PDF Publication Title:

Text from PDF Page: 005

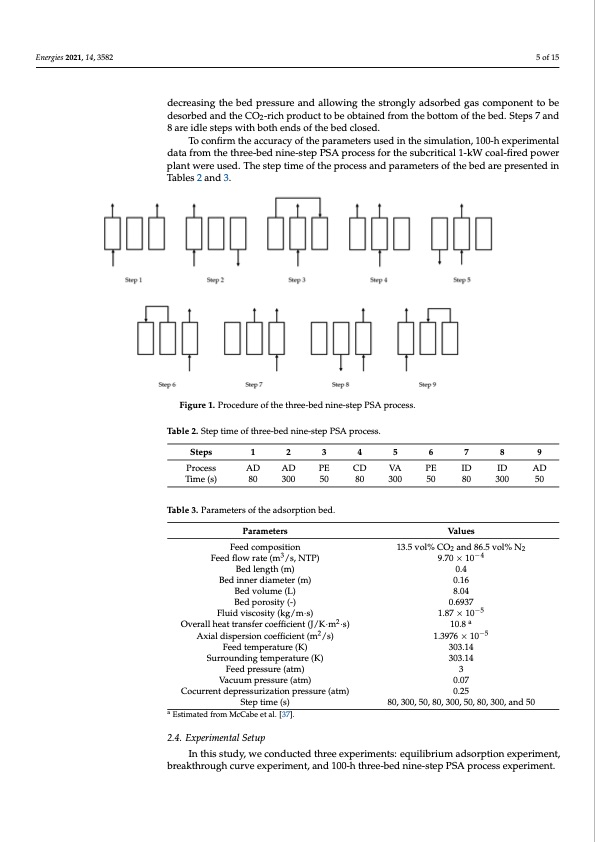

Energies 2021, 14, 3582 a high pressure, adsorption occurs in the bed, and a N2-rich product is obtained from the top of the bed. Steps 3 and 6 are PE steps: the high- and low-pressure beds are connected to increase the pressure of the low-pressure bed, thus preparing the low-pressure bed for the next adsorption step. Step 4 involves CD: the exhaust end of the top of the bed is opened to decrease the pressure, thus reducing the weak adsorption adsorbate concentra- tion and increasing the strong adsorption adsorbate concentration in the gas phase for recovery in Step 5. Step 5 involves VA: the exhaust end of the bottom of the bed is opened, thus decreasing the bed pressure and allowing the strongly adsorbed gas component to be desorbed and the CO2-rich product to be obtained from the bottom of the bed. Steps 7 desorbed and the CO -rich product to be obtained from the bottom of the bed. Steps 7 and and 8 are idle steps w2ith both ends of the bed closed. 8 are idle steps with both ends of the bed closed. To confirm the accuracy of the parameters used in the simulation, 100-h experimental To confirm the accuracy of the parameters used in the simulation, 100-h experimental data from the three-bed nine-step PSA process for the subcritical 1-kW coal-fired power 5 of 15 decreasing the bed pressure and allowing the strongly adsorbed gas component to be data from the three-bed nine-step PSA process for the subcritical 1-kW coal-fired power plant were used. The step time of the process and parameters of the bed are presented in plant were used. The step time of the process and parameters of the bed are presented in Tables 2 and 3. Tables 2 and 3. Figure 1. Procedure of the three-bed nine-step PSA process. Figure 1. Procedure of the three-bed nine-step PSA process. Table 2. Step time of three-bed nine-step PSA process. Table 2. Step time of three-bed nine-step PSA process. StepSsteps112233445566 77 8 9 ProcPersoscess AD ADAD AD PE 300 PE 50 CD CD VAVA 80 300 PEPE IDID IID AD Time (s) 80 50 50 80 300 50 Time (s) 80 Table 3. Parameters of the adsorption bed. 300 80 300 50 80 300 50 Table 3. Parameters of the adsorption bed. Parameters Feed composition Values Parameters Values Feed composition 13.5 vol% CO2 and 86.5 vol% N2 Feed flow rate (m3/s, NTP) 13.5 vol% CO2 and 86.5 vol% N2 Feed flow rate (m3/s, NTP) 9.70 × 10−4 0.4 Bed length (m) Bed length (m) BBeeddininner diametteerr(m(m) ) 0.4 0.16 Bed volume (L) 8.04 Bed volume (L) 8.04 Bed porosity (-) 0.6937 0.6937−5 Bed porosity (-) Fluid viscosity (kg/m·s) Fluid viscosity (kg/m·s) 1.87 × 10 1.87 × 1a 0−5 2 Overall heat transfer coefficient (J/K·m ·s) 10.8 Overall heat transfer coefficient (J/K· m2 ·s) Axial dispersion coefficient (m2/s) Axial dFisepeedrtseimonpecroaetuffrieci(eKn)t (m2/s) Surrounding temperature (K) Feed pressure (atm) Vacuum pressure (atm) Cocurrent depressurization pressure (atm) Step time (s) a Estimated from McCabe et al. [37]. 2.4. Experimental Setup 10.8 a 9.70 × 10−4 1.3976 × 10−5 1.3937063.1×410−5 303.14 3 0.07 0.25 80, 300, 50, 80, 300, 50, 80, 300, and 50 In this study, we conducted three experiments: equilibrium adsorption experiment, breakthrough curve experiment, and 100-h three-bed nine-step PSA process experiment.PDF Image | CO2 captured from flue gas using the PSA process

PDF Search Title:

CO2 captured from flue gas using the PSA processOriginal File Name Searched:

energies-14-03582-v2.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |