PDF Publication Title:

Text from PDF Page: 038

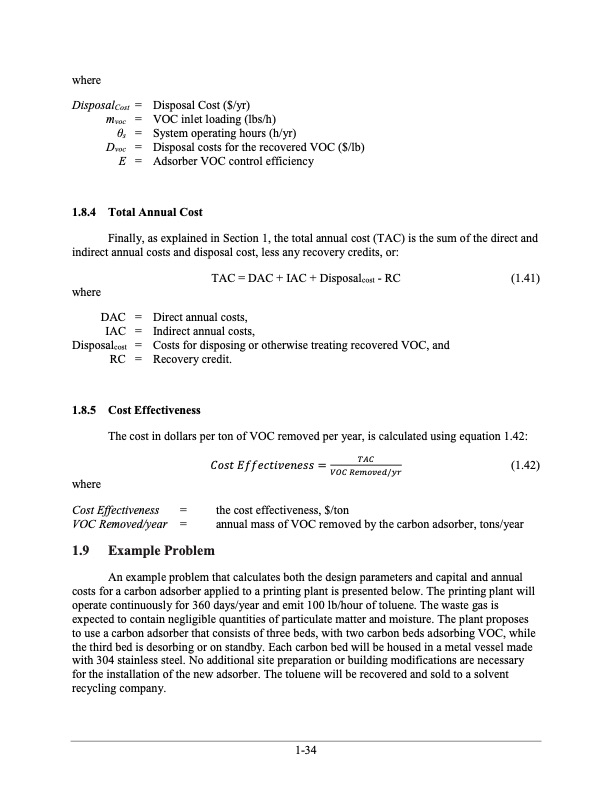

where DisposalCost = mvoc = θs = Dvoc = E = Disposal Cost ($/yr) VOC inlet loading (lbs/h) System operating hours (h/yr) Disposal costs for the recovered VOC ($/lb) Adsorber VOC control efficiency 1.8.4 Total Annual Cost Finally, as explained in Section 1, the total annual cost (TAC) is the sum of the direct and indirect annual costs and disposal cost, less any recovery credits, or: where DAC = IAC = Disposalcost = RC = 1.8.5 Cost Effectiveness TAC = DAC + IAC + Disposalcost - RC Direct annual costs, Indirect annual costs, Costs for disposing or otherwise treating recovered VOC, and Recovery credit. (1.41) The cost in dollars per ton of VOC removed per year, is calculated using equation 1.42: 𝐶𝑜𝑠𝑡 𝐸𝑓𝑓𝑒𝑐𝑡𝑖𝑣𝑒𝑛𝑒𝑠𝑠 = 𝑇𝐴𝐶 (1.42) 𝑉𝑂𝐶 𝑅𝑒𝑚𝑜𝑣𝑒𝑑/𝑦𝑟 where Cost Effectiveness = the cost effectiveness, $/ton VOC Removed/year = annual mass of VOC removed by the carbon adsorber, tons/year 1.9 Example Problem An example problem that calculates both the design parameters and capital and annual costs for a carbon adsorber applied to a printing plant is presented below. The printing plant will operate continuously for 360 days/year and emit 100 lb/hour of toluene. The waste gas is expected to contain negligible quantities of particulate matter and moisture. The plant proposes to use a carbon adsorber that consists of three beds, with two carbon beds adsorbing VOC, while the third bed is desorbing or on standby. Each carbon bed will be housed in a metal vessel made with 304 stainless steel. No additional site preparation or building modifications are necessary for the installation of the new adsorber. The toluene will be recovered and sold to a solvent recycling company. 1-34PDF Image | Carbon Adsorbers

PDF Search Title:

Carbon AdsorbersOriginal File Name Searched:

final_carbonadsorberschapter_7thedition.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |