PDF Publication Title:

Text from PDF Page: 023

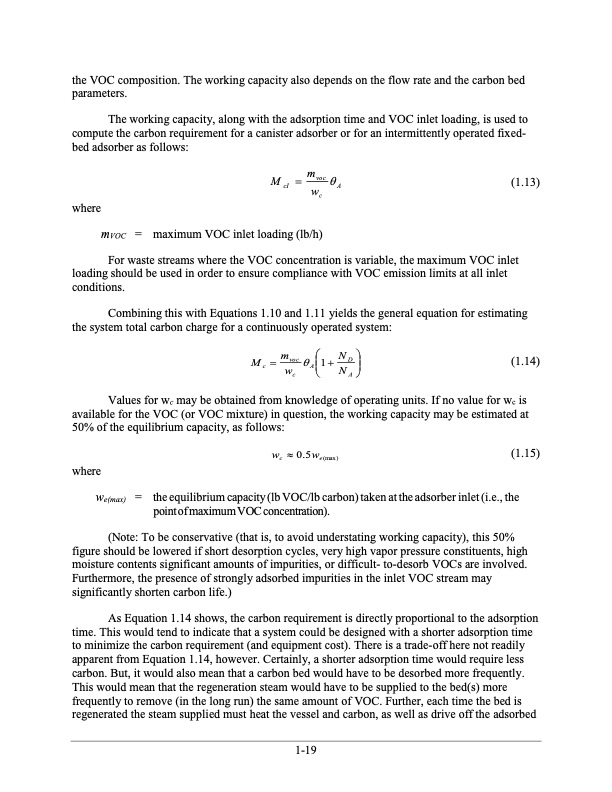

the VOC composition. The working capacity also depends on the flow rate and the carbon bed parameters. The working capacity, along with the adsorption time and VOC inlet loading, is used to compute the carbon requirement for a canister adsorber or for an intermittently operated fixed- bed adsorber as follows: M mvoc (1.13) cI wA c where mVOC = maximum VOC inlet loading (lb/h) For waste streams where the VOC concentration is variable, the maximum VOC inlet loading should be used in order to ensure compliance with VOC emission limits at all inlet conditions. Combining this with Equations 1.10 and 1.11 yields the general equation for estimating the system total carbon charge for a continuously operated system: mN Mc voc A1 D (1.14) Values for wc may be obtained from knowledge of operating units. If no value for wc is available for the VOC (or VOC mixture) in question, the working capacity may be estimated at 50% of the equilibrium capacity, as follows: wc 0.5we(max) (1.15) we(max) = the equilibrium capacity (lb VOC/lb carbon) taken at the adsorber inlet (i.e., the point of maximum VOC concentration). (Note: To be conservative (that is, to avoid understating working capacity), this 50% figure should be lowered if short desorption cycles, very high vapor pressure constituents, high moisture contents significant amounts of impurities, or difficult- to-desorb VOCs are involved. Furthermore, the presence of strongly adsorbed impurities in the inlet VOC stream may significantly shorten carbon life.) As Equation 1.14 shows, the carbon requirement is directly proportional to the adsorption time. This would tend to indicate that a system could be designed with a shorter adsorption time to minimize the carbon requirement (and equipment cost). There is a trade-off here not readily apparent from Equation 1.14, however. Certainly, a shorter adsorption time would require less carbon. But, it would also mean that a carbon bed would have to be desorbed more frequently. This would mean that the regeneration steam would have to be supplied to the bed(s) more frequently to remove (in the long run) the same amount of VOC. Further, each time the bed is regenerated the steam supplied must heat the vessel and carbon, as well as drive off the adsorbed where wc NA 1-19PDF Image | Carbon Adsorbers

PDF Search Title:

Carbon AdsorbersOriginal File Name Searched:

final_carbonadsorberschapter_7thedition.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |