PDF Publication Title:

Text from PDF Page: 032

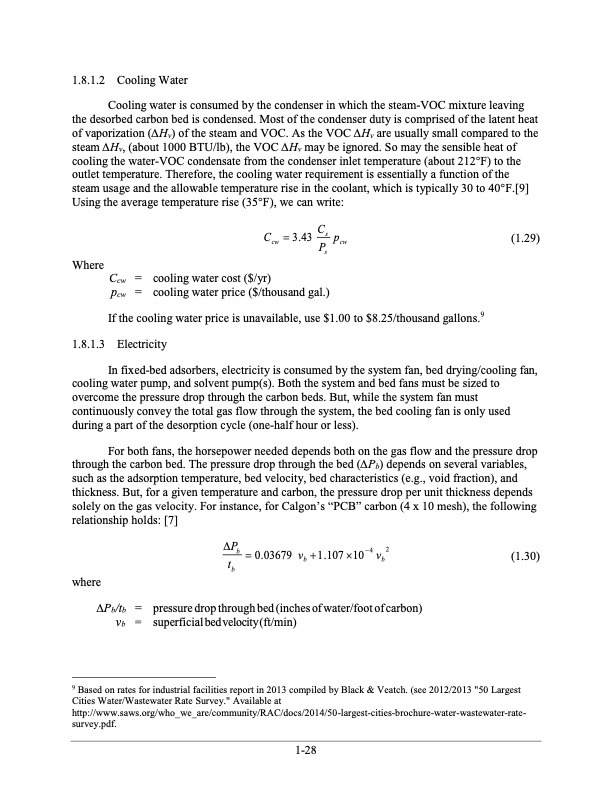

1.8.1.2 Cooling Water Cooling water is consumed by the condenser in which the steam-VOC mixture leaving the desorbed carbon bed is condensed. Most of the condenser duty is comprised of the latent heat of vaporization (∆Hv) of the steam and VOC. As the VOC ∆Hv are usually small compared to the steam ∆Hv, (about 1000 BTU/lb), the VOC ∆Hv may be ignored. So may the sensible heat of cooling the water-VOC condensate from the condenser inlet temperature (about 212°F) to the outlet temperature. Therefore, the cooling water requirement is essentially a function of the steam usage and the allowable temperature rise in the coolant, which is typically 30 to 40°F.[9] Using the average temperature rise (35°F), we can write: Where where ∆Pb/tb = Ccw = pcw = Ccw3.43Cs pcw P cooling water cost ($/yr) cooling water price ($/thousand gal.) (1.29) If the cooling water price is unavailable, use $1.00 to $8.25/thousand gallons.9 1.8.1.3 Electricity In fixed-bed adsorbers, electricity is consumed by the system fan, bed drying/cooling fan, cooling water pump, and solvent pump(s). Both the system and bed fans must be sized to overcome the pressure drop through the carbon beds. But, while the system fan must continuously convey the total gas flow through the system, the bed cooling fan is only used during a part of the desorption cycle (one-half hour or less). For both fans, the horsepower needed depends both on the gas flow and the pressure drop through the carbon bed. The pressure drop through the bed (∆Pb) depends on several variables, such as the adsorption temperature, bed velocity, bed characteristics (e.g., void fraction), and thickness. But, for a given temperature and carbon, the pressure drop per unit thickness depends solely on the gas velocity. For instance, for Calgon’s “PCB” carbon (4 x 10 mesh), the following relationship holds: [7] P b 0.03679v1.107104v2 (1.30) tbb b pressure drop through bed (inches of water/foot of carbon) vb = superficialbedvelocity(ft/min) s 9 Based on rates for industrial facilities report in 2013 compiled by Black & Veatch. (see 2012/2013 "50 Largest Cities Water/Wastewater Rate Survey." Available at http://www.saws.org/who_we_are/community/RAC/docs/2014/50-largest-cities-brochure-water-wastewater-rate- survey.pdf. 1-28PDF Image | Carbon Adsorbers

PDF Search Title:

Carbon AdsorbersOriginal File Name Searched:

final_carbonadsorberschapter_7thedition.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |