PDF Publication Title:

Text from PDF Page: 014

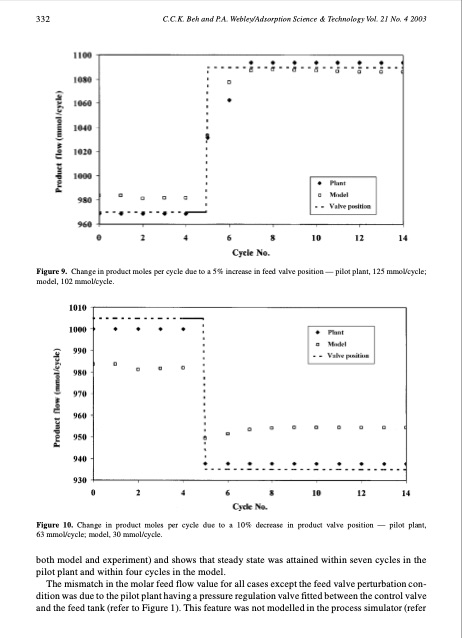

332 C.C.K. Beh and P.A. Webley/Adsorption Science & Technology Vol. 21 No. 4 2003 Figure 9. Change in product moles per cycle due to a 5% increase in feed valve position — pilot plant, 125 mmol/cycle; model, 102 mmol/cycle. Figure 10. Change in product moles per cycle due to a 10% decrease in product valve position — pilot plant, 63 mmol/cycle; model, 30 mmol/cycle. both model and experiment) and shows that steady state was attained within seven cycles in the pilot plant and within four cycles in the model. The mismatch in the molar feed flow value for all cases except the feed valve perturbation con- dition was due to the pilot plant having a pressure regulation valve fitted between the control valve and the feed tank (refer to Figure 1). This feature was not modelled in the process simulator (referPDF Image | Dynamic Response and Characteristics of an Oxygen Vacuum Swing Adsorption

PDF Search Title:

Dynamic Response and Characteristics of an Oxygen Vacuum Swing AdsorptionOriginal File Name Searched:

026361703322405051.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |