PDF Publication Title:

Text from PDF Page: 004

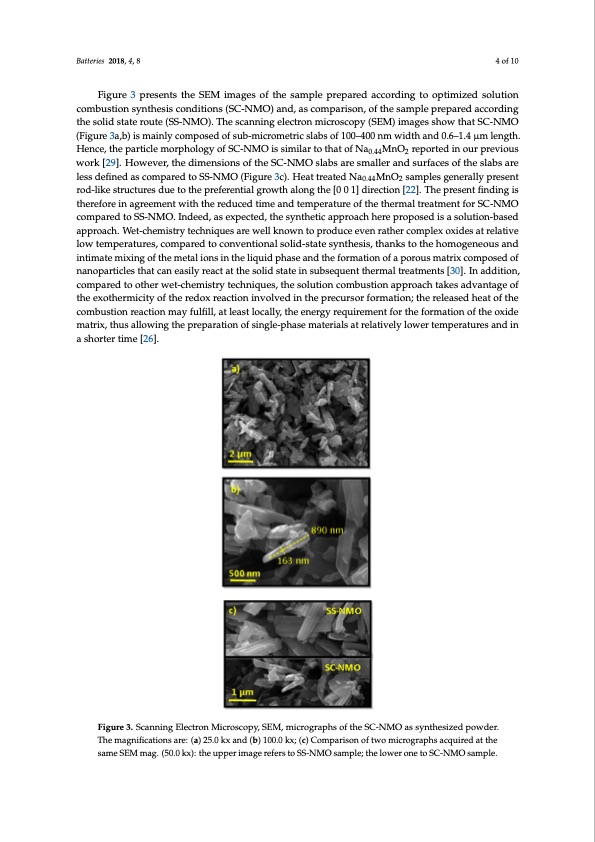

Batteries 2018, 4, 8 4 of 10 Figure 3 presents the SEM images of the sample prepared according to optimized solution combustion synthesis conditions (SC-NMO) and, as comparison, of the sample prepared according the solid state route (SS-NMO). The scanning electron microscopy (SEM) images show that SC-NMO (Figure 3a,b) is mainly composed of sub-micrometric slabs of 100–400 nm width and 0.6–1.4 μm length. Hence, the particle morphology of SC-NMO is similar to that of Na0.44MnO2 reported in our previous work [29]. However, the dimensions of the SC-NMO slabs are smaller and surfaces of the slabs are less defined as compared to SS-NMO (Figure 3c). Heat treated Na0.44MnO2 samples generally present rod-like structures due to the preferential growth along the [0 0 1] direction [22]. The present finding is therefore in agreement with the reduced time and temperature of the thermal treatment for SC-NMO compared to SS-NMO. Indeed, as expected, the synthetic approach here proposed is a solution-based approach. Wet-chemistry techniques are well known to produce even rather complex oxides at relative low temperatures, compared to conventional solid-state synthesis, thanks to the homogeneous and intimate mixing of the metal ions in the liquid phase and the formation of a porous matrix composed of nanoparticles that can easily react at the solid state in subsequent thermal treatments [30]. In addition, compared to other wet-chemistry techniques, the solution combustion approach takes advantage of the exothermicity of the redox reaction involved in the precursor formation; the released heat of the combustion reaction may fulfill, at least locally, the energy requirement for the formation of the oxide matrix, thus allowing the preparation of single-phase materials at relatively lower temperatures and in a shorter time [26]. Figure 3. Scanning Electron Microscopy, SEM, micrographs of the SC-NMO as synthesized powder. The magnifications are: (a) 25.0 kx and (b) 100.0 kx; (c) Comparison of two micrographs acquired at the same SEM mag. (50.0 kx): the upper image refers to SS-NMO sample; the lower one to SC-NMO sample.PDF Image | Sodium-Ion Batteries Obtained through Urea Based

PDF Search Title:

Sodium-Ion Batteries Obtained through Urea BasedOriginal File Name Searched:

10281-250332.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Salt water flow battery technology with low cost and great energy density that can be used for power storage and thermal storage. Let us de-risk your production using our license. Our aqueous flow battery is less cost than Tesla Megapack and available faster. Redox flow battery. No membrane needed like with Vanadium, or Bromine. Salgenx flow battery

| CONTACT TEL: 608-238-6001 Email: greg@salgenx.com | RSS | AMP |