PDF Publication Title:

Text from PDF Page: 031

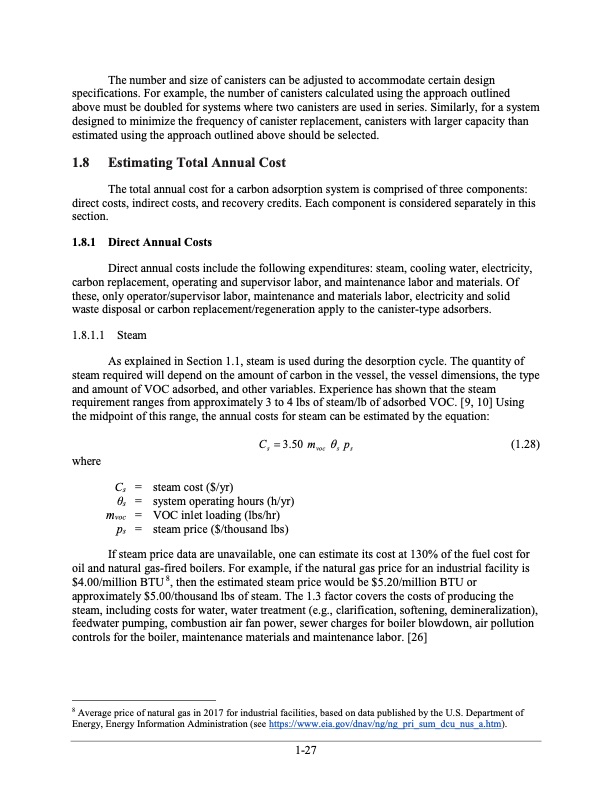

The number and size of canisters can be adjusted to accommodate certain design specifications. For example, the number of canisters calculated using the approach outlined above must be doubled for systems where two canisters are used in series. Similarly, for a system designed to minimize the frequency of canister replacement, canisters with larger capacity than estimated using the approach outlined above should be selected. 1.8 Estimating Total Annual Cost The total annual cost for a carbon adsorption system is comprised of three components: direct costs, indirect costs, and recovery credits. Each component is considered separately in this section. 1.8.1 Direct Annual Costs Direct annual costs include the following expenditures: steam, cooling water, electricity, carbon replacement, operating and supervisor labor, and maintenance labor and materials. Of these, only operator/supervisor labor, maintenance and materials labor, electricity and solid waste disposal or carbon replacement/regeneration apply to the canister-type adsorbers. 1.8.1.1 Steam As explained in Section 1.1, steam is used during the desorption cycle. The quantity of steam required will depend on the amount of carbon in the vessel, the vessel dimensions, the type and amount of VOC adsorbed, and other variables. Experience has shown that the steam requirement ranges from approximately 3 to 4 lbs of steam/lb of adsorbed VOC. [9, 10] Using the midpoint of this range, the annual costs for steam can be estimated by the equation: where Cs = θs = mvoc = ps = Cs 3.50 mvoc s ps steam cost ($/yr) system operating hours (h/yr) VOC inlet loading (lbs/hr) steam price ($/thousand lbs) (1.28) If steam price data are unavailable, one can estimate its cost at 130% of the fuel cost for oil and natural gas-fired boilers. For example, if the natural gas price for an industrial facility is $4.00/million BTU 8, then the estimated steam price would be $5.20/million BTU or approximately $5.00/thousand lbs of steam. The 1.3 factor covers the costs of producing the steam, including costs for water, water treatment (e.g., clarification, softening, demineralization), feedwater pumping, combustion air fan power, sewer charges for boiler blowdown, air pollution controls for the boiler, maintenance materials and maintenance labor. [26] 8 Average price of natural gas in 2017 for industrial facilities, based on data published by the U.S. Department of Energy, Energy Information Administration (see https://www.eia.gov/dnav/ng/ng_pri_sum_dcu_nus_a.htm). 1-27PDF Image | Carbon Adsorbers

PDF Search Title:

Carbon AdsorbersOriginal File Name Searched:

final_carbonadsorberschapter_7thedition.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |