PDF Publication Title:

Text from PDF Page: 002

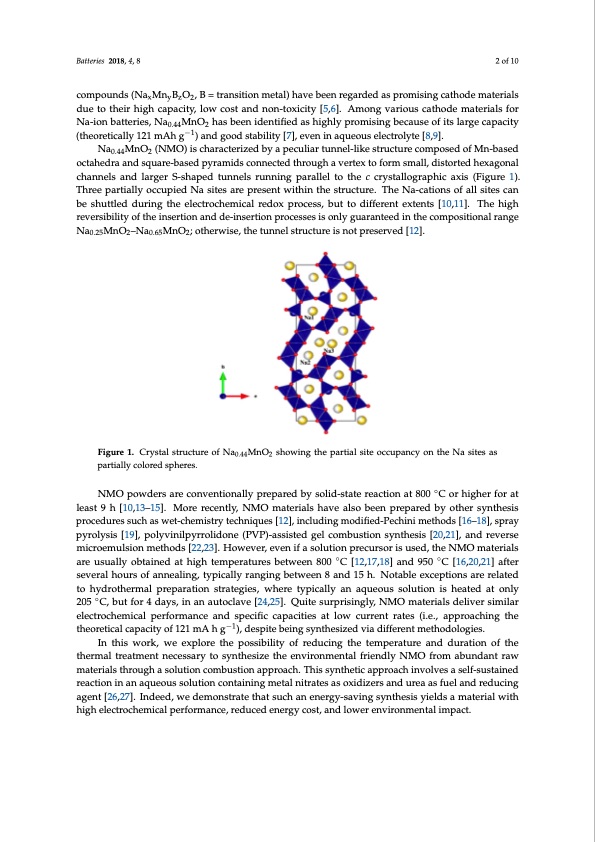

Batteries 2018, 4, 8 2 of 10 compounds (NaxMnyBzO2, B = transition metal) have been regarded as promising cathode materials due to their high capacity, low cost and non-toxicity [5,6]. Among various cathode materials for Na-ion batteries, Na0.44MnO2 has been identified as highly promising because of its large capacity (theoretically 121 mAh g−1) and good stability [7], even in aqueous electrolyte [8,9]. Na0.44MnO2 (NMO) is characterized by a peculiar tunnel-like structure composed of Mn-based octahedra and square-based pyramids connected through a vertex to form small, distorted hexagonal channels and larger S-shaped tunnels running parallel to the c crystallographic axis (Figure 1). Three partially occupied Na sites are present within the structure. The Na-cations of all sites can be shuttled during the electrochemical redox process, but to different extents [10,11]. The high reversibility of the insertion and de-insertion processes is only guaranteed in the compositional range Na0.25MnO2–Na0.65MnO2; otherwise, the tunnel structure is not preserved [12]. Figure 1. Crystal structure of Na0.44MnO2 showing the partial site occupancy on the Na sites as partially colored spheres. NMO powders are conventionally prepared by solid-state reaction at 800 ◦C or higher for at least 9 h [10,13–15]. More recently, NMO materials have also been prepared by other synthesis procedures such as wet-chemistry techniques [12], including modified-Pechini methods [16–18], spray pyrolysis [19], polyvinilpyrrolidone (PVP)-assisted gel combustion synthesis [20,21], and reverse microemulsion methods [22,23]. However, even if a solution precursor is used, the NMO materials are usually obtained at high temperatures between 800 ◦C [12,17,18] and 950 ◦C [16,20,21] after several hours of annealing, typically ranging between 8 and 15 h. Notable exceptions are related to hydrothermal preparation strategies, where typically an aqueous solution is heated at only 205 ◦C, but for 4 days, in an autoclave [24,25]. Quite surprisingly, NMO materials deliver similar electrochemical performance and specific capacities at low current rates (i.e., approaching the theoretical capacity of 121 mA h g−1), despite being synthesized via different methodologies. In this work, we explore the possibility of reducing the temperature and duration of the thermal treatment necessary to synthesize the environmental friendly NMO from abundant raw materials through a solution combustion approach. This synthetic approach involves a self-sustained reaction in an aqueous solution containing metal nitrates as oxidizers and urea as fuel and reducing agent [26,27]. Indeed, we demonstrate that such an energy-saving synthesis yields a material with high electrochemical performance, reduced energy cost, and lower environmental impact.PDF Image | Sodium-Ion Batteries Obtained through Urea Based

PDF Search Title:

Sodium-Ion Batteries Obtained through Urea BasedOriginal File Name Searched:

10281-250332.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Salt water flow battery technology with low cost and great energy density that can be used for power storage and thermal storage. Let us de-risk your production using our license. Our aqueous flow battery is less cost than Tesla Megapack and available faster. Redox flow battery. No membrane needed like with Vanadium, or Bromine. Salgenx flow battery

| CONTACT TEL: 608-238-6001 Email: greg@salgenx.com | RSS | AMP |