PDF Publication Title:

Text from PDF Page: 034

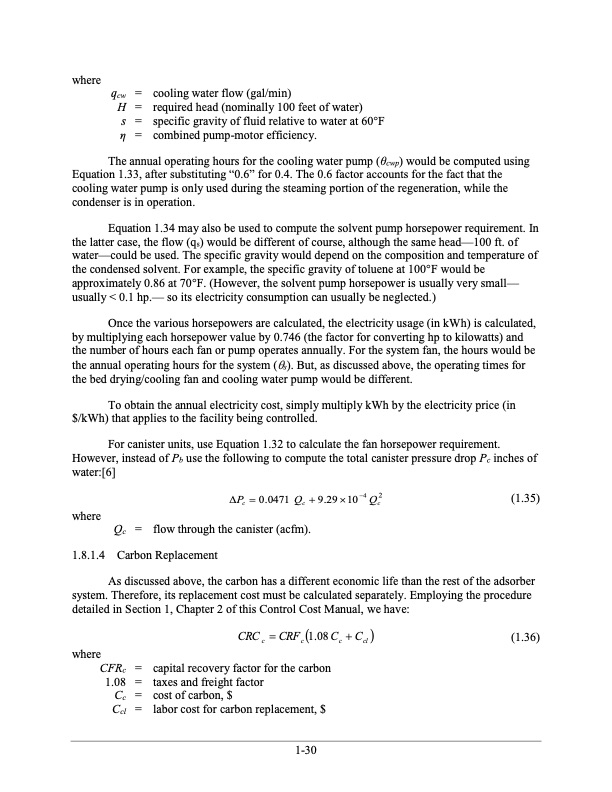

where qcw = H = s = η = cooling water flow (gal/min) required head (nominally 100 feet of water) specific gravity of fluid relative to water at 60°F combined pump-motor efficiency. The annual operating hours for the cooling water pump (θcwp) would be computed using Equation 1.33, after substituting “0.6” for 0.4. The 0.6 factor accounts for the fact that the cooling water pump is only used during the steaming portion of the regeneration, while the condenser is in operation. Equation 1.34 may also be used to compute the solvent pump horsepower requirement. In the latter case, the flow (qs) would be different of course, although the same head—100 ft. of water—could be used. The specific gravity would depend on the composition and temperature of the condensed solvent. For example, the specific gravity of toluene at 100°F would be approximately 0.86 at 70°F. (However, the solvent pump horsepower is usually very small— usually < 0.1 hp.— so its electricity consumption can usually be neglected.) Once the various horsepowers are calculated, the electricity usage (in kWh) is calculated, by multiplying each horsepower value by 0.746 (the factor for converting hp to kilowatts) and the number of hours each fan or pump operates annually. For the system fan, the hours would be the annual operating hours for the system (s). But, as discussed above, the operating times for the bed drying/cooling fan and cooling water pump would be different. To obtain the annual electricity cost, simply multiply kWh by the electricity price (in $/kWh) that applies to the facility being controlled. For canister units, use Equation 1.32 to calculate the fan horsepower requirement. However, instead of Pb use the following to compute the total canister pressure drop Pc inches of water:[6] P 0.0471 Q 9.29104 Q2 ccc where Qc = flow through the canister (acfm). (1.35) 1.8.1.4 Carbon Replacement As discussed above, the carbon has a different economic life than the rest of the adsorber system. Therefore, its replacement cost must be calculated separately. Employing the procedure detailed in Section 1, Chapter 2 of this Control Cost Manual, we have: where CFRc = 1.08 = Cc = Ccl = CRCc CRFc1.08Cc Ccl capital recovery factor for the carbon taxes and freight factor cost of carbon, $ labor cost for carbon replacement, $ (1.36) 1-30PDF Image | Carbon Adsorbers

PDF Search Title:

Carbon AdsorbersOriginal File Name Searched:

final_carbonadsorberschapter_7thedition.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |