PDF Publication Title:

Text from PDF Page: 004

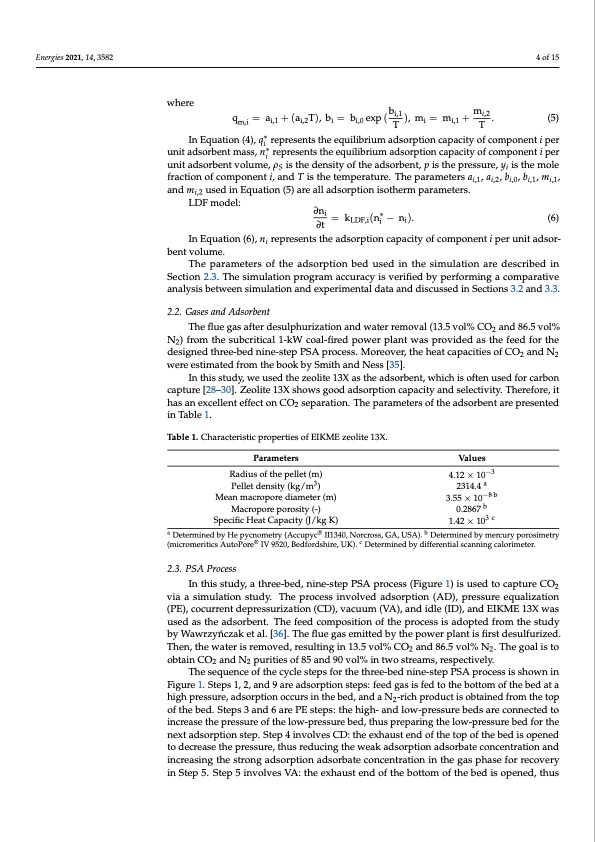

Energies 2021, 14, 3582 4 of 15 where qm,i = ai,1+(ai,2T), bi = bi,0exp(bi,1), mi = mi,1+mi,2. (5) TT In Equation (4), qi∗ represents the equilibrium adsorption capacity of component i per unit adsorbent mass, ni∗ represents the equilibrium adsorption capacity of component i per unit adsorbent volume, ρS is the density of the adsorbent, p is the pressure, yi is the mole fraction of component i, and T is the temperature. The parameters ai,1, ai,2, bi,0, bi,1, mi,1, and mi,2 used in Equation (5) are all adsorption isotherm parameters. LDF model: ∂ni = kLDF,i(ni∗ − ni). (6) ∂t In Equation (6), ni represents the adsorption capacity of component i per unit adsor- bent volume. The parameters of the adsorption bed used in the simulation are described in Section 2.3. The simulation program accuracy is verified by performing a comparative analysis between simulation and experimental data and discussed in Sections 3.2 and 3.3. 2.2. Gases and Adsorbent The flue gas after desulphurization and water removal (13.5 vol% CO2 and 86.5 vol% N2) from the subcritical 1-kW coal-fired power plant was provided as the feed for the designed three-bed nine-step PSA process. Moreover, the heat capacities of CO2 and N2 were estimated from the book by Smith and Ness [35]. In this study, we used the zeolite 13X as the adsorbent, which is often used for carbon capture [28–30]. Zeolite 13X shows good adsorption capacity and selectivity. Therefore, it has an excellent effect on CO2 separation. The parameters of the adsorbent are presented in Table 1. Table 1. Characteristic properties of EIKME zeolite 13X. Parameters Radius of the pellet (m) Pellet density (kg/m3) Mean macropore diameter (m) Macropore porosity (-) Specific Heat Capacity (J/kg K) Values 4.12 × 10−3 2314.4 a 3.55 × 10−8 b 0.2867 b 1.42 × 103 c a Determined by He pycnometry (Accupyc® II1340, Norcross, GA, USA). b Determined by mercury porosimetry (micromeritics AutoPore® IV 9520, Bedfordshire, UK). c Determined by differential scanning calorimeter. 2.3. PSA Process In this study, a three-bed, nine-step PSA process (Figure 1) is used to capture CO2 via a simulation study. The process involved adsorption (AD), pressure equalization (PE), cocurrent depressurization (CD), vacuum (VA), and idle (ID), and EIKME 13X was used as the adsorbent. The feed composition of the process is adopted from the study byWawrzyn ́czaketal.[36].Thefluegasemittedbythepowerplantisfirstdesulfurized. Then, the water is removed, resulting in 13.5 vol% CO2 and 86.5 vol% N2. The goal is to obtain CO2 and N2 purities of 85 and 90 vol% in two streams, respectively. The sequence of the cycle steps for the three-bed nine-step PSA process is shown in Figure 1. Steps 1, 2, and 9 are adsorption steps: feed gas is fed to the bottom of the bed at a high pressure, adsorption occurs in the bed, and a N2-rich product is obtained from the top of the bed. Steps 3 and 6 are PE steps: the high- and low-pressure beds are connected to increase the pressure of the low-pressure bed, thus preparing the low-pressure bed for the next adsorption step. Step 4 involves CD: the exhaust end of the top of the bed is opened to decrease the pressure, thus reducing the weak adsorption adsorbate concentration and increasing the strong adsorption adsorbate concentration in the gas phase for recovery in Step 5. Step 5 involves VA: the exhaust end of the bottom of the bed is opened, thusPDF Image | CO2 captured from flue gas using the PSA process

PDF Search Title:

CO2 captured from flue gas using the PSA processOriginal File Name Searched:

energies-14-03582-v2.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |