PDF Publication Title:

Text from PDF Page: 033

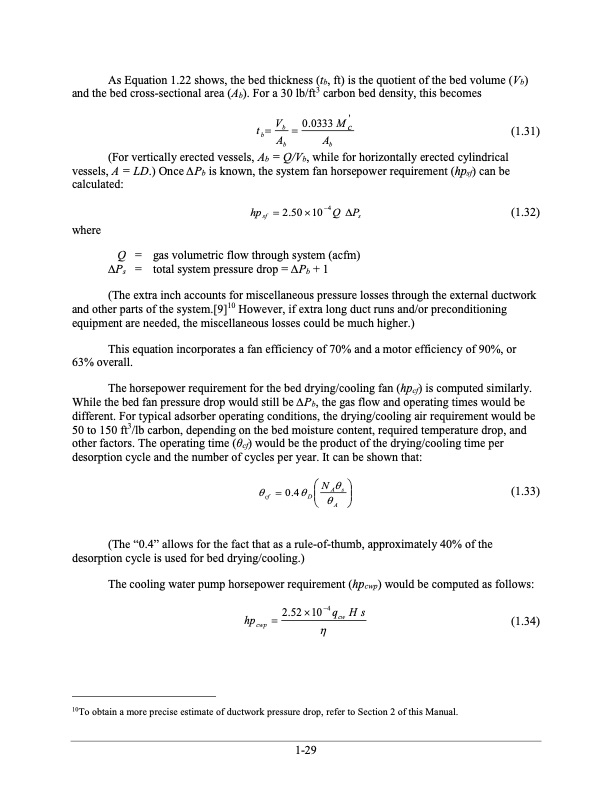

As Equation 1.22 shows, the bed thickness (tb, ft) is the quotient of the bed volume (Vb) and the bed cross-sectional area (Ab). For a 30 lb/ft3 carbon bed density, this becomes V b 0 . 0 3 3 3 M c' tb A A bb (For vertically erected vessels, Ab = Q/Vb, while for horizontally erected cylindrical vessels, A = LD.) Once ∆Pb is known, the system fan horsepower requirement (hpsf) can be calculated: (1.31) (1.32) where hp 2.50104QP sf s gas volumetric flow through system (acfm) total system pressure drop = ∆Pb + 1 Q = ∆Ps = (The extra inch accounts for miscellaneous pressure losses through the external ductwork and other parts of the system.[9]10 However, if extra long duct runs and/or preconditioning equipment are needed, the miscellaneous losses could be much higher.) This equation incorporates a fan efficiency of 70% and a motor efficiency of 90%, or 63% overall. The horsepower requirement for the bed drying/cooling fan (hpcf) is computed similarly. While the bed fan pressure drop would still be ∆Pb, the gas flow and operating times would be different. For typical adsorber operating conditions, the drying/cooling air requirement would be 50 to 150 ft3/lb carbon, depending on the bed moisture content, required temperature drop, and other factors. The operating time (θcf) would be the product of the drying/cooling time per desorption cycle and the number of cycles per year. It can be shown that: (1.33) N cf 0.4D A s A (The “0.4” allows for the fact that as a rule-of-thumb, approximately 40% of the desorption cycle is used for bed drying/cooling.) The cooling water pump horsepower requirement (hpcwp) would be computed as follows: 2.52104qcw Hs (1.34) 10To obtain a more precise estimate of ductwork pressure drop, refer to Section 2 of this Manual. 1-29 hp cwpPDF Image | Carbon Adsorbers

PDF Search Title:

Carbon AdsorbersOriginal File Name Searched:

final_carbonadsorberschapter_7thedition.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |