PDF Publication Title:

Text from PDF Page: 013

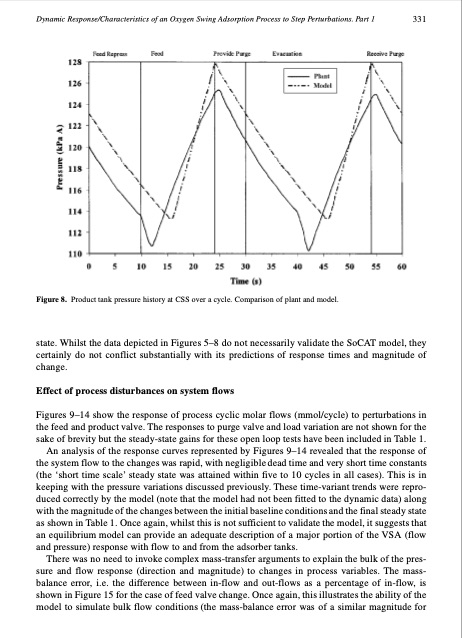

Dynamic Response/Characteristics of an Oxygen Swing Adsorption Process to Step Perturbations. Part 1 331 Figure 8. Product tank pressure history at CSS over a cycle. Comparison of plant and model. state. Whilst the data depicted in Figures 5–8 do not necessarily validate the SoCAT model, they certainly do not conflict substantially with its predictions of response times and magnitude of change. Effect of process disturbances on system flows Figures 9–14 show the response of process cyclic molar flows (mmol/cycle) to perturbations in the feed and product valve. The responses to purge valve and load variation are not shown for the sake of brevity but the steady-state gains for these open loop tests have been included in Table 1. An analysis of the response curves represented by Figures 9–14 revealed that the response of the system flow to the changes was rapid, with negligible dead time and very short time constants (the ‘short time scale’ steady state was attained within five to 10 cycles in all cases). This is in keeping with the pressure variations discussed previously. These time-variant trends were repro- duced correctly by the model (note that the model had not been fitted to the dynamic data) along with the magnitude of the changes between the initial baseline conditions and the final steady state as shown in Table 1. Once again, whilst this is not sufficient to validate the model, it suggests that an equilibrium model can provide an adequate description of a major portion of the VSA (flow and pressure) response with flow to and from the adsorber tanks. There was no need to invoke complex mass-transfer arguments to explain the bulk of the pres- sure and flow response (direction and magnitude) to changes in process variables. The mass- balance error, i.e. the difference between in-flow and out-flows as a percentage of in-flow, is shown in Figure 15 for the case of feed valve change. Once again, this illustrates the ability of the model to simulate bulk flow conditions (the mass-balance error was of a similar magnitude forPDF Image | Dynamic Response and Characteristics of an Oxygen Vacuum Swing Adsorption

PDF Search Title:

Dynamic Response and Characteristics of an Oxygen Vacuum Swing AdsorptionOriginal File Name Searched:

026361703322405051.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |