PDF Publication Title:

Text from PDF Page: 137

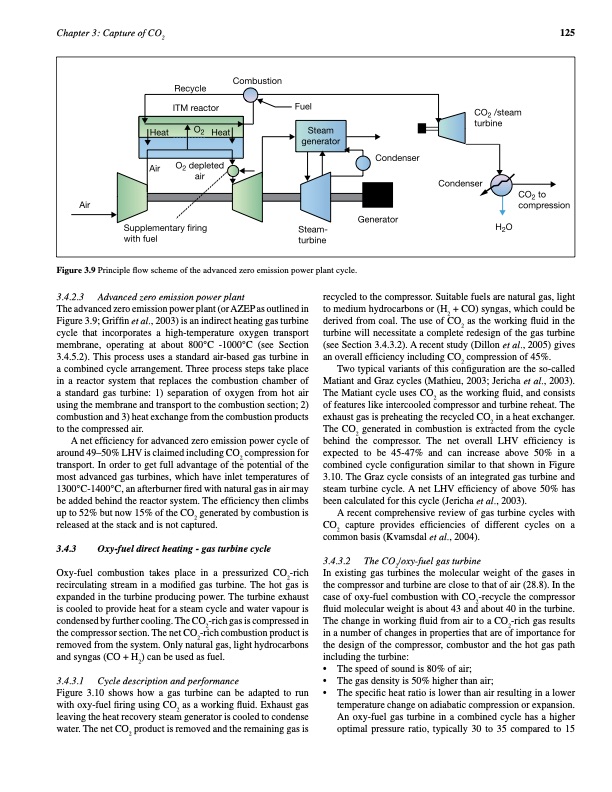

Chapter 3: Capture of CO2 125 Figure 3.9 Principle flow scheme of the advanced zero emission power plant cycle. 3.4.2.3 Advanced zero emission power plant recycled to the compressor. Suitable fuels are natural gas, light to medium hydrocarbons or (H2 + CO) syngas, which could be derived from coal. The use of CO2 as the working fluid in the turbine will necessitate a complete redesign of the gas turbine (see Section 3.4.3.2). A recent study (Dillon et al., 2005) gives an overall efficiency including CO2 compression of 45%. The advanced zero emission power plant (or AZEP as outlined in Figure 3.9; Griffin et al., 2003) is an indirect heating gas turbine cycle that incorporates a high-temperature oxygen transport membrane, operating at about 800°C -1000°C (see Section 3.4.5.2). This process uses a standard air-based gas turbine in a combined cycle arrangement. Three process steps take place in a reactor system that replaces the combustion chamber of a standard gas turbine: 1) separation of oxygen from hot air using the membrane and transport to the combustion section; 2) combustion and 3) heat exchange from the combustion products to the compressed air. 3.4.3 Oxy-fuel direct heating - gas turbine cycle Oxy-fuel combustion takes place in a pressurized CO2-rich recirculating stream in a modified gas turbine. The hot gas is expanded in the turbine producing power. The turbine exhaust is cooled to provide heat for a steam cycle and water vapour is condensed by further cooling. The CO2-rich gas is compressed in the compressor section. The net CO2-rich combustion product is removed from the system. Only natural gas, light hydrocarbons and syngas (CO + H2) can be used as fuel. Figure 3.10 shows how a gas turbine can be adapted to run with oxy-fuel firing using CO2 as a working fluid. Exhaust gas leaving the heat recovery steam generator is cooled to condense water. The net CO2 product is removed and the remaining gas is Two typical variants of this configuration are the so-called Matiant and Graz cycles (Mathieu, 2003; Jericha et al., 2003). The Matiant cycle uses CO2 as the working fluid, and consists of features like intercooled compressor and turbine reheat. The exhaust gas is preheating the recycled CO2 in a heat exchanger. The CO2 generated in combustion is extracted from the cycle behind the compressor. The net overall LHV efficiency is expected to be 45-47% and can increase above 50% in a combined cycle configuration similar to that shown in Figure 3.10. The Graz cycle consists of an integrated gas turbine and steam turbine cycle. A net LHV efficiency of above 50% has been calculated for this cycle (Jericha et al., 2003). A net efficiency for advanced zero emission power cycle of around 49–50% LHV is claimed including CO2 compression for transport. In order to get full advantage of the potential of the most advanced gas turbines, which have inlet temperatures of 1300°C-1400°C, an afterburner fired with natural gas in air may be added behind the reactor system. The efficiency then climbs up to 52% but now 15% of the CO2 generated by combustion is released at the stack and is not captured. A recent comprehensive review of gas turbine cycles with CO2 capture provides efficiencies of different cycles on a common basis (Kvamsdal et al., 2004). 3.4.3.1 Cycle description and performance • The speed of sound is 80% of air; • The gas density is 50% higher than air; • The specific heat ratio is lower than air resulting in a lower 3.4.3.2 The CO2/oxy-fuel gas turbine In existing gas turbines the molecular weight of the gases in the compressor and turbine are close to that of air (28.8). In the case of oxy-fuel combustion with CO2-recycle the compressor fluid molecular weight is about 43 and about 40 in the turbine. The change in working fluid from air to a CO2-rich gas results in a number of changes in properties that are of importance for the design of the compressor, combustor and the hot gas path including the turbine: temperature change on adiabatic compression or expansion. An oxy-fuel gas turbine in a combined cycle has a higher optimal pressure ratio, typically 30 to 35 compared to 15PDF Image | CARBON DIOXIDE CAPTURE AND STORAGE

PDF Search Title:

CARBON DIOXIDE CAPTURE AND STORAGEOriginal File Name Searched:

srccs_wholereport.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |