PDF Publication Title:

Text from PDF Page: 005

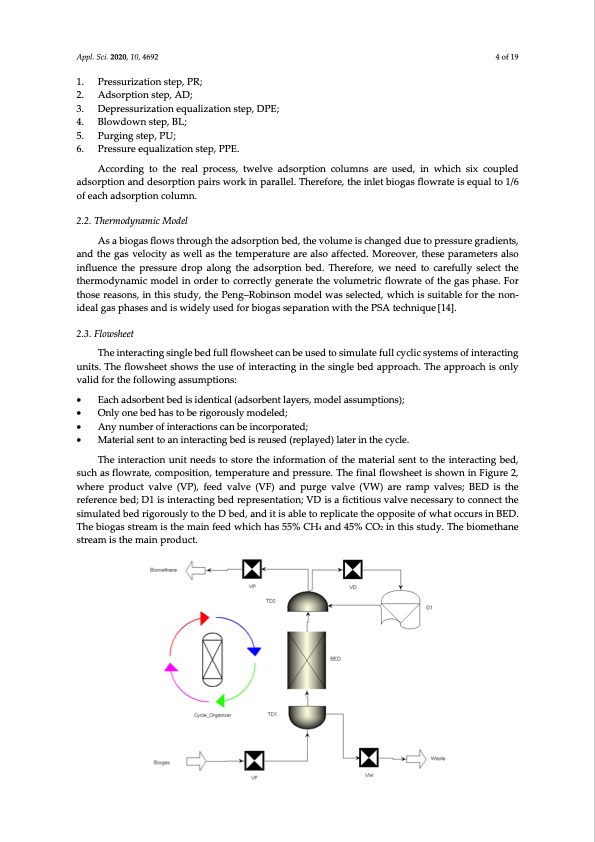

Appl. Sci. 2020, 10, 4692 4 of 19 1. Pressurization step, PR; 2. Adsorption step, AD; 3. Depressurization equalization step, DPE; 4. Blowdown step, BL; 5. Purging step, PU; 6. Pressure equalization step, PPE. According to the real process, twelve adsorption columns are used, in which six coupled adsorption and desorption pairs work in parallel. Therefore, the inlet biogas flowrate is equal to 1/6 of each adsorption column. 2.2. Thermodynamic Model As a biogas flows through the adsorption bed, the volume is changed due to pressure gradients, and the gas velocity as well as the temperature are also affected. Moreover, these parameters also influence the pressure drop along the adsorption bed. Therefore, we need to carefully select the thermodynamic model in order to correctly generate the volumetric flowrate of the gas phase. For those reasons, in this study, the Peng–Robinson model was selected, which is suitable for the non- ideal gas phases and is widely used for biogas separation with the PSA technique [14]. 2.3. Flowsheet The interacting single bed full flowsheet can be used to simulate full cyclic systems of interacting units. The flowsheet shows the use of interacting in the single bed approach. The approach is only valid for the following assumptions: • Each adsorbent bed is identical (adsorbent layers, model assumptions); • Only one bed has to be rigorously modeled; • Any number of interactions can be incorporated; • Material sent to an interacting bed is reused (replayed) later in the cycle. The interaction unit needs to store the information of the material sent to the interacting bed, such as flowrate, composition, temperature and pressure. The final flowsheet is shown in Figure 2, where product valve (VP), feed valve (VF) and purge valve (VW) are ramp valves; BED is the reference bed; D1 is interacting bed representation; VD is a fictitious valve necessary to connect the simulated bed rigorously to the D bed, and it is able to replicate the opposite of what occurs in BED. The biogas stream is the main feed which has 55% CH4 and 45% CO2 in this study. The biomethane stream is the main product.PDF Image | Biogas Six-Step Pressure Swing Adsorption

PDF Search Title:

Biogas Six-Step Pressure Swing AdsorptionOriginal File Name Searched:

applsci-10-04692.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |