PDF Publication Title:

Text from PDF Page: 138

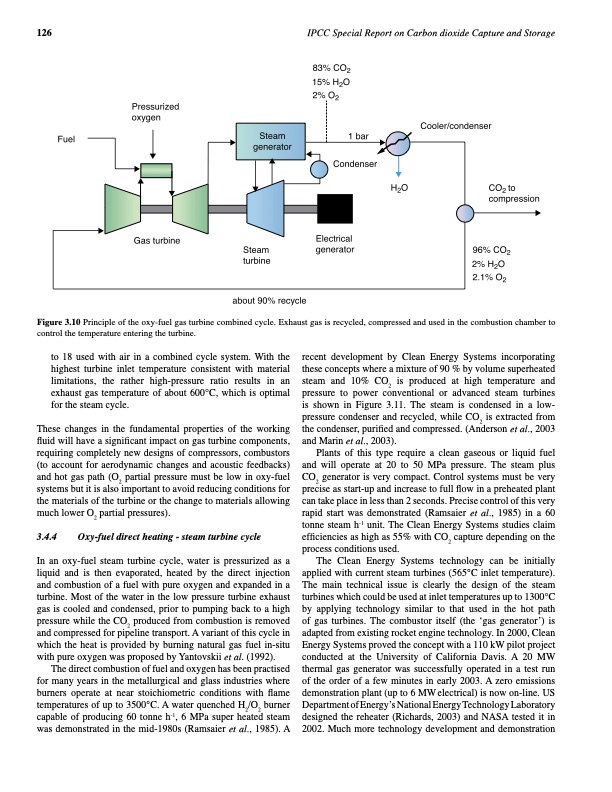

126 IPCC Special Report on Carbon dioxide Capture and Storage Figure 3.10 Principle of the oxy-fuel gas turbine combined cycle. Exhaust gas is recycled, compressed and used in the combustion chamber to control the temperature entering the turbine. to 18 used with air in a combined cycle system. With the highest turbine inlet temperature consistent with material limitations, the rather high-pressure ratio results in an exhaust gas temperature of about 600°C, which is optimal for the steam cycle. These changes in the fundamental properties of the working fluid will have a significant impact on gas turbine components, requiring completely new designs of compressors, combustors (to account for aerodynamic changes and acoustic feedbacks) and hot gas path (O2 partial pressure must be low in oxy-fuel systems but it is also important to avoid reducing conditions for the materials of the turbine or the change to materials allowing much lower O2 partial pressures). 3.4.4 Oxy-fuel direct heating - steam turbine cycle In an oxy-fuel steam turbine cycle, water is pressurized as a liquid and is then evaporated, heated by the direct injection and combustion of a fuel with pure oxygen and expanded in a turbine. Most of the water in the low pressure turbine exhaust gas is cooled and condensed, prior to pumping back to a high pressure while the CO2 produced from combustion is removed and compressed for pipeline transport. A variant of this cycle in which the heat is provided by burning natural gas fuel in-situ with pure oxygen was proposed by Yantovskii et al. (1992). Plants of this type require a clean gaseous or liquid fuel and will operate at 20 to 50 MPa pressure. The steam plus CO2 generator is very compact. Control systems must be very precise as start-up and increase to full flow in a preheated plant can take place in less than 2 seconds. Precise control of this very rapid start was demonstrated (Ramsaier et al., 1985) in a 60 tonne steam h-1 unit. The Clean Energy Systems studies claim efficiencies as high as 55% with CO2 capture depending on the process conditions used. The direct combustion of fuel and oxygen has been practised for many years in the metallurgical and glass industries where burners operate at near stoichiometric conditions with flame temperatures of up to 3500°C. A water quenched H2/O2 burner capable of producing 60 tonne h-1, 6 MPa super heated steam was demonstrated in the mid-1980s (Ramsaier et al., 1985). A The Clean Energy Systems technology can be initially applied with current steam turbines (565°C inlet temperature). The main technical issue is clearly the design of the steam turbines which could be used at inlet temperatures up to 1300°C by applying technology similar to that used in the hot path of gas turbines. The combustor itself (the ‘gas generator’) is adapted from existing rocket engine technology. In 2000, Clean Energy Systems proved the concept with a 110 kW pilot project conducted at the University of California Davis. A 20 MW thermal gas generator was successfully operated in a test run of the order of a few minutes in early 2003. A zero emissions demonstration plant (up to 6 MW electrical) is now on-line. US Department of Energy’s National Energy Technology Laboratory designed the reheater (Richards, 2003) and NASA tested it in 2002. Much more technology development and demonstration recent development by Clean Energy Systems incorporating these concepts where a mixture of 90 % by volume superheated steam and 10% CO2 is produced at high temperature and pressure to power conventional or advanced steam turbines is shown in Figure 3.11. The steam is condensed in a low- pressure condenser and recycled, while CO2 is extracted from the condenser, purified and compressed. (Anderson et al., 2003 and Marin et al., 2003).PDF Image | CARBON DIOXIDE CAPTURE AND STORAGE

PDF Search Title:

CARBON DIOXIDE CAPTURE AND STORAGEOriginal File Name Searched:

srccs_wholereport.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |