PDF Publication Title:

Text from PDF Page: 002

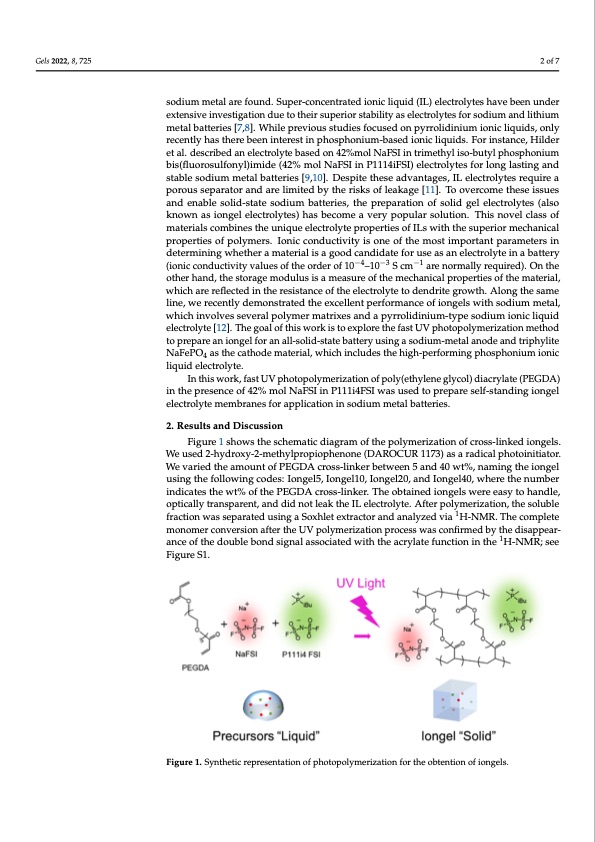

Gels 2022, 8, 725 2 of 7 Gels 2022, 8, x FOR PEER REVIEW sodium metal are found. Super-concentrated ionic liquid (IL) electrolytes have been under extensive investigation due to their superior stability as electrolytes for sodium and lithium metal batteries [7,8]. While previous studies focused on pyrrolidinium ionic liquids, only recently has there been interest in phosphonium-based ionic liquids. For instance, Hilder et al. described an electrolyte based on 42%mol NaFSI in trimethyl iso-butyl phosphonium bis(fluorosulfonyl)imide (42% mol NaFSI in P1114iFSI) electrolytes for long lasting and stable sodium metal batteries [9,10]. Despite these advantages, IL electrolytes require a porous separator and are limited by the risks of leakage [11]. To overcome these issues and enable solid-state sodium batteries, the preparation of solid gel electrolytes (also known as iongel electrolytes) has become a very popular solution. This novel class of materials combines the unique electrolyte properties of ILs with the superior mechanical properties of polymers. Ionic conductivity is one of the most important parameters in determining whether a material is a good candidate for use as an electrolyte in a battery (ionic conductivity values of the order of 10−4–10−3 S cm−1 are normally required). On the other hand, the storage modulus is a measure of the mechanical properties of the material, which are reflected in the resistance of the electrolyte to dendrite growth. Along the same line, we recently demonstrated the excellent performance of iongels with sodium metal, which involves several polymer matrixes and a pyrrolidinium-type sodium ionic liquid electrolyte [12]. The goal of this work is to explore the fast UV photopolymerization method to prepare an iongel for an all-solid-state battery using a sodium-metal anode and triphylite NaFePO4 as the cathode material, which includes the high-performing phosphonium ionic liquid electrolyte. In this work, fast UV photopolymerization of poly(ethylene glycol) diacrylate (PEGDA) in the presence of 42% mol NaFSI in P111i4FSI was used to prepare self-standing iongel electrolyte membranes for application in sodium metal batteries. 2. Results and Discussion Figure 1 shows the schematic diagram of the polymerization of cross-linked iongels. We used 2-hydroxy-2-methylpropiophenone (DAROCUR 1173) as a radical photoinitiator. We varied the amount of PEGDA cross-linker between 5 and 40 wt%, naming the iongel using the following codes: Iongel5, Iongel10, Iongel20, and Iongel40, where the number indicates the wt% of the PEGDA cross-linker. The obtained iongels were easy to handle, optically transparent, and did not leak the IL electrolyte. After polymerization, the soluble fraction was separated using a Soxhlet extractor and analyzed via 1H-NMR. The complete monomer conversion after the UV polymerization process was confirmed by the disappear- 1 3 of 8 anceofthedoublebondsignalassociatedwiththeacrylatefunctioninthe H-NMR;see Figure S1. Figure 1. Synthetic representation of photopolymerization for the obtention of iongels. Figure 1. Synthetic representation of photopolymerization for the obtention of iongels. 2.1. Dynamic Mechanical Analysis (DMA) DMA was used to determine the effect of PEGDA crosslinker content on the storage modulus of the phosphonium iongel electrolytes. Figure 2 shows the storage modulus as a function of temperature (measured between –40 and 90 °C), consisting of two character- istic regions. In the temperature region below 0 °C, a significant modulus change wasPDF Image | Phosphonium Iongels for Solid-State Sodium Metal Batteries

PDF Search Title:

Phosphonium Iongels for Solid-State Sodium Metal BatteriesOriginal File Name Searched:

gels-08-00725.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Salt water flow battery technology with low cost and great energy density that can be used for power storage and thermal storage. Let us de-risk your production using our license. Our aqueous flow battery is less cost than Tesla Megapack and available faster. Redox flow battery. No membrane needed like with Vanadium, or Bromine. Salgenx flow battery

| CONTACT TEL: 608-238-6001 Email: greg@salgenx.com | RSS | AMP |