PDF Publication Title:

Text from PDF Page: 029

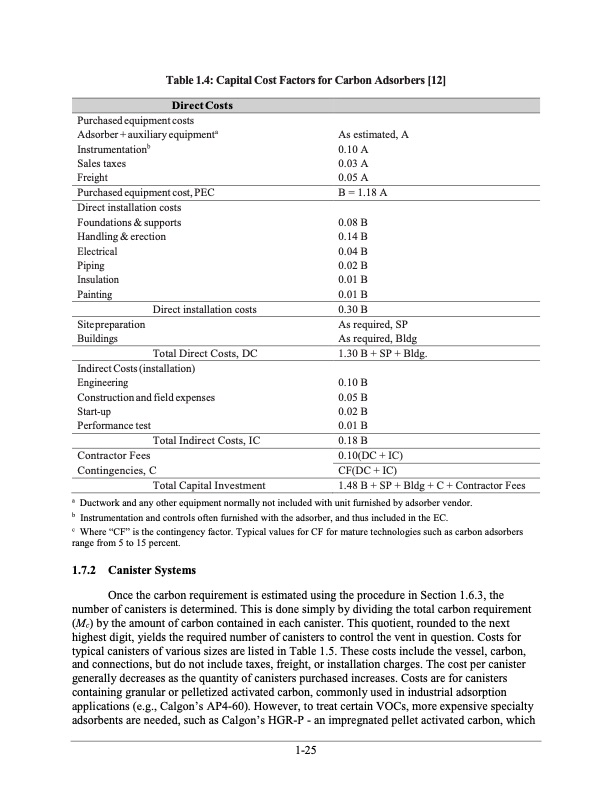

Table 1.4: Capital Cost Factors for Carbon Adsorbers [12] Direct Costs Purchased equipment costs Adsorber + auxiliary equipmenta Instrumentationb Sales taxes Freight Purchased equipment cost, PEC Direct installation costs Foundations & supports Handling & erection Electrical Piping Insulation Painting Direct installation costs Sitepreparation Buildings Total Direct Costs, DC Indirect Costs (installation) Engineering Construction and field expenses Start-up Performance test Total Indirect Costs, IC Contractor Fees Contingencies, C Total Capital Investment As estimated, A 0.10 A 0.03 A 0.05 A B = 1.18 A 0.08 B 0.14 B 0.04 B 0.02 B 0.01 B 0.01 B 0.30 B As required, SP As required, Bldg 1.30 B + SP + Bldg. 0.10 B 0.05 B 0.02 B 0.01 B 0.18 B 0.10(DC + IC) CF(DC + IC) 1.48 B + SP + Bldg + C + Contractor Fees a b c range from 5 to 15 percent. 1.7.2 Canister Systems Once the carbon requirement is estimated using the procedure in Section 1.6.3, the number of canisters is determined. This is done simply by dividing the total carbon requirement (Mc) by the amount of carbon contained in each canister. This quotient, rounded to the next highest digit, yields the required number of canisters to control the vent in question. Costs for typical canisters of various sizes are listed in Table 1.5. These costs include the vessel, carbon, and connections, but do not include taxes, freight, or installation charges. The cost per canister generally decreases as the quantity of canisters purchased increases. Costs are for canisters containing granular or pelletized activated carbon, commonly used in industrial adsorption applications (e.g., Calgon’s AP4-60). However, to treat certain VOCs, more expensive specialty adsorbents are needed, such as Calgon’s HGR-P - an impregnated pellet activated carbon, which Ductwork and any other equipment normally not included with unit furnished by adsorber vendor. Instrumentation and controls often furnished with the adsorber, and thus included in the EC. Where “CF” is the contingency factor. Typical values for CF for mature technologies such as carbon adsorbers 1-25PDF Image | Carbon Adsorbers

PDF Search Title:

Carbon AdsorbersOriginal File Name Searched:

final_carbonadsorberschapter_7thedition.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |