PDF Publication Title:

Text from PDF Page: 030

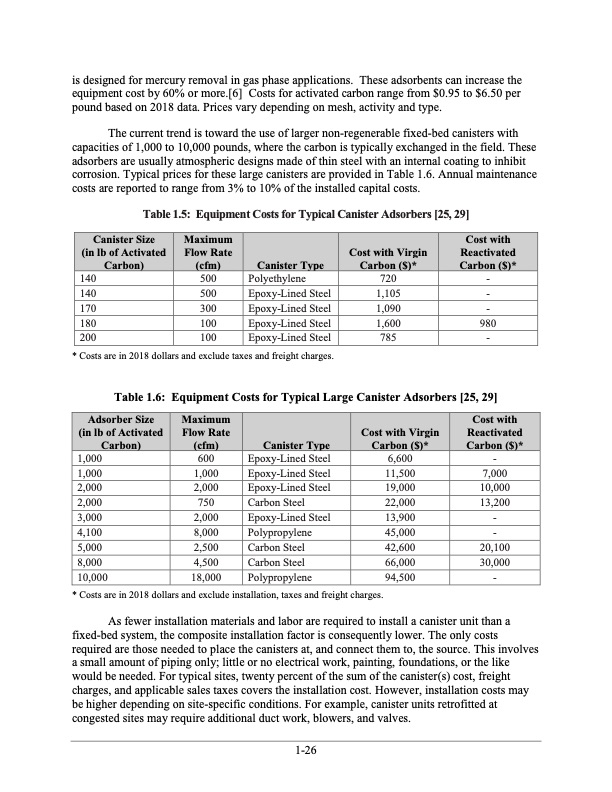

is designed for mercury removal in gas phase applications. These adsorbents can increase the equipment cost by 60% or more.[6] Costs for activated carbon range from $0.95 to $6.50 per pound based on 2018 data. Prices vary depending on mesh, activity and type. The current trend is toward the use of larger non-regenerable fixed-bed canisters with capacities of 1,000 to 10,000 pounds, where the carbon is typically exchanged in the field. These adsorbers are usually atmospheric designs made of thin steel with an internal coating to inhibit corrosion. Typical prices for these large canisters are provided in Table 1.6. Annual maintenance costs are reported to range from 3% to 10% of the installed capital costs. Table 1.5: Equipment Costs for Typical Canister Adsorbers [25, 29] Canister Size (in lb of Activated Carbon) 140 500 140 500 170 300 180 100 200 100 Polyethylene Epoxy-Lined Steel Epoxy-Lined Steel Epoxy-Lined Steel Epoxy-Lined Steel 720 - 1,105 - 1,090 - 1,600 980 785 - Maximum Flow Rate (cfm) * Costs are in 2018 dollars and exclude taxes and freight charges. Table 1.6: Equipment Costs for Typical Large Canister Adsorbers [25, 29] Adsorber Size (in lb of Activated Carbon) Maximum Flow Rate (cfm) Canister Type Cost with Virgin Carbon ($)* Cost with Reactivated Carbon ($)* 1,000 600 1,000 1,000 2,000 2,000 2,000 750 3,000 2,000 4,100 8,000 5,000 2,500 8,000 4,500 10,000 18,000 Epoxy-Lined Steel Epoxy-Lined Steel Epoxy-Lined Steel Carbon Steel Epoxy-Lined Steel Polypropylene Carbon Steel Carbon Steel Polypropylene 6,600 11,500 19,000 22,000 13,900 45,000 42,600 66,000 94,500 - 7,000 10,000 13,200 - - 20,100 30,000 - * Costs are in 2018 dollars and exclude installation, taxes and freight charges. Canister Type As fewer installation materials and labor are required to install a canister unit than a fixed-bed system, the composite installation factor is consequently lower. The only costs required are those needed to place the canisters at, and connect them to, the source. This involves a small amount of piping only; little or no electrical work, painting, foundations, or the like would be needed. For typical sites, twenty percent of the sum of the canister(s) cost, freight charges, and applicable sales taxes covers the installation cost. However, installation costs may be higher depending on site-specific conditions. For example, canister units retrofitted at congested sites may require additional duct work, blowers, and valves. Cost with Virgin Carbon ($)* Cost with Reactivated Carbon ($)* 1-26PDF Image | Carbon Adsorbers

PDF Search Title:

Carbon AdsorbersOriginal File Name Searched:

final_carbonadsorberschapter_7thedition.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |