that is excluding CO2 compression and purification. In the coal-fired oxy-fuel plant, the efficiency of the rest of the power plant increases slightly, for example due to the absence of a flue gas desulphurization (FGD) unit. The efficiency of the rest of the gas fired oxy-fuel plant decreases because of the change of working fluid in the power cycle from air to recycled flue gas. 3.3.3.2 Adsorption process In the adsorption process for flue gas CO2 recovery, molecular sieves or activated carbons are used in adsorbing CO2. Desorbing CO2 is then done by the pressure swing operation (PSA) or temperature swing operation (TSA). Most applications are associated with pressure swing adsorption (Ishibashi et al., 1999 and Yokoyama, 2003). Much less attention has been focused on CO2 removal via temperature swing adsorption, as this technique is less attractive compared to PSA due to the longer cycle times needed to heat up the bed of solid particles during sorbent regeneration. For bulk separations at large scales, it is also essential to limit the length of the unused bed and therefore opt for faster cycle times. • Study of CO2 removal from flue gas of a thermal power plant by a combined system with pressure swing adsorption and a super cold separator (Takamura et al., 1999); Adsorption processes have been employed for CO2 removal from synthesis gas for hydrogen production (see Section 3.5.2.9). It has not yet reached a commercial stage for CO2 recovery from flue gases. The following main R&D activities have been conducted: • Study of CO2 removal from flue gas of a thermal power Pilot test results of coal-fired flue gas CO2 recovery by adsorption processes show that the energy consumption for capture (blowers and vacuum pumps) has improved from the original 708 kWh/tCO2 to 560 kWh/tCO2. An energy consumption of 560 kWh/tCO2 is equivalent to a loss corresponding to 21% of the energy output of the power plant. Recovered CO2 purity is about 99.0% by volume using two stages of a PSA and PTSA system (Ishibashi et al., 1999). plant by physical adsorption (Ishibashi et al., 1999); It can be concluded that based on mathematical models and data from pilot-scale experimental installations, the design of a full-scale industrial adsorption process might be feasible. A serious drawback of all adsorptive methods is the necessity to • Pilot tests on the recovery of CO2 from a coal and oil fired power plant, using pressure temperature swing adsorption (PTSA) and an X-type zeolite as an adsorbent (Yokoyama, 2003).PDF Image | CARBON DIOXIDE CAPTURE AND STORAGE

PDF Search Title:

CARBON DIOXIDE CAPTURE AND STORAGEOriginal File Name Searched:

srccs_wholereport.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |