PDF Publication Title:

Text from PDF Page: 003

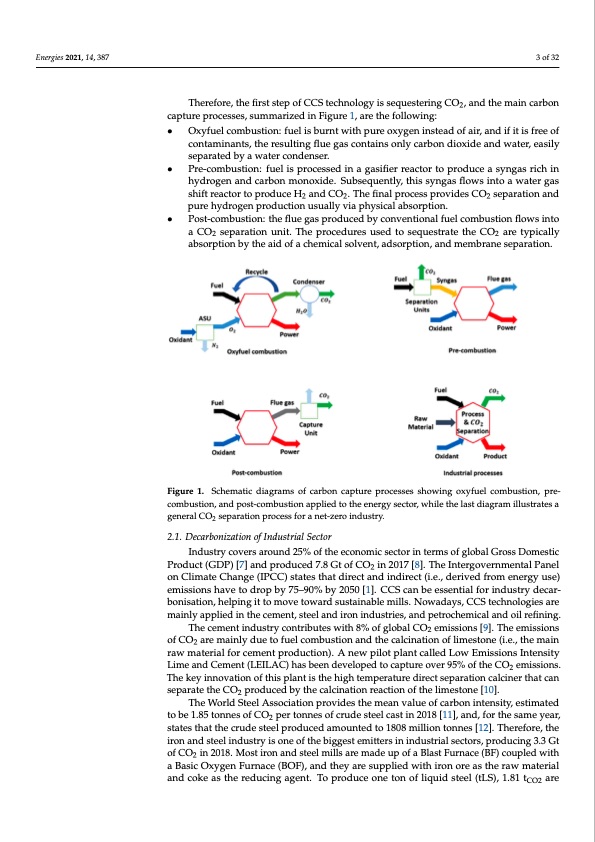

Energies 2021, 14, x FOR PEER REVIEW 3 of 33 Energies 2021, 14, 387 3 of 32 and involves CO2 separation, compression, and transportation (via pipeline or shipping) and its storage in a geological site (e.g., saline aquifer, oil and/or gas reservoir). Therefore, the first step of CCS technology is sequestering CO2, and the main carbon Therefore, the first step of CCS technology is sequestering CO , and the main carbon capture processes, summarized in Figure 1, are the following: 2 • • • capture processes, summarized in Figure 1, are the following: Oxyfuel combustion: fuel is burnt with pure oxygen instead of air, and if it is free of • Oxyfuel combustion: fuel is burnt with pure oxygen instead of air, and if it is free of contaminants, the resulting flue gas contains only carbon dioxide and water, easily contaminants, the resulting flue gas contains only carbon dioxide and water, easily separated by a water condenser. separated by a water condenser. Pre-combustion: fuel is processed in a gasifier reactor to produce a syngas rich in hy- • Pre-combustion: fuel is processed in a gasifier reactor to produce a syngas rich in drogen and carbon monoxide. Subsequently, this syngas flows into a water gas shift hydrogen and carbon monoxide. Subsequently, this syngas flows into a water gas reactor to produce H2 and CO2. The final process provides CO2 separation and pure shiftreactortoproduceH andCO.ThefinalprocessprovidesCO separationand hydrogen production usually v2 ia physic2al absorption. 2 pure hydrogen production usually via physical absorption. Post-combustion: the flue gas produced by conventional fuel combustion flows into a • Post-combustion: the flue gas produced by conventional fuel combustion flows into CO2 separation unit. The procedures used to sequestrate the CO2 are typically absorp- a CO separation unit. The procedures used to sequestrate the CO are typically tion by th2e aid of a chemical solvent, adsorption, and membrane separation2. absorption by the aid of a chemical solvent, adsorption, and membrane separation. Figure 1. Schematic diagrams of carbon capture processes showing oxyfuel combustion, pre- Figure 1. Schematic diagrams of carbon capture processes showing oxyfuel combustion, pre-com- combustion, and post-combustion applied to the energy sector, while the last diagram illustrates a bustion, and post-combustion applied to the energy sector, while the last diagram illustrates a general CO2 separation process for a net-zero industry. general CO2 separation process for a net-zero industry. 2.1. Decarbonization of Industrial Sector 2.1. Decarbonization of Industrial Sector Industry covers around 25% of the economic sector in terms of global Gross Domestic Industry covers around 25% of the economic sector in terms of global Gross Domestic Product (GDP) [7] and produced 7.8 Gt of CO2 in 2017 [8]. The Intergovernmental Panel Product (GDP) [7] and produced 7.8 Gt of CO2 in 2017 [8]. The Intergovernmental Panel on Climate Change (IPCC) states that direct and indirect (i.e., derived from energy use) on Climate Change (IPCC) states that direct and indirect (i.e., derived from energy use) emissions have to drop by 75–90% by 2050 [1]. CCS can be essential for industry decar- emissions have to drop by 75–90% by 2050 [1]. CCS can be essential for industry decar- bonisation, helping it to move toward sustainable mills. Nowadays, CCS technologies are bonisation, helping it to move toward sustainable mills. Nowadays, CCS technologies are ing. mainly applied in the cement, steel and iron industries, and petrochemical and oil refining. mainly applied in the cement, steel and iron industries, and petrochemical and oil refin- The cement industry contributes with 8% of global CO2 emissions [9]. The emissions of CO2 are mainly due to fuel combustion and the calcination of limestone (i.e., the main The cement industry contributes with 8% of global CO2 emissions [9]. The emissions raw material for cement production). A new pilot plant called Low Emissions Intensity of CO2 are mainly due to fuel combustion and the calcination of limestone (i.e., the main Lime and Cement (LEILAC) has been developed to capture over 95% of the CO2 emissions. raw material for cement production). A new pilot plant called Low Emissions Intensity The key innovation of this plant is the high temperature direct separation calciner that can Lime and Cement (LEILAC) has been developed to capture over 95% of the CO2 emis- separate the CO2 produced by the calcination reaction of the limestone [10]. sions. The key innovation of this plant is the high temperature direct separation calciner The World Steel Association provides the mean value of carbon intensity, estimated that can separate the CO2 produced by the calcination reaction of the limestone [10]. to be 1.85 tonnes of CO2 per tonnes of crude steel cast in 2018 [11], and, for the same year, The World Steel Association provides the mean value of carbon intensity, estimated states that the crude steel produced amounted to 1808 million tonnes [12]. Therefore, the to be 1.85 tonnes of CO2 per tonnes of crude steel cast in 2018 [11], and, for the same year, iron and steel industry is one of the biggest emitters in industrial sectors, producing 3.3 Gt of CO2 in 2018. Most iron and steel mills are made up of a Blast Furnace (BF) coupled with a Basic Oxygen Furnace (BOF), and they are supplied with iron ore as the raw material and coke as the reducing agent. To produce one ton of liquid steel (tLS), 1.81 tCO2 arePDF Image | Energies 14

PDF Search Title:

Energies 14Original File Name Searched:

energies-14-00387.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |