PDF Publication Title:

Text from PDF Page: 012

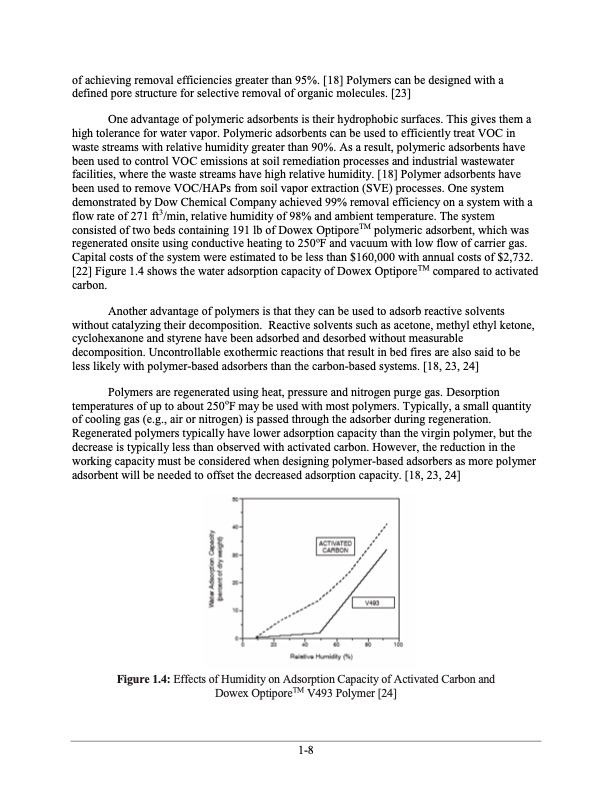

of achieving removal efficiencies greater than 95%. [18] Polymers can be designed with a defined pore structure for selective removal of organic molecules. [23] One advantage of polymeric adsorbents is their hydrophobic surfaces. This gives them a high tolerance for water vapor. Polymeric adsorbents can be used to efficiently treat VOC in waste streams with relative humidity greater than 90%. As a result, polymeric adsorbents have been used to control VOC emissions at soil remediation processes and industrial wastewater facilities, where the waste streams have high relative humidity. [18] Polymer adsorbents have been used to remove VOC/HAPs from soil vapor extraction (SVE) processes. One system demonstrated by Dow Chemical Company achieved 99% removal efficiency on a system with a flow rate of 271 ft3/min, relative humidity of 98% and ambient temperature. The system consisted of two beds containing 191 lb of Dowex OptiporeTM polymeric adsorbent, which was regenerated onsite using conductive heating to 250oF and vacuum with low flow of carrier gas. Capital costs of the system were estimated to be less than $160,000 with annual costs of $2,732. [22] Figure 1.4 shows the water adsorption capacity of Dowex OptiporeTM compared to activated carbon. Another advantage of polymers is that they can be used to adsorb reactive solvents without catalyzing their decomposition. Reactive solvents such as acetone, methyl ethyl ketone, cyclohexanone and styrene have been adsorbed and desorbed without measurable decomposition. Uncontrollable exothermic reactions that result in bed fires are also said to be less likely with polymer-based adsorbers than the carbon-based systems. [18, 23, 24] Polymers are regenerated using heat, pressure and nitrogen purge gas. Desorption temperatures of up to about 250oF may be used with most polymers. Typically, a small quantity of cooling gas (e.g., air or nitrogen) is passed through the adsorber during regeneration. Regenerated polymers typically have lower adsorption capacity than the virgin polymer, but the decrease is typically less than observed with activated carbon. However, the reduction in the working capacity must be considered when designing polymer-based adsorbers as more polymer adsorbent will be needed to offset the decreased adsorption capacity. [18, 23, 24] Figure 1.4: Effects of Humidity on Adsorption Capacity of Activated Carbon and Dowex OptiporeTM V493 Polymer [24] 1-8PDF Image | Carbon Adsorbers

PDF Search Title:

Carbon AdsorbersOriginal File Name Searched:

final_carbonadsorberschapter_7thedition.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |