PDF Publication Title:

Text from PDF Page: 004

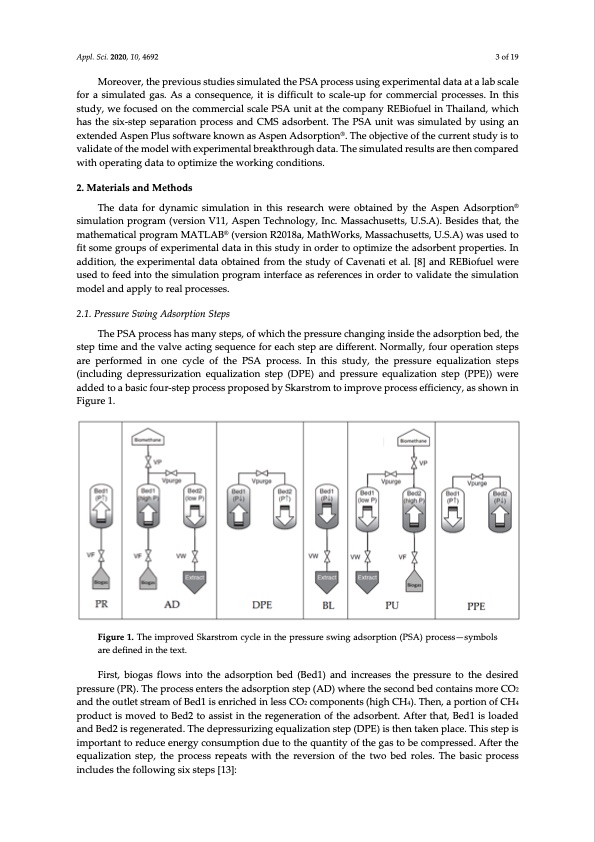

Appl. Sci. 2020, 10, 4692 3 of 19 Moreover, the previous studies simulated the PSA process using experimental data at a lab scale for a simulated gas. As a consequence, it is difficult to scale-up for commercial processes. In this study, we focused on the commercial scale PSA unit at the company REBiofuel in Thailand, which has the six-step separation process and CMS adsorbent. The PSA unit was simulated by using an extended Aspen Plus software known as Aspen Adsorption®. The objective of the current study is to validate of the model with experimental breakthrough data. The simulated results are then compared with operating data to optimize the working conditions. 2. Materials and Methods The data for dynamic simulation in this research were obtained by the Aspen Adsorption® simulation program (version V11, Aspen Technology, Inc. Massachusetts, U.S.A). Besides that, the mathematical program MATLAB® (version R2018a, MathWorks, Massachusetts, U.S.A) was used to fit some groups of experimental data in this study in order to optimize the adsorbent properties. In addition, the experimental data obtained from the study of Cavenati et al. [8] and REBiofuel were used to feed into the simulation program interface as references in order to validate the simulation model and apply to real processes. 2.1. Pressure Swing Adsorption Steps The PSA process has many steps, of which the pressure changing inside the adsorption bed, the step time and the valve acting sequence for each step are different. Normally, four operation steps are performed in one cycle of the PSA process. In this study, the pressure equalization steps (including depressurization equalization step (DPE) and pressure equalization step (PPE)) were added to a basic four-step process proposed by Skarstrom to improve process efficiency, as shown in Figure 1. Figure 1. The improved Skarstrom cycle in the pressure swing adsorption (PSA) process—symbols are defined in the text. First, biogas flows into the adsorption bed (Bed1) and increases the pressure to the desired pressure (PR). The process enters the adsorption step (AD) where the second bed contains more CO2 and the outlet stream of Bed1 is enriched in less CO2 components (high CH4). Then, a portion of CH4 product is moved to Bed2 to assist in the regeneration of the adsorbent. After that, Bed1 is loaded and Bed2 is regenerated. The depressurizing equalization step (DPE) is then taken place. This step is important to reduce energy consumption due to the quantity of the gas to be compressed. After the equalization step, the process repeats with the reversion of the two bed roles. The basic process includes the following six steps [13]:PDF Image | Biogas Six-Step Pressure Swing Adsorption

PDF Search Title:

Biogas Six-Step Pressure Swing AdsorptionOriginal File Name Searched:

applsci-10-04692.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |