PDF Publication Title:

Text from PDF Page: 011

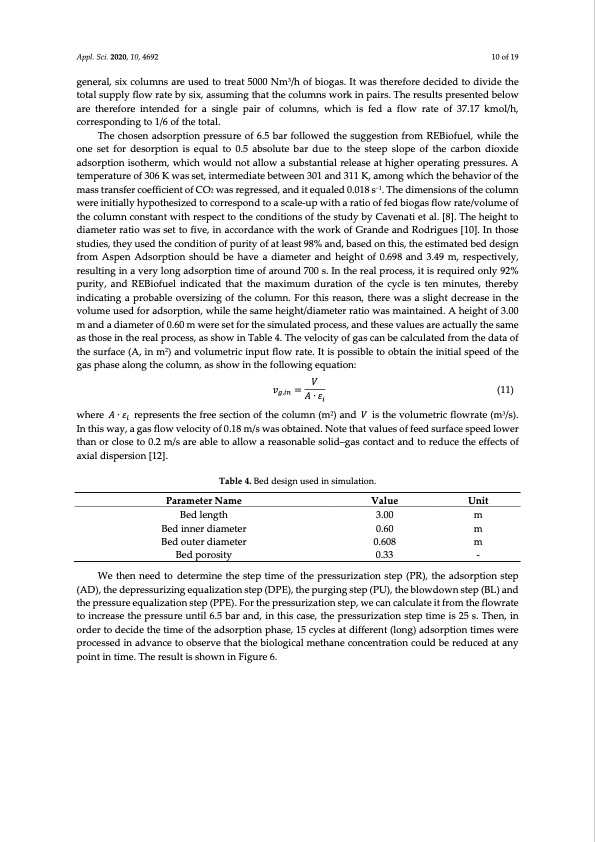

Appl. Sci. 2020, 10, 4692 10 of 19 general, six columns are used to treat 5000 Nm3/h of biogas. It was therefore decided to divide the total supply flow rate by six, assuming that the columns work in pairs. The results presented below are therefore intended for a single pair of columns, which is fed a flow rate of 37.17 kmol/h, corresponding to 1/6 of the total. The chosen adsorption pressure of 6.5 bar followed the suggestion from REBiofuel, while the one set for desorption is equal to 0.5 absolute bar due to the steep slope of the carbon dioxide adsorption isotherm, which would not allow a substantial release at higher operating pressures. A temperature of 306 K was set, intermediate between 301 and 311 K, among which the behavior of the mass transfer coefficient of CO2 was regressed, and it equaled 0.018 s−1. The dimensions of the column were initially hypothesized to correspond to a scale-up with a ratio of fed biogas flow rate/volume of the column constant with respect to the conditions of the study by Cavenati et al. [8]. The height to diameter ratio was set to five, in accordance with the work of Grande and Rodrigues [10]. In those studies, they used the condition of purity of at least 98% and, based on this, the estimated bed design from Aspen Adsorption should be have a diameter and height of 0.698 and 3.49 m, respectively, resulting in a very long adsorption time of around 700 s. In the real process, it is required only 92% purity, and REBiofuel indicated that the maximum duration of the cycle is ten minutes, thereby indicating a probable oversizing of the column. For this reason, there was a slight decrease in the volume used for adsorption, while the same height/diameter ratio was maintained. A height of 3.00 m and a diameter of 0.60 m were set for the simulated process, and these values are actually the same as those in the real process, as show in Table 4. The velocity of gas can be calculated from the data of the surface (A, in m2) and volumetric input flow rate. It is possible to obtain the initial speed of the gas phase along the column, as show in the following equation: 𝑣,= 𝑉 (11) 𝐴 ∙ 𝜀 where 𝐴 ∙ 𝜀 represents the free section of the column (m2) and 𝑉 is the volumetric flowrate (m3/s). In this way, a gas flow velocity of 0.18 m/s was obtained. Note that values of feed surface speed lower than or close to 0.2 m/s are able to allow a reasonable solid–gas contact and to reduce the effects of axial dispersion [12]. Table 4. Bed design used in simulation. Parameter Name Bed length Bed inner diameter Bed outer diameter Bed porosity Value Unit 3.00 m 0.60 m 0.608 m 0.33 - We then need to determine the step time of the pressurization step (PR), the adsorption step (AD), the depressurizing equalization step (DPE), the purging step (PU), the blowdown step (BL) and the pressure equalization step (PPE). For the pressurization step, we can calculate it from the flowrate to increase the pressure until 6.5 bar and, in this case, the pressurization step time is 25 s. Then, in order to decide the time of the adsorption phase, 15 cycles at different (long) adsorption times were processed in advance to observe that the biological methane concentration could be reduced at any point in time. The result is shown in Figure 6.PDF Image | Biogas Six-Step Pressure Swing Adsorption

PDF Search Title:

Biogas Six-Step Pressure Swing AdsorptionOriginal File Name Searched:

applsci-10-04692.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |